29 Jun 2015

Soybeans for On-farm Biodiesel Production

Mark Mordasky, owner of Rainbow Valley Farm in Orwell, Vermont has been growing soybeans as a cash crop and for on-farm biodiesel and animal feed since 2008. When fuel prices began to climb, Mark took initiative and started searching for an innovative and more cost efficient way to meet his farm’s energy demands. The Vermont Sustainable Jobs Fund was able to help Mark take his first steps towards sustainable biofuel production. Mark is able to press these soybeans after harvesting and make two distinct products, oil and meal. The meal is an instantly marketable product and can be sold as feedstock or organic fertilizer; the oil will be further processed into biodiesel.

Soybeans crops are well suited for biodiesel production in Vermont and perform best in heavy soil like those found in Addison County, as University of Vermont Extension Agronomist, Heather Darby explains. Soybeans don’t always do well in in light, well drained soils, and as with any crop the best way to understand the demands of any crops is to contact your University Extension and have your soil tested. Additionally, because soybeans are a legume, they produce nitrogen in association with bacteria, meaning that these crops don’t require the application of additional nitrogen to produce a high yield. These low input, high yield crops are fairly easy to grow, are well suited to the Vermont climate, and afford farmers flexible planting dates. Heather and the rest of the UVM Extension team have seen yields ranging from 35 bushels per acre to up to 85 bushels per acre with varying practices.

In the below video, Mike Mordasky shares his experience and knowledge of soybean production from planting through harvesting harvest and beyond to storage and the creation of the final products. In addition, Heather Darby shares here insights into maturity groupings, variety selection, and best growing practices.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

Algae produces more than half of the oxygen on the planet, while consuming vast amounts of heat-trapping carbon dioxide and taking up nutrients like nitrogen and phosphorous to make biomass and energy. The lipids, or oil, that algae produce can be extracted and processed into renewable fuels such as biodiesel. Algae are an excellent source of oil for making biodiesel, which could displace substantial volumes of petro-diesel for heating and transportation. Microalgae reproduce rapidly, and they grow on non-agricultural land, so they do not compete with food, feed, or fiber production.

The keys to commercializing algae for biofuel production include identifying and cultivating native species, optimizing growing conditions in natural and artificial environments and the efficient harvest and oil extraction of algal biomass. At the forefront of this algae biofuel research is Dr. Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. Dr. Dahiya has been searching for high lipid algae strains, and scaling those up to a level that could be available for commercial use, especially for biofuels.

“At GSR Solutions, we are looking at producing algae not just for biofuels, but combining it with waste water treatment and to produce other valued byproducts as well. This is very significant, because this would make algae production cost-effective. This would also help in nutrient recovery,” says Dahiya.

innovative new textbook that provides insight into the potential and current advances and benefits of biofuel

Some of the findings and knowledge afforded by Dr. Dahiya’s research are available in the new introductory textbook, Bioenergy: Biomass to Biofuels, which was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories. Dr. Dahiya will also be using this textbook as the basis for a University of Vermont Bioenergy Course offered for the 2015 fall semester.

In the below video, Vermont researchers and entrepreneurs demonstrate their innovations in algae to biofuel research and development.

For more algae bioenergy resources see the visit the Algae section of the Vermont Bioenergy Website.

Learn more about the mentioned UVM Bioenergy Course visit the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

For more information on the introductory textbook Bioenery; Biomass to Biofuels see our write up on the book here!

