With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

Algae produces more than half of the oxygen on the planet, while consuming vast amounts of heat-trapping carbon dioxide and taking up nutrients like nitrogen and phosphorous to make biomass and energy. The lipids, or oil, that algae produce can be extracted and processed into renewable fuels such as biodiesel. Algae are an excellent source of oil for making biodiesel, which could displace substantial volumes of petro-diesel for heating and transportation. Microalgae reproduce rapidly, and they grow on non-agricultural land, so they do not compete with food, feed, or fiber production.

The keys to commercializing algae for biofuel production include identifying and cultivating native species, optimizing growing conditions in natural and artificial environments and the efficient harvest and oil extraction of algal biomass. At the forefront of this algae biofuel research is Dr. Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. Dr. Dahiya has been searching for high lipid algae strains, and scaling those up to a level that could be available for commercial use, especially for biofuels.

“At GSR Solutions, we are looking at producing algae not just for biofuels, but combining it with waste water treatment and to produce other valued byproducts as well. This is very significant, because this would make algae production cost-effective. This would also help in nutrient recovery,” says Dahiya.

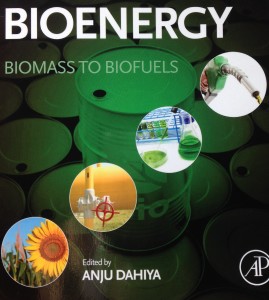

innovative new textbook that provides insight into the potential and current advances and benefits of biofuel

Some of the findings and knowledge afforded by Dr. Dahiya’s research are available in the new introductory textbook, Bioenergy: Biomass to Biofuels, which was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories. Dr. Dahiya will also be using this textbook as the basis for a University of Vermont Bioenergy Course offered for the 2015 fall semester.

In the below video, Vermont researchers and entrepreneurs demonstrate their innovations in algae to biofuel research and development.

For more algae bioenergy resources see the visit the Algae section of the Vermont Bioenergy Website.

Learn more about the mentioned UVM Bioenergy Course visit the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

For more information on the introductory textbook Bioenery; Biomass to Biofuels see our write up on the book here!

01 Jun 2015

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”

19 May 2015

Mitigating Potential Biomass Feedstock Pests

The Vermont Bioenergy Initiative aims to connect diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution. As we move into the growing season, there are a variety of pests that can potentially affect sunflower, canola, and soybean biomass feedstock production. In this video a University of Vermont agronomist explains how to control theses potential biomass feedstock pests and increase crop, and eventually biofuel, yields without heavy reliance on pesticides and herbicides.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The database was originally created with funding from the U.S. Endowment for Forestry and Communities and further improvements were made with funding from the U.S. Department of Energy through the support of Vermont Senator Patrick Leahy. The re-tooled database is a user-friendly, interactive tool that will help collect and track information on a continuing basis. “This resource will provide stakeholders from a variety of backgrounds with a better understanding of the current demand for wood fuels as an energy source and the success of modern wood heating projects throughout North America,” said Adam Sherman, Manager of BERC at VEIC.

The database already contains more than 500 entries, but to ensure that this publicly available resource is accurate and up to date, BERC is asking for user participation. “We are committed to maintaining and building this database over time to ensure it remains a useful and reliable too, but this is a rapidly growing sector, so we need users to help,” said Sherman. “We need people to engage with the database; add new entries for facilities that have been missed and as new facilities come online, and edit existing entries that are incomplete.” With regular contributions, the database will continue to improve and grow.

With tens of thousands of annual visits and top Google search ranking, the BERC website is a high-visibility home for this important tool. The BERC database is designed to provide vital information on a specific subset of biomass energy facilities; community-scale biomass heating projects. The BERC database complements the Wood2Energy.org database that covers a broader spectrum of biomass energy facilities including power plants, sawmills, and pellet mills. Not only will the BERC database provide wood heating systems vendors the exposure and recognition for their projects, it also helps demonstrate that modern wood heating is becoming mainstream throughout North America. To learn more about using and contributing to the database visit www.biomasscenter.org/database.

About BERC

The Biomass Energy Resource Center (BERC) is a program of Vermont Energy Investment Corporation (VEIC). BERC works to advance the use of community-scale biomass energy throughout North America and beyond by providing technical consulting services, biomass energy program design and delivery, and education and outreach on benefits and best practices. BERC works with communities, federal, state and local governments, colleges and universities, businesses, utilities, and others to use local biomass resources, invest in local energy systems, and reduce the use of fossil heating fuels.

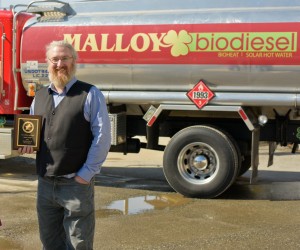

Jim Malloy, of Plainfield, Vermont, is recognized for displacing petroleum with biodiesel in New England’s transportation sector.

