UVM Extension and the Vermont Bioenergy Initiative supported the installation of a multi-source biomass fuel boiler at the Vermont Farmers Food Center in Rutland, Vermont. The boiler uses several alternative fuels, such as wood pellets and grass biomass pucks, to displace propane and heat the 4,200 square foot space, home to the Rutland Winter Farmers’ Market and a variety of food system educational program and events. The biomass project demonstrates the economic advantages when compared to typical propane heaters, including a much smaller payback period (roughly 2-8 years) when using biomass fuel sources. Chris Callahan, a UVM Extension Agricultural Engineer, directed the project and worked closely with the Vermont Farmers Food Center to fit a biomass fuel boiler for the space specifications.

UVM Extension and the Vermont Bioenergy Initiative supported the installation of a multi-source biomass fuel boiler at the Vermont Farmers Food Center in Rutland, Vermont. The boiler uses several alternative fuels, such as wood pellets and grass biomass pucks, to displace propane and heat the 4,200 square foot space, home to the Rutland Winter Farmers’ Market and a variety of food system educational program and events. The biomass project demonstrates the economic advantages when compared to typical propane heaters, including a much smaller payback period (roughly 2-8 years) when using biomass fuel sources. Chris Callahan, a UVM Extension Agricultural Engineer, directed the project and worked closely with the Vermont Farmers Food Center to fit a biomass fuel boiler for the space specifications.

Check out this video featuring the project on Across the Fence, the longest-running locally-produced program in the US:

19 Oct 2015

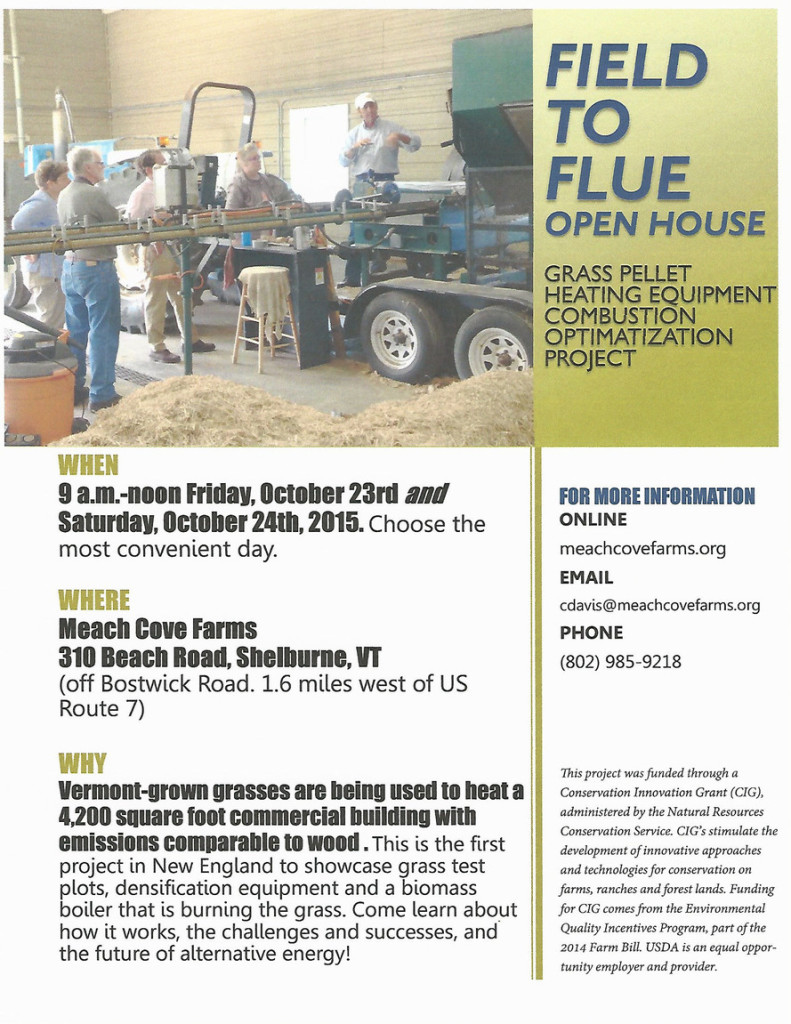

Field to Flue Open House at Meach Cove Farms

Vermont-grown grasses are being used to heat the Biomass Building – a 4,200 square foot commercial building at Meach Cove Farms in Shelburne. Local residents, community leaders, and renewable energy enthusiasts are invited to visit Meach Cove Farms Friday, October 23 – Saturday, October 24 for an Open House to learn how grass pellets are generating heat in a biomass boiler – an emerging source of bioenergy in Vermont.

Meach Cove Farms is a 1,000-acre certified organic farm primarily growing soy beans, wheat, rye, and corn as well as wine grapes, woodlands, and switchgrass trial plots for use in grass energy production. The Open House will offer a complete demonstration of the Grass Pellet Heating Equipment Combustion Optimization project – the first project in New England to showcase grass test plots, densification equipment, and an EvoWorld biomass boiler that burns the grass.