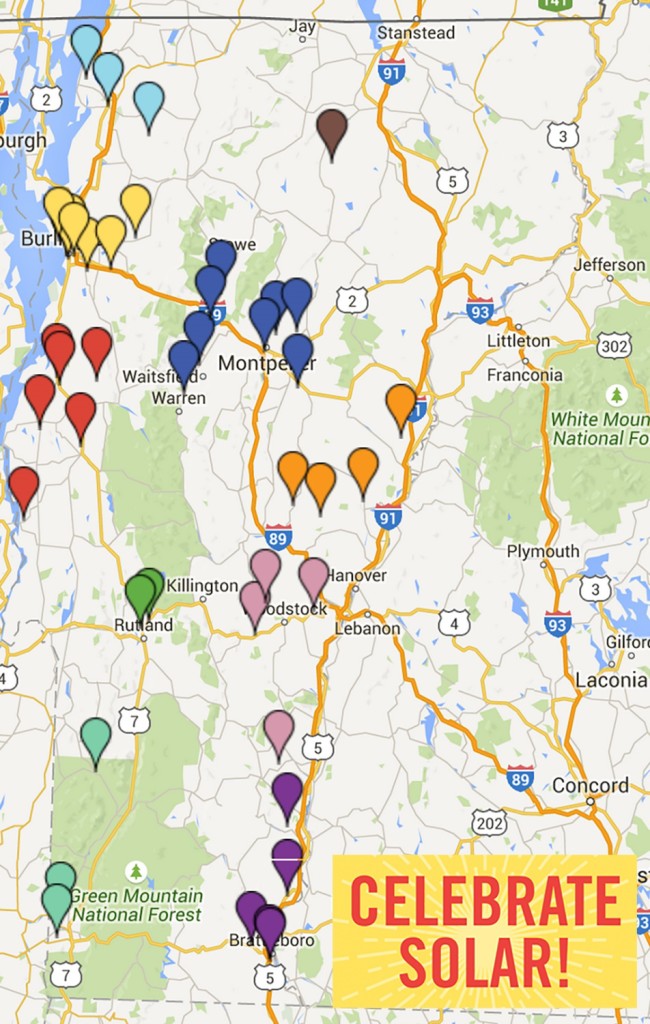

Vermont’s solar industry is lauding Governor Peter Shumlin’s proclamation of the third Saturday in June as “Celebrate Solar Day” in Vermont.

The solar proclamation, announced at the Whitcomb Farm in Essex, coincides with this June 20th, when solar projects in communities throughout Vermont will be open for public tours. June 20 is the weekend of the Summer Solstice.

Like open sugarhouse weekend in the spring and open art studio weekend in the fall, the inaugural summertime tours will give Vermonters the opportunity to get an up-close view of solar systems to learn about the technology, solar economics, and the benefits of solar to our community. Solar customers, host farmers, and owners will be on-hand to speak with the public.

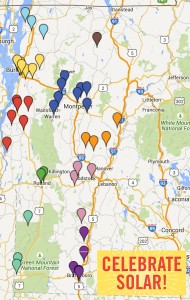

More than 50 systems across all regions of the state will be participating in Celebrate Solar Tours and a map of open tours can be found here. Many participating sites will host refreshments, music, or other entertainment. Other planned solar events include community walking tours of residential solar installations, miniature golf, a self-guided bike tour, and on-site yoga.

The Governor’s proclamation notes that “solar energy represented 99% of new electrical capacity in the state in 2014 and more than 5,000 Vermont customers have installed solar” through Vermont’s net metering program.

Further, it cites that the Vermont clean energy industries employ over 15,000 Vermonters, with solar providing “a broad spectrum of employment opportunities, helping retain and attract Vermonters working in manufacturing, installation, and sales, among other careers.”

The Whitcomb family is host to a 2.2 Megawatt solar farm that provides energy for Vermont’s SPEED program.

Among the solar sites open to tour June 20: iconic and sweet Vermont attractions like Cold Hollow Cider and Morse Farm Maple Sugarworks, high-tech attractions like Draker and Small Dog Electronics, agricultural farms like Champlain Orchards, shared community solar arrays, and some of Vermont’s highest producing solar farms.

At the announcement of the solar tours, Paul Brown, owner of Cold Hollow Cider in Waterbury Center, which has a 150kW system powering its operations, said of the event, “Folks know us and visit us for our cider and donuts. But we are thrilled to open up the field behind our cidery to share the benefits of solar technology to our business and our community. We’ll of course also be serving up some sweet treats for those who come by.”

About Celebrate Solar Tours – June 20

The first annual Celebrate Solar Tours on June 20 will feature public tours of more than 50 solar systems of varying size throughout the state. The public will have the opportunity to get an up-close understanding of the technology, economics and benefits to the community. Open systems will be designated with roadway signage and many will feature music, refreshments or other entertainment.

Contact: Ansley Bloomer

Ansley@revermont.org or 802-595-0723

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

01 Jun 2015

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”

In order to meet the goals set by Vermont’s comprehensive energy plan for Vermont to produce 90 percent of the state’s energy needs from renewables by 2050 and reduce Vermont’s greenhouse gas emissions by 50 percent from a 1990 baseline, Vermont farmers will have an important role to play. As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more important prompting statewide energy and agriculture collaborations. In the following episodes of Across the Fence, UVM Extension agricultural engineer and Vermont Bioenergy Initiative biofuels consultant, Chris Callahan, shares two stories about Vermont farmers who are rethinking their on-farm energy. In both examples UVM extension is able to work with the farmers to help make cleaner, renewable on-farm energy sources a practical solution that saves money and results in greenhouse gas reductions.

Learn more in a series of on-farm energy case studies produced by Vermont’s Farm to Plate Initiative.

