14 Sep 2015

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

In early 2014 Full Sun Company, a small start-up business was co-founded by Netaka White and Davis McManus. Fueled by an interest to help family farms grow, Full Sun began processing sunflower and non-GMO canola oil crops into specialty food-grade oil and high-protein meal for the farmers. Sunflower and canola oil distribution picked up quickly through local CSAs, farm stores, specialty food shops, health and wellness centers, and direct sales to chefs in the Northeast.

Netaka White previously served as the Vermont Bioenergy Initiative’s (VBI) program director, which directly helped to develop the business model to nurture farm partnerships, both as growers and recipients of oilseed meal – the other product that’s generated from making the oil. At Full Sun oilseeds are pressed with large mechanical machinery, producing oil and a granular meal. The team at Full Sun Company learned a lot about seed storage and oil pressing from the early VBI grantees, such as John Williamson of State Line Farm, and Roger Rainville of Borderview Farm.

The first of the two products, the seed meal, has been used as fuel for pellet stoves, or as is the case with Full Sun, sold as fertilizer for crops, or nutritional meal for livestock. At full operation, Full Sun can pump out one ton of meal per day – necessary to meet the growing demand of such customers as The Intervale in Burlington, Vermont and several local pig, poultry, dairy, and beef producers.

Full Sun Company employee, Zach Hartlyn, moves an off-spec oil barrel for biodiesel production

Credit: Full Sun Company

The second product, the oil, is used as culinary oil for cooking. Staying true to their commitment to an extraordinary culinary product, Full Sun Company diverts any of the oil that does not meet their standards to Vermont Bioenergy Initiative biofuel producers to undergo further processing and become biofuel. Approximately 250-300 gallons of off-spec oil for biodiesel has been processed since February, 2014.

In October, 2014, Full Sun Company halted operation to make room for growth to meet the increased demand for their products and scale up to align with Vermont’s accelerating agricultural economy. White and McManus acquired the former Vermont Soap building in Middlebury, Vermont in order to build a full scale mill and achieve their anticipated greater capacity. Over the course of one of the coldest winters in recent history, the Full Sun team made the renovations and adjustments needed to repurpose the building into the first non-GMO verified oil mill in New England. By March of 2015 Full Sun Company had pressed sunflower and canola seeds to make their first batch of specialty oils. The new operation can yield 130 gallons of oil per day – about 2600 gallons per month!

With no shortage of innovation or ambition, White notes, “David and I are in this with the interest of having a transformative effect on local agriculture and food systems.” Well on their way, the operation is certified GMO free, and the next steps are being taken towards becoming certified organic.

As they grow, Full Sun would like to buy from local grower-suppliers and work with local businesses to package and label feed to be distributed to farmers of varying sizes, from backyard chicken growers to larger operations. Collaborating with Vermont breweries and distilleries is also in queue. Full Sun is working with one local distillery to put together “a package” for farmers so they have markets for profitable grain crops throughout four years of rotation (rye, wheat, sunflowers, etc.) and can offer farmers the indexed prices for these locally grown grains and oilseeds.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

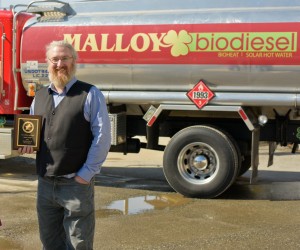

Jim Malloy, of Plainfield, Vermont, is recognized for displacing petroleum with biodiesel in New England’s transportation sector.

Jim Malloy, of Plainfield, Vermont, is being recognized for his contributions to reducing the use of petroleum fuel in the transportation sector. His business, TH Malloy and Sons in Newport, Rhode Island, is being recognized with the New England Northern Star Award as one of the top fleets for reducing their emissions through the use of biodiesel made from recycled restaurant oil.

The 75-year-old family business is a distributor for Newport Biodiesel, also of RI, who produces biodiesel from recycled restaurant oil. Both companies are being recognized with the award.

Each recipient of the award demonstrated a deep commitment to the goals of the Clean Cities program through use of alternative fuels, alternative fuel vehicle purchasing, and petroleum reduction practices. The designation as a Northern Star required that the fleets be a stakeholder in their local Clean Cities Coalitions and that they meet a list of criteria showing their commitment to Clean Cities’ initiatives.

