14 Sep 2015

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

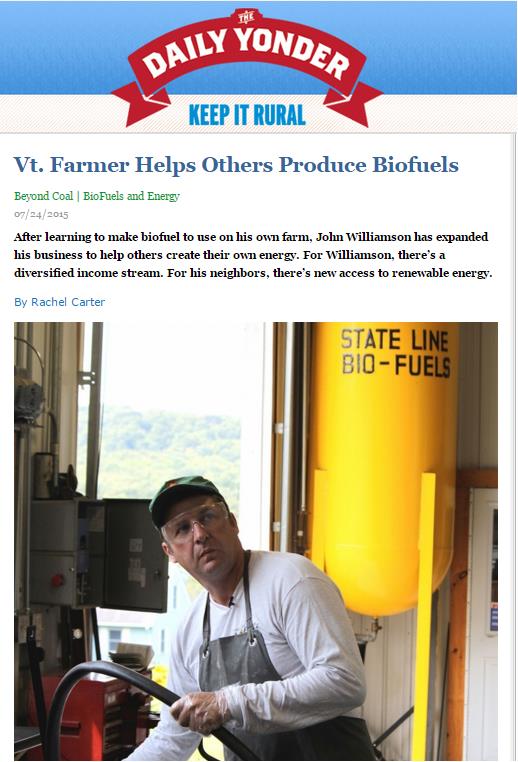

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

In early 2014 Full Sun Company, a small start-up business was co-founded by Netaka White and Davis McManus. Fueled by an interest to help family farms grow, Full Sun began processing sunflower and non-GMO canola oil crops into specialty food-grade oil and high-protein meal for the farmers. Sunflower and canola oil distribution picked up quickly through local CSAs, farm stores, specialty food shops, health and wellness centers, and direct sales to chefs in the Northeast.

Netaka White previously served as the Vermont Bioenergy Initiative’s (VBI) program director, which directly helped to develop the business model to nurture farm partnerships, both as growers and recipients of oilseed meal – the other product that’s generated from making the oil. At Full Sun oilseeds are pressed with large mechanical machinery, producing oil and a granular meal. The team at Full Sun Company learned a lot about seed storage and oil pressing from the early VBI grantees, such as John Williamson of State Line Farm, and Roger Rainville of Borderview Farm.

The first of the two products, the seed meal, has been used as fuel for pellet stoves, or as is the case with Full Sun, sold as fertilizer for crops, or nutritional meal for livestock. At full operation, Full Sun can pump out one ton of meal per day – necessary to meet the growing demand of such customers as The Intervale in Burlington, Vermont and several local pig, poultry, dairy, and beef producers.

Full Sun Company employee, Zach Hartlyn, moves an off-spec oil barrel for biodiesel production

Credit: Full Sun Company

The second product, the oil, is used as culinary oil for cooking. Staying true to their commitment to an extraordinary culinary product, Full Sun Company diverts any of the oil that does not meet their standards to Vermont Bioenergy Initiative biofuel producers to undergo further processing and become biofuel. Approximately 250-300 gallons of off-spec oil for biodiesel has been processed since February, 2014.

In October, 2014, Full Sun Company halted operation to make room for growth to meet the increased demand for their products and scale up to align with Vermont’s accelerating agricultural economy. White and McManus acquired the former Vermont Soap building in Middlebury, Vermont in order to build a full scale mill and achieve their anticipated greater capacity. Over the course of one of the coldest winters in recent history, the Full Sun team made the renovations and adjustments needed to repurpose the building into the first non-GMO verified oil mill in New England. By March of 2015 Full Sun Company had pressed sunflower and canola seeds to make their first batch of specialty oils. The new operation can yield 130 gallons of oil per day – about 2600 gallons per month!

With no shortage of innovation or ambition, White notes, “David and I are in this with the interest of having a transformative effect on local agriculture and food systems.” Well on their way, the operation is certified GMO free, and the next steps are being taken towards becoming certified organic.

As they grow, Full Sun would like to buy from local grower-suppliers and work with local businesses to package and label feed to be distributed to farmers of varying sizes, from backyard chicken growers to larger operations. Collaborating with Vermont breweries and distilleries is also in queue. Full Sun is working with one local distillery to put together “a package” for farmers so they have markets for profitable grain crops throughout four years of rotation (rye, wheat, sunflowers, etc.) and can offer farmers the indexed prices for these locally grown grains and oilseeds.

19 Sep 2013

Ekolott Farm

Feedstock: Sunflowers, soybeans and canola

Feedstock: Sunflowers, soybeans and canola

Fuel: Biodiesel

Co-products: High-protein sunflower meal as feed ingredient

Energy Output: Power (for farm machinery) and heat (for farmhouse)

Services: Oilseed Grower, Oil milling, Feed Supply

Owner: Larry Scott and Peggy Hewes

Location: Newbury, Vermont

Larry Scott and Peggy Hewes operate Ekolott Farm—a diversified farm raising emus, Herefords, and hogs, and growing feed and energy crops such as shell corn, sunflowers, and soybeans on 200 acres of Connecticut River valley land. Ekolott produces biodiesel to fuel a portion of their tractor work, all of their own heat and an increasing amount of the feed ingredients for their animals, including grains and sunflower seed meal.

Ekolott is a three-generation dairy farm that moved to Vermont from Massachusetts in 1980. The farm consistently achieved Vermont milk quality awards with their 220 registered Holsteins, until the cows were sold in 2004.

Diversification of the farm had already begun in 1994 when the Scott family began raising emus (they are currently the largest and one of the oldest emu farms in Vermont, under the name Riverside Emus). With barns and pasture freed up after the dairy herd was sold, the Scott-Hewes took on raising Herefords and hogs and have been developing a local customer base for their beef, pork, and emu through on-farm and farmers’ market sales.

Read More

19 Sep 2013

Borderview Research Farm

Feedstock: Sunflowers, canola, switchgrass

Fuel: Biodiesel and grass pellets

Energy Output: Power (for farm machinery) and heat

Services: Oilseed and Grain Grower, Oil milling, Biomass Pelletizing, Fuel Processing, Feed Supply

Owner: Roger and Claire Rainville

Location: Alburgh, Vermont; Grand Isle County

Having sold his dairy herd several years ago and thinking he was heading into semi-retirement, Roger Rainville began experimenting with farm-scale biodiesel production on his family farm in northern Vermont, which literally hugs the Canadian border.

The University of Vermont (UVM) now leases a number of acres from the Rainvilles as Borderview Farm has become one of the best-known applied research facilities in Vermont. Roger, along with Dr. Heather Darby, a UVM Extension agronomist, and her team have helped transform the former dairy farm, conducting leading research in the Northeast on oilseed crops, perennial grasses, hops, small grains and other crops suitable for small-scale and value-added farming.