Jim Malloy, of Plainfield, Vermont, is being recognized for his contributions to reducing the use of petroleum fuel in the transportation sector. His business, TH Malloy and Sons in Newport, Rhode Island, is being recognized with the New England Northern Star Award as one of the top fleets for reducing their emissions through the use of biodiesel made from recycled restaurant oil.

The 75-year-old family business is a distributor for Newport Biodiesel, also of RI, who produces biodiesel from recycled restaurant oil. Both companies are being recognized with the award.

Each recipient of the award demonstrated a deep commitment to the goals of the Clean Cities program through use of alternative fuels, alternative fuel vehicle purchasing, and petroleum reduction practices. The designation as a Northern Star required that the fleets be a stakeholder in their local Clean Cities Coalitions and that they meet a list of criteria showing their commitment to Clean Cities’ initiatives.

Malloy introduced biodiesel fuel into his RI company’s distribution fleet and has helped 4,000 customers replace oil with biodiesel. His efforts have displaced nearly 4 million gallons of oil in the past seven years. Malloy is also being recognized for the impact he has had on reducing emissions statewide by working in the RI legislature to make biodiesel a more affordable fuel option.

Replacing petroleum fuel with biodiesel that is produced locally from recycled cooking oil has the benefits of increased energy security, stronger local economies, improved air quality, and reduced contributions to global climate change.

“I am honored to be recognized,” says Malloy. “I’m passionate about recycling waste and creating an outlet for less expensive and cleaner-burning domestically-made fuel that displaces petroleum.”

Malloy is also owner of Black Bear Biodiesel in Plainfield, Vermont, which is a two-year-old restaurant oil collection recycling service and biodiesel distributor serving northern and central Vermont. The company plans to have drive-up fill-up stations at their Plainfield location in late May.

“I look forward to bringing this same passion for recycling and emissions reduction and petroleum displacement to Vermont as well, while at the same time saving locals money by providing a more efficient, cleaner fuel and an affordable replacement for petroleum,” says Malloy.

The other four recipients of the award are the City of Boston Massachusetts, the City of Nashua New Hampshire, Oakhurst Dairy in Maine and New Hampshire, and the University of Vermont.

The Northern Stars of New England program

was funded through a U.S. Department of Energy grant that identified barriers to the proliferation of alternative fuels and how to remove them. There are nearly one hundred Clean Cities Coalitions around the country whose purpose is to help reduce the use of petroleum, cut emissions, and promote alternative fuel options. The Northern Stars program was developed by the five Northern New England Clean Cities Coalitions and is just one of the ways that these coalitions promote the use of alternative fuels in fleets.

This project is funded by a U.S. Department of Energy grant awarded to Maine Clean Communities, a program of the Greater Portland Council of Governments (GPCOG), and other Northern New England Clean Cities Coalition grant partners.

More information on the Northern Stars program can be found on the Vermont Clean Cities Coalition website at www.uvm.edu/vtccc.

06 Apr 2015

Upcoming North American Bioenergy Events

Make sure to check on the Vermont Bioenergy Initiative website for more national bioenergy events as we will be updating this list!

- May

- June

- WasteExpo 2015 June 1-5, 2015 Las Vegas Convention Center

- 5th International Conference on Algal Biomass, Biofuels and Bioproducts. 7 – 10 June 2015. San Diego, USA

- BIO International Convention June 15-18, 2015. Philadelphia, PA

- Bioenergy 2015,June 23-25. Washington, DC

- GAI AgTech Week June 22-24, 2015 San Francisco, CA

- July

- 19th Annual Green Chemistry & Engineering Conference (GC&E). July 14-16, 2015. N. Bethesda, MD

- BIO World Congress on Industrial Biotechnology. July 19 – 22, 2015. Montreal, Canada

- EnergyPath 2015, July 20-24. Scranton, PA

- BioFuelNet Advanced Biofuels Symposium 2015. July 22 – 24, 2015. Montreal, Canada

- August

- September

- Switchgrass III. September 30 to October 2, 2015. Knoxville, TN

- 2nd International Conference on Past and Present Research Systems of Green Chemistry. September 14-16, 2015. Orlando, Florida

- Ag Innovation Showcase September 14-16, 2015 St. Louis, MO

- Algae Biomass Summit September 30-October 2, 2015 Washington, DC

- October

- November

Nick Meyer of North Hardwick Dairy, an Organic Valley milk producer, was able to reduce energy costs and increase self-sufficiency by growing sunflowers for biodiesel and meal while maintaining a wind turbine to help cover electricity needs.

We all know food gives us energy. But we might sometimes lose sight of the amount of energy involved in producing, processing and delivering that food to our plates. Everything requires energy: from tractors plowing and planting to producing fertilizer or compost; from milking cows and keeping that milk cold to storing and transporting vegetables. This energy costs farms real money and it is sometimes a major category of expense. Energy costs are typically one of the highest for farms, rivaling feed costs on dairy farms and labor costs on vegetable farms.