19 May 2015

Mitigating Potential Biomass Feedstock Pests

The Vermont Bioenergy Initiative aims to connect diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution. As we move into the growing season, there are a variety of pests that can potentially affect sunflower, canola, and soybean biomass feedstock production. In this video a University of Vermont agronomist explains how to control theses potential biomass feedstock pests and increase crop, and eventually biofuel, yields without heavy reliance on pesticides and herbicides.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The database was originally created with funding from the U.S. Endowment for Forestry and Communities and further improvements were made with funding from the U.S. Department of Energy through the support of Vermont Senator Patrick Leahy. The re-tooled database is a user-friendly, interactive tool that will help collect and track information on a continuing basis. “This resource will provide stakeholders from a variety of backgrounds with a better understanding of the current demand for wood fuels as an energy source and the success of modern wood heating projects throughout North America,” said Adam Sherman, Manager of BERC at VEIC.

The database already contains more than 500 entries, but to ensure that this publicly available resource is accurate and up to date, BERC is asking for user participation. “We are committed to maintaining and building this database over time to ensure it remains a useful and reliable too, but this is a rapidly growing sector, so we need users to help,” said Sherman. “We need people to engage with the database; add new entries for facilities that have been missed and as new facilities come online, and edit existing entries that are incomplete.” With regular contributions, the database will continue to improve and grow.

With tens of thousands of annual visits and top Google search ranking, the BERC website is a high-visibility home for this important tool. The BERC database is designed to provide vital information on a specific subset of biomass energy facilities; community-scale biomass heating projects. The BERC database complements the Wood2Energy.org database that covers a broader spectrum of biomass energy facilities including power plants, sawmills, and pellet mills. Not only will the BERC database provide wood heating systems vendors the exposure and recognition for their projects, it also helps demonstrate that modern wood heating is becoming mainstream throughout North America. To learn more about using and contributing to the database visit www.biomasscenter.org/database.

About BERC

The Biomass Energy Resource Center (BERC) is a program of Vermont Energy Investment Corporation (VEIC). BERC works to advance the use of community-scale biomass energy throughout North America and beyond by providing technical consulting services, biomass energy program design and delivery, and education and outreach on benefits and best practices. BERC works with communities, federal, state and local governments, colleges and universities, businesses, utilities, and others to use local biomass resources, invest in local energy systems, and reduce the use of fossil heating fuels.

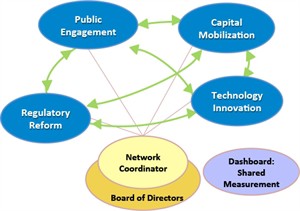

The EAN’s 4 Key Leverage Points of capital mobilization, public engagement, technology innovation, and regulatory reform

The Energy Action Network (EAN) is a community of a community of Green Mountain State stakeholders working to change the Vermont energy landscape “to end Vermont’s reliance on fossil fuels and to create clean, affordable energy and secure electric, heating, and transportation systems for the 21st century.” Their goals are consistent with the State of Vermont 2011 Comprehensive Energy Plan, which aims to meet 90% of Vermont’s energy needs through efficiency and renewable sources by 2050.

EAN has identified a series of pathways for Vermont for Vermont to accomplish the paradigm shift of 90% renewables by 2050. Membership is structured into working groups focused on four “leverage points” capital mobilization, public engagement, technology innovation, and regulatory reform. Current projects include alterations to Act 250, changes in zoning laws, programs to promote bringing rental properties into efficiency standards, and assessing current land use for its potential for bioenergy and solar projects.

One notable awareness vehicle, Brighter Vermont, encourages Vermonters to change the way common energy use and think more about where energy comes from. Read more about how Brighter Vermont helps change energy behavior. EAN also works with municipalities and recently helped Montpelier plan for a 15 year track to become the first state capital to accomplish all of its energy needs with renewable energy. On February 12, 2015 the Montpelier City council accepted and endorsed the plan to make Montpelier a “net zero” city.

Currently, EAN is working with the Vermont Sustainable Jobs Fund to expand the Vermont Energy Atlas website into the Community Energy Dashboard. The Dashboard will enable communities to understand their energy use and make clean energy choices and investments across all energy sectors—heating, transportation, and electricity. The Dashboard will make energy use visible and understandable to consumers and communities by showing town-level progress toward Vermont’s 90% renewables by 2050 goal. The Dashboard will also shows existing and potential renewable energy sites (solar, wind, hydro, biomass). We will provide updates as they develop. Stay tuned into the Vermont Bioenergy Field Notes blog and visit the Energy Action Network website to learn more.