Malloy introduced biodiesel fuel into his RI company’s distribution fleet and has helped 4,000 customers replace oil with biodiesel. His efforts have displaced nearly 4 million gallons of oil in the past seven years. Malloy is also being recognized for the impact he has had on reducing emissions statewide by working in the RI legislature to make biodiesel a more affordable fuel option.

Replacing petroleum fuel with biodiesel that is produced locally from recycled cooking oil has the benefits of increased energy security, stronger local economies, improved air quality, and reduced contributions to global climate change.

“I am honored to be recognized,” says Malloy. “I’m passionate about recycling waste and creating an outlet for less expensive and cleaner-burning domestically-made fuel that displaces petroleum.”

Malloy is also owner of Black Bear Biodiesel in Plainfield, Vermont, which is a two-year-old restaurant oil collection recycling service and biodiesel distributor serving northern and central Vermont. The company plans to have drive-up fill-up stations at their Plainfield location in late May.

“I look forward to bringing this same passion for recycling and emissions reduction and petroleum displacement to Vermont as well, while at the same time saving locals money by providing a more efficient, cleaner fuel and an affordable replacement for petroleum,” says Malloy.

The other four recipients of the award are the City of Boston Massachusetts, the City of Nashua New Hampshire, Oakhurst Dairy in Maine and New Hampshire, and the University of Vermont.

The Northern Stars of New England program

was funded through a U.S. Department of Energy grant that identified barriers to the proliferation of alternative fuels and how to remove them. There are nearly one hundred Clean Cities Coalitions around the country whose purpose is to help reduce the use of petroleum, cut emissions, and promote alternative fuel options. The Northern Stars program was developed by the five Northern New England Clean Cities Coalitions and is just one of the ways that these coalitions promote the use of alternative fuels in fleets.

This project is funded by a U.S. Department of Energy grant awarded to Maine Clean Communities, a program of the Greater Portland Council of Governments (GPCOG), and other Northern New England Clean Cities Coalition grant partners.

More information on the Northern Stars program can be found on the Vermont Clean Cities Coalition website at www.uvm.edu/vtccc.

06 Apr 2015

Upcoming North American Bioenergy Events

Make sure to check on the Vermont Bioenergy Initiative website for more national bioenergy events as we will be updating this list!

- May

- June

- WasteExpo 2015 June 1-5, 2015 Las Vegas Convention Center

- 5th International Conference on Algal Biomass, Biofuels and Bioproducts. 7 – 10 June 2015. San Diego, USA

- BIO International Convention June 15-18, 2015. Philadelphia, PA

- Bioenergy 2015,June 23-25. Washington, DC

- GAI AgTech Week June 22-24, 2015 San Francisco, CA

- July

- 19th Annual Green Chemistry & Engineering Conference (GC&E). July 14-16, 2015. N. Bethesda, MD

- BIO World Congress on Industrial Biotechnology. July 19 – 22, 2015. Montreal, Canada

- EnergyPath 2015, July 20-24. Scranton, PA

- BioFuelNet Advanced Biofuels Symposium 2015. July 22 – 24, 2015. Montreal, Canada

- August

- September

- Switchgrass III. September 30 to October 2, 2015. Knoxville, TN

- 2nd International Conference on Past and Present Research Systems of Green Chemistry. September 14-16, 2015. Orlando, Florida

- Ag Innovation Showcase September 14-16, 2015 St. Louis, MO

- Algae Biomass Summit September 30-October 2, 2015 Washington, DC

- October

- November

Farmers in Vermont are making their own biodiesel from sunflowers, and maybe you have wondered: Can I do that?

First, you might be interested to watch this video on growing sunflowers for biodiesel:

You may be interested in increasing self-sufficiency, replacing fossil fuel with a renewable or saving $2.00 per gallon on diesel fuel. But can the average landowner grow their biodiesel?

Land is the first thing needed to grow sunflowers. But most homesteaders or homeowners are not likely to have the equipment required for producing their own biodiesel, like a combine for harvesting the sunflowers, an oilseed press for extracting oil and a processor for converting the oil to biodiesel. These are expensive pieces of equipment that require a good deal of know-how, and the payback just isn’t there for the small-time producer.