Meach Cove Farms began collaborating with Dr. Sidney Bosworth of the University of Vermont College of Agriculture and Life Sciences and the Vermont Bioenergy Initiative in 2009 to assess the potential of different species of grass as solid biofuel for heating applications.

In September 2011 Meach Cove Farms was awarded an USDA Natural Resources Conservation Service Conservation Innovation Grant to research the feasibility of Vermont grown grass pellets and heating equipment potential as an emerging renewable energy source in Vermont. The biomass boiler being featured at the Open House was funded through a Conservation Innovation Grant (CIG) administered by the Natural Resources Conservation Services.

IF YOU GO:

Meach Cove Farms is located at 310 Beach Road in Shelburne (off Bostwick Road, 1.6 miles west of Rte 7). The Open House runs from 9 am – 12 noon both Friday and Saturday, October 23-24. There is no cost and both days are open to the public. More info at www.meachcovefarms.org, 802-985-9218.

17 Aug 2015

The Third Annual National Bioenergy Day

The T hird Annual National Bioenergy Day (NBD), which will take place Wednesday, October 21st, is a day that is marked with events from across the country that celebrates energy independence, local jobs, and many other benefits of local bioenergy. Led by Biomass Power Association in partnership with U.S. Forest Service, National Bioenergy Day is an opportunity for Vermonters to showcase our research, progress, and impacts in producing local bioenergy for local use.

hird Annual National Bioenergy Day (NBD), which will take place Wednesday, October 21st, is a day that is marked with events from across the country that celebrates energy independence, local jobs, and many other benefits of local bioenergy. Led by Biomass Power Association in partnership with U.S. Forest Service, National Bioenergy Day is an opportunity for Vermonters to showcase our research, progress, and impacts in producing local bioenergy for local use.

How To Get Involved:

- Organize an event on or near October 21ndthat showcases bioenergy as a clean, efficient, and resourceful way to produce energy. Emphasizes bioenergy’s role in improving environmental health; and facilitates collaboration along the supply chain.

- Partner with someone who works in the bioenergy supply chain to create an event. Use the Vermont Energy Atlas to find partners in your area.

- Piggyback on an existing event and call it a NBD event.

- Share and talk about NBD in your social media and press efforts while promoting impacts in your community.

The Vermont Bioenergy Initiative, for example, will spend the day re-capping and previewing events and research on our Twitter handle @VTBioenergy that took place throughout the summer and that are planned for the fall. We’ll be recapping and sharing exciting things like the exciting learning opportunities at the University of Vermont, Full Sun Company’s Biodiesel and Meal production, and much more!

For more information, you can visit also visit bioenergyday.com and follow @USAbiomass on twitter!

Click Here for National Bioenergy Day Participation Guide!

10 Aug 2015

Bioenergy Events 2015

The team  at Vermont Bioenergy Initiative has worked to put together a comprehensive list of bioenergy events for you! This list will be updated as more events arise. If you know a bioenergy events that you think should be on the list, tweet it to us! @VTbioenergy

at Vermont Bioenergy Initiative has worked to put together a comprehensive list of bioenergy events for you! This list will be updated as more events arise. If you know a bioenergy events that you think should be on the list, tweet it to us! @VTbioenergy

- September

- Modern Wood Pellet Heating Forum, Tuesday, Sep. 15, 2015, 6 – 8:30pm, Montshire Museum in Norwich, Vermont

- Ag Innovation Showcase September 14-16, 2015 St. Louis, MO

- 2nd International Conference on Past and Present Research Systems of Green Chemistry. September 14-16, 2015. Orlando, Florida

- Switchgrass III. September 30 to October 2, 2015. Knoxville, TN

- Algae Biomass Summit September 30-October 2, 2015 Washington, DC

- October

- Renewable Energy 2015 Conference & Expo. October 8-9 2015. Burlington, VT

- National Advanced Biofuels Conference & Expo. October 26 – 28, 2015. Omaha, Nebraska

- 2015 TAPPI PEERS Conference – Sustainable Solutions for Our Future. October 25-28, 2015 in Atlanta, Georgia.

- International Bioenergy and Bioproducts Conference 2015 – 10/28 – 10/30 Atlanta, United States

- 3rdAnnual National Bioenergy Day

- November

- April

Farms open their doors to a public interested in learning more about where food comes from and supporting the local agricultural economy

Farmers across Vermont will throw open their barn doors and garden gates to welcome the public for a behind-the-scenes look at Vermont’s vibrant working landscape. Vermont’s first Open Farm Week will be held Monday, August 3 – Sunday, August 9, 2015.

Open Farm Week is a weeklong celebration of Vermont farms. Over 100 farms are participating, many of whom are not usually open to the public. Open Farm Week offers Vermonters and visitors alike educational opportunities to learn more about local food origins, authentic agritourism experiences, and the chance to build relationships with local farmers. Activities vary and may include milking cows and goats, harvesting vegetables, collecting eggs, tasting farm fresh food, scavenger hunts, hayrides, farm dinners, and live music.