As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more and more important. This has been part of Vermont’s Farm to Plate Strategic Plan and the associated network of people working on implementing that plan. The plan includes goals related to energy, including; reducing farm production expenses, reducing adverse environmental impacts from farm and food system activities, reducing energy use, and increasing renewable energy use in the food system.

One example of how this is actually working is a group called the Farm to Plate Energy Cross Cutting Team: a group of energy specialists from Efficiency Vermont, the Agency of Agriculture, UVM’s Rubenstein School and UVM Extension, The Vermont Bioenergy Initiative, USDA NRCS and private companies. The team meets regularly to learn from each other and take on specific projects such as the recent set of seven “Energy Success Stories” which were released at the 2014 Farm Show, showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production.

Chaired by Efficiency Vermont planning manager, JJ Vandette, the energy team will continue to address the Farm to Plate Efficiency and Renewable Energy Goal to decrease overall food system energy consumption and increase food system renewable energy production and the Farm to Plate Environmental Impacts Goal to decrease adverse environmental impacts from farming and food system activities—while helping to decrease production expenses—also a goal of the Farm to Plate Strategic Plan.

The team is always interested in having new members. If you have an interest in energy, especially energy on farms and in the food system, we’d love to hear from you. JJ Vandette can be reached at jvandette@veic.org or 802.540.7915.

Data sources and analysis at www.vtfarmtoplate.com/getting-to-2020.

2014 was a busy year for the Vermont Bioenergy Initiative as we engaged in national outreach efforts to share our work connecting diversified agriculture and local renewable energy production for on-farm and community use in ways that be applicable to rural areas around the country. These rural areas are often at “the end of the pipeline” and are subject to higher and more volatile costs for energy. The Vermont Bioenergy Initiative “local production for local use” model shows that rural communities can produce some of their own energy, thereby improving their energy security and benefitting from more predictable and affordable energy prices. Any farm in any part of the country can grow and process their own fuel, using the best practices developed by the collaborating farms and UVM Extension researchers working in partnership with the Vermont Bioenergy Initiative. Funding for our program work to support research, technical assistance, and infrastructure development in emerging areas of bioenergy was secured by US Senator Patrick Leahy and the US Department of Energy.

Recent news we distributed to local, regional, and national audiences includes:

Local production for local use is biofuel model that works in Vermont.

Vermont sunflowers to help provide biodiesel power.

We have worked with several regional and national publications to secure editorial specifically featuring oil crops for on-farm biodiesel and feed, and grass energy for heating.

Check out the recent interview with our UVM Extension consultant and agricultural engineer, Chris Callahan in Biofuels Journal.

Read about alternative energy innovations on the farm featuring farms a part of the Farm Fresh Fuel Project in Farming Magazine.

The Grass Energy Report we released summer 2014 was featured extensively in both Renewable Energy World and On Pasture Magazine.

Visit the Green Energy Times website for our ongoing column, Emerging Frontiers in Bioenergy and follow the Vermont Bionenergy on Twitter for current news, trends, and tweets on renewable energy in Vermont and beyond.

- February

- Biomass Boot Camp, February 23, Catonsville, MD

- Farm Energy IQ – Training for NE Ag Service Providers in VT February 23- 25, Fairlee, VT

- ACI’s 4th Carbon Dioxide Utilization Conference 2015 February 25-26 San Antonio, TX

- 2015 Executive Leadership Conference. 25 February – 1 March 2015. Phoenix, Arizona

- March

- World Agri-Tech Investment Summit. March 3-4, 2015 San Francisco, CA

- Waste to Biogas and Clean Fuels Finance and Investment Summit. March 3-4 San Jose, CA

- Farm Energy IQ – Training for NE Ag Service Providers March 10-12, 2015 State College, PA

- Advanced Bioeconomy Leadership Conference March 11-15, 2015 Washington, DC

- Next-Generation Defense Energy Symposium. 17 – 18 March, 2015. Washington, United States

- WEBINAR: Using B100 in Our Class-8 Trucking Operations (60 trucks) in Tennessee March 19, 2015 10:00 AM ET

- ACI’s Annual Lignofuels Americas Summit March 25-26, 2015 Milwaukee, WI

- Forest Products and Timberland Investment Conference. March 31-April 1, 2015. New York, NY

- April

- Applying Renewable Energy – Online Training April 01, 2015 at 09:00 AM to June 30, 2015 at 06:00 PM

- Farm Energy IQ – Training for NE Ag Service Providers in NJ, April 8- 10, Bordentown, NJ

- 5th Defense Renewable Energy Summit. 7-8 April 2015. Arlington, VA

- Good Jobs, Green Jobs 2015 April 13 Washington, D.C

- 2015 Northeast Biomass Heating Expo. April 16-18, 2015. Portland, ME

- Introduction to Renewable Energy Technologies Start date: 20 to 22, 2015

- International Biomass Conference and Expo. 20 -22 April 2015. Minneapolis, MN

- 37th Symposium on Biotechnology for Fuels and Chemicals. April 27 – 30, 2015 San Diego, CA