Processing can be done, however, at some on-farm facilities, including Borderview Research Farm in Alburgh, State Line Biofuel Farm in North Bennington and other private farms, or in conjunction with other farms growing oilseeds like Woods Market Garden in Brandon and Ekolott Farm in Newbury. Growers located near to these farms could consider growing oilseeds on their land and bringing them to a nearby facility for processing into biodiesel.

Those wishing to purchase locally-grown biodiesel can also look to Full Sun Company in Middlebury, who will be providing to consumers biodiesel fuel made from recycled cooking oil produced at their Vermont mill and made from locally-grown oilseeds like soybeans, canola and sunflowers.

For growers that do have the land available for oilseed production and a place to process their seed, the growing manual “Oilseed Production in the Northeast” by Dr. Heather Darby at University of Vermont Extension is a useful resource. Those considering the economics of this endeavor should download the “Oilseed Cost and Profit Calculator” produced by Chris Callahan PE at UVM Extension. For more resources including videos, image galleries, reports and helpful links, click to learn more about growing oilseeds for biofuel.

Beautiful fields of sunflowers growing in Newbury and Shaftsbury, Vermont will have an unusual future: the flowers’ seeds will be converted to biodiesel and livestock feed. The fuel will be used in Green Mountain Power’s fleet of vehicles and for building heating, saving Green Mountain Power customers money and reducing greenhouse gas emissions and other pollutants. The feed will be used on Vermont farms to supplement animal nutrition.

“Green Mountain Power is leading the way in many local energy initiatives,” said Green Mountain Power President and CEO Mary Powell. “Using Vermont sunflowers to power our vehicles and heat our buildings is a beautiful way to keep our energy local and clean.”

Twenty acres of sunflowers are growing at the State Line Farm Biofuels in Shaftsbury and another ten acres are growing at the Ekolott Farm in Newbury. When the oilseeds are harvested this fall, they will be dried and pressed, then the raw oil will be converted to biodiesel, or B100. The solid portion of the seed, the meal, is valuable as a livestock feed. Depending on the crops’ success, the cost of fuel to Green Mountain Power could be up to one dollar less than current B100 prices.

Sunflowers being harvested at State Line Biofuel Farm in Shaftsbury VT

“It is so great to be part of this innovative test with GMP,” said John Williamson of State Line Farm Biofuels. “Projects like this really help support farmers, plus it’s beautiful to see the fields of sunflowers and even more beautiful to realize it will provide a clean and local power source.”

This pilot is a partnership between Green Mountain Power, UVM Extension, and the Vermont Bioenergy Initiative. UVM Extension and the Vermont Bioenergy Initiative have worked together for several years to encourage the growth of oil seeds as an energy source and the addition of Green Mountain Power is hoped to accelerate this effort even further.

“As a result of the Vermont Bioenergy Initiative, several pioneering farmers in Vermont now have the necessary infrastructure to produce sustainable biodiesel,” notes Chris Callahan, UVM Extension Agricultural Engineer. “This is a unique model: local production for local use. The partnership with Green Mountain Power means more gallons will be made which means lower cost for everyone.”

“The goal is for local biodiesel production to both shave fuel costs for our customers while helping to develop new markets for locally produced liquid fuels,” said Powell. “We see this benefiting local farms and customers as we work together to provide more clean cost-effective and reliable power.”

###

About Green Mountain Power

Green Mountain Power (GMP) serves approximately 265,000 residential and business customers in Vermont and has a vision to be the best small company in America by empowering customers to save money and move to clean energy sources. GMP recognizes the role of electric utilities is changing and is focused on a new way of doing business to meet the needs of customers with integrated services, while continuing to generate clean, cost-effective and reliable power in Vermont. In 2014, Vote Solar named GMP a Solar Champion. More information at: www.greenmountainpower.com.

About the Vermont Bioenergy Initiative

A program of the Vermont Sustainable Jobs Fund, the Vermont Bioenergy Initiative connects diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. More information at: www.VermontBioenergy.com.