Visit DigInVT for a map of participating farms by region. Many events are free and costs vary depending on what activities are offered. Everyone is invited to join the #VTOpenFarm conversations on social media. All participating farms, geographic location, and offerings are at www.DigInVT.com.

Farmers’ markets will also be a part of the Open Farm Week celebration as organizers planned the event to coincide with National Farmers’ Market Week – also the first week of August.

The first Vermont Buy Local Market on the Statehouse Lawn will be held during Open Farm Week on Tuesday, August 4th from 10am-1pm. The Vermont Agency of Agriculture, Food and Markets is organizing the first Statehouse farmers’ market in collaboration with the Capital City Farmers’ Market and NOFA-VT.

Building off of the success of NOFA-VT’s 2014 Open CSA Farm Day, Open Farm Week is a collaborative statewide agritourism project organized by members of the Vermont Farm to Plate Network including Intervale Center, Vermont Farm Tours, Neighboring Food Co-op Association, Vermont Agency of Agriculture, Vermont Fresh Network, Vermont Department of Tourism, Shelburne Farms and Farm-based Education, NOFA-VT, and City Market. Open Farm Week helps Vermont reach its statewide Farm to Plate food system plan goals to increase farm profitability, local food availability, and consumption of Vermont food products.

Vermont Open Farm Week is made possible by the generous support of Premiere Sponsor: City Market/Onion River Coop as well as the Vermont Department of Tourism and Marketing; Vermont Agency of Agriculture, Food and Markets, Localvore Today and Woodchuck Hard Cider.

13 Jul 2015

Making Biofuel

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

29 Jun 2015

Soybeans for On-farm Biodiesel Production

Mark Mordasky, owner of Rainbow Valley Farm in Orwell, Vermont has been growing soybeans as a cash crop and for on-farm biodiesel and animal feed since 2008. When fuel prices began to climb, Mark took initiative and started searching for an innovative and more cost efficient way to meet his farm’s energy demands. The Vermont Sustainable Jobs Fund was able to help Mark take his first steps towards sustainable biofuel production. Mark is able to press these soybeans after harvesting and make two distinct products, oil and meal. The meal is an instantly marketable product and can be sold as feedstock or organic fertilizer; the oil will be further processed into biodiesel.

Soybeans crops are well suited for biodiesel production in Vermont and perform best in heavy soil like those found in Addison County, as University of Vermont Extension Agronomist, Heather Darby explains. Soybeans don’t always do well in in light, well drained soils, and as with any crop the best way to understand the demands of any crops is to contact your University Extension and have your soil tested. Additionally, because soybeans are a legume, they produce nitrogen in association with bacteria, meaning that these crops don’t require the application of additional nitrogen to produce a high yield. These low input, high yield crops are fairly easy to grow, are well suited to the Vermont climate, and afford farmers flexible planting dates. Heather and the rest of the UVM Extension team have seen yields ranging from 35 bushels per acre to up to 85 bushels per acre with varying practices.

In the below video, Mike Mordasky shares his experience and knowledge of soybean production from planting through harvesting harvest and beyond to storage and the creation of the final products. In addition, Heather Darby shares here insights into maturity groupings, variety selection, and best growing practices.

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The database was originally created with funding from the U.S. Endowment for Forestry and Communities and further improvements were made with funding from the U.S. Department of Energy through the support of Vermont Senator Patrick Leahy. The re-tooled database is a user-friendly, interactive tool that will help collect and track information on a continuing basis. “This resource will provide stakeholders from a variety of backgrounds with a better understanding of the current demand for wood fuels as an energy source and the success of modern wood heating projects throughout North America,” said Adam Sherman, Manager of BERC at VEIC.

The database already contains more than 500 entries, but to ensure that this publicly available resource is accurate and up to date, BERC is asking for user participation. “We are committed to maintaining and building this database over time to ensure it remains a useful and reliable too, but this is a rapidly growing sector, so we need users to help,” said Sherman. “We need people to engage with the database; add new entries for facilities that have been missed and as new facilities come online, and edit existing entries that are incomplete.” With regular contributions, the database will continue to improve and grow.

With tens of thousands of annual visits and top Google search ranking, the BERC website is a high-visibility home for this important tool. The BERC database is designed to provide vital information on a specific subset of biomass energy facilities; community-scale biomass heating projects. The BERC database complements the Wood2Energy.org database that covers a broader spectrum of biomass energy facilities including power plants, sawmills, and pellet mills. Not only will the BERC database provide wood heating systems vendors the exposure and recognition for their projects, it also helps demonstrate that modern wood heating is becoming mainstream throughout North America. To learn more about using and contributing to the database visit www.biomasscenter.org/database.

About BERC

The Biomass Energy Resource Center (BERC) is a program of Vermont Energy Investment Corporation (VEIC). BERC works to advance the use of community-scale biomass energy throughout North America and beyond by providing technical consulting services, biomass energy program design and delivery, and education and outreach on benefits and best practices. BERC works with communities, federal, state and local governments, colleges and universities, businesses, utilities, and others to use local biomass resources, invest in local energy systems, and reduce the use of fossil heating fuels.