Vermont Farmer Helps Others Produce Biofuel

Monday, September 14, 2015 The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

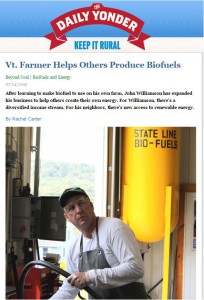

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Monday, June 1, 2015Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”

Vermont Bioenergy Initiative proves biofuel potential for state and concludes ten year project

Monday, November 2, 2015By: Ellen Kahler

VT Bioenergy Team – L to R (Chris Callahan – UVM Extension, Kirk Shields — Green Mountain Power, Christy Sterner – US DOE, Larry Scott – Ekolott Farm, Ellen Kahler – VSJF, John Williamson – Stateline Biofuels) at Green Mountain Power’s Energy Innovation Center in Rutland

Vermont can produce more of its own biofuel energy and the environmental and potential economic benefits of local bioenergy have been proven by the Vermont Bioenergy Initiative – a program of the Vermont Sustainable Jobs Fund. Since 2005, the Vermont Bioenergy Initiative has invested more than $2.5 million in innovative bioenergy research, projects, and people so Vermont can locally produce more of the state’s energy needs – from a variety of agricultural and algal feedstocks.

US Senator Patrick Leahy made the investment at this scale possible through Congressionally Directed Awards from the US Department of Energy (US DOE). The funding concludes in early 2016, at which point a complete impact report will be released by the Vermont Sustainable Jobs Fund, who has served as the intermediary between the US DOE and 52 individual Vermont bioenergy projects over the past ten years.

Research, development, and early stage demonstration projects have included:

- Investing in 2 on-farm methane digesters;

- Building farm-scale infrastructure to turn oilseed crops such as sunflowers into biodiesel to run farm tractors;

- Growing switchgrass and densifying it into “pucks” that are burned in a high efficiency commercial boiler instead of propane;

- Identifying the most lipid producing strains of native Vermont algae which can feed off the excess nutrients from methane digesters and can eventually be harvested to make biodiesel or jet fuel;

- Developing two “Biomass to Biofuels” college level courses which run repeatedly at UVM and VT Tech to inspire and train the next generation of bioenergy experts and technicians;

- Exploring the logistics of bulk wood pellet delivery systems to Vermonters’ homes;

- Organizing a number of learning opportunities and conferences for oilseed, grass and algae researchers, farmers and entrepreneurs to attend;

- Providing agronomic and engineering support to oilseed and grass farmers;

- Educating the general public about why the local production for local use of energy crops from Vermont farms and forests makes good economic and ecological sense.

VT Bioenergy Team 2 – L to R (Roger Rainville – Borderview Farm, Christy Sterner – US DOE, Heather Darby – UVM Extension, Natasha Rainville – Borderview Farm) at Borderview Farm, Alburgh VT

The Vermont Bioenergy Initiative is a unique effort and one that is gaining resonance in other parts of rural America. The initiative’s resource website, www.VermontBioenergy.com is utilized by biofuel producers, educators, and technical service providers from across the country.

The work conducted over the past ten years by the Vermont Bioenergy Initiative to conduct research, provide technical assistance, and develop infrastructure in emerging areas of bioenergy will continue with the initiative’s partners at UVM Extension and the Vermont Agency of Agriculture, Food & Markets. As Vermont moves forward – being innovative and increasingly focused on generating renewable energy from the land and forests – the research and infrastructure the Vermont Bioenergy Initiative has invested in over the past ten years will endure and spawn the next wave of bioenergy development in the state.

Ellen Kahler is executive director of the Vermont Sustainable Jobs Fund (VSJF), a non-profit organization created by the State of Vermont to help develop Vermont’s sustainable agriculture, renewable energy, and forest product businesses. Since 2005, the Vermont Bioenergy Initiative has been a VSJF program that connects diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. Learn more at www.VermontBioenergy.com.

Making Biofuel

Monday, July 13, 2015 Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Can Consumers Grow Sunflower Crops for Biodiesel?

Thursday, November 13, 2014Farmers in Vermont are making their own biodiesel from sunflowers, and maybe you have wondered: Can I do that?

First, you might be interested to watch this video on growing sunflowers for biodiesel:

You may be interested in increasing self-sufficiency, replacing fossil fuel with a renewable or saving $2.00 per gallon on diesel fuel. But can the average landowner grow their biodiesel?

Land is the first thing needed to grow sunflowers. But most homesteaders or homeowners are not likely to have the equipment required for producing their own biodiesel, like a combine for harvesting the sunflowers, an oilseed press for extracting oil and a processor for converting the oil to biodiesel. These are expensive pieces of equipment that require a good deal of know-how, and the payback just isn’t there for the small-time producer.

Processing can be done, however, at some on-farm facilities, including Borderview Research Farm in Alburgh, State Line Biofuel Farm in North Bennington and other private farms, or in conjunction with other farms growing oilseeds like Woods Market Garden in Brandon and Ekolott Farm in Newbury. Growers located near to these farms could consider growing oilseeds on their land and bringing them to a nearby facility for processing into biodiesel.

Those wishing to purchase locally-grown biodiesel can also look to Full Sun Company in Middlebury, who will be providing to consumers biodiesel fuel made from recycled cooking oil produced at their Vermont mill and made from locally-grown oilseeds like soybeans, canola and sunflowers.

For growers that do have the land available for oilseed production and a place to process their seed, the growing manual “Oilseed Production in the Northeast” by Dr. Heather Darby at University of Vermont Extension is a useful resource. Those considering the economics of this endeavor should download the “Oilseed Cost and Profit Calculator” produced by Chris Callahan PE at UVM Extension. For more resources including videos, image galleries, reports and helpful links, click to learn more about growing oilseeds for biofuel.