19 Oct 2015

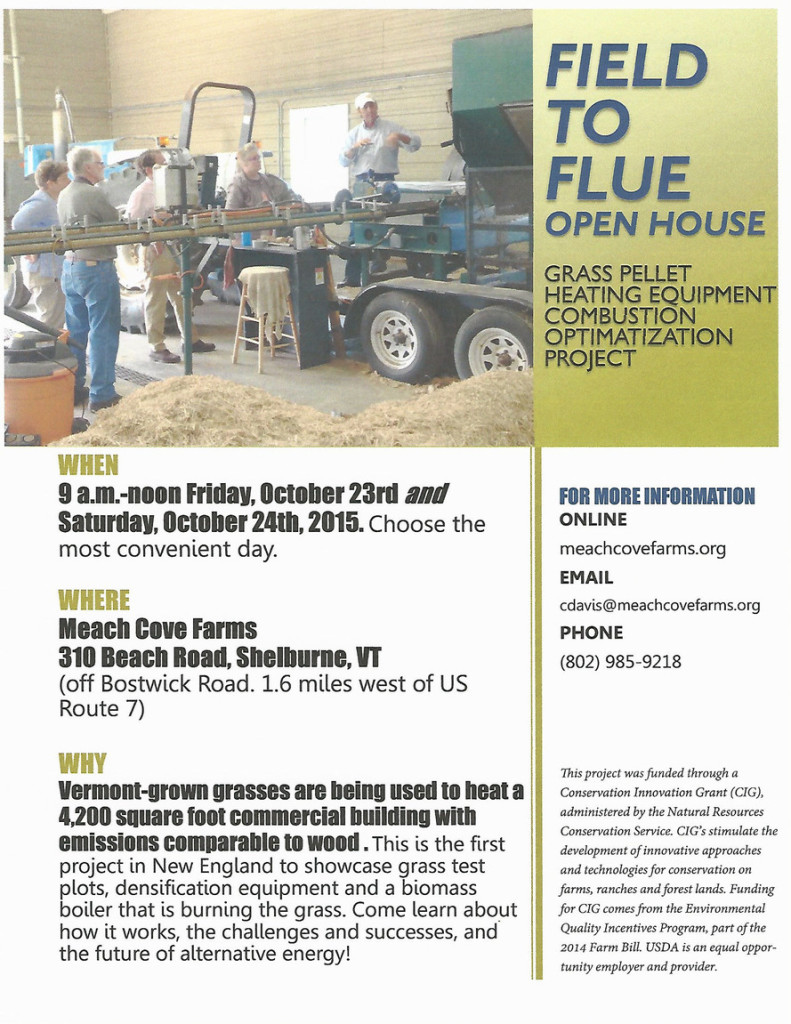

Field to Flue Open House at Meach Cove Farms

Vermont-grown grasses are being used to heat the Biomass Building – a 4,200 square foot commercial building at Meach Cove Farms in Shelburne. Local residents, community leaders, and renewable energy enthusiasts are invited to visit Meach Cove Farms Friday, October 23 – Saturday, October 24 for an Open House to learn how grass pellets are generating heat in a biomass boiler – an emerging source of bioenergy in Vermont.

Meach Cove Farms is a 1,000-acre certified organic farm primarily growing soy beans, wheat, rye, and corn as well as wine grapes, woodlands, and switchgrass trial plots for use in grass energy production. The Open House will offer a complete demonstration of the Grass Pellet Heating Equipment Combustion Optimization project – the first project in New England to showcase grass test plots, densification equipment, and an EvoWorld biomass boiler that burns the grass.

Meach Cove Farms began collaborating with Dr. Sidney Bosworth of the University of Vermont College of Agriculture and Life Sciences and the Vermont Bioenergy Initiative in 2009 to assess the potential of different species of grass as solid biofuel for heating applications.

In September 2011 Meach Cove Farms was awarded an USDA Natural Resources Conservation Service Conservation Innovation Grant to research the feasibility of Vermont grown grass pellets and heating equipment potential as an emerging renewable energy source in Vermont. The biomass boiler being featured at the Open House was funded through a Conservation Innovation Grant (CIG) administered by the Natural Resources Conservation Services.

IF YOU GO:

Meach Cove Farms is located at 310 Beach Road in Shelburne (off Bostwick Road, 1.6 miles west of Rte 7). The Open House runs from 9 am – 12 noon both Friday and Saturday, October 23-24. There is no cost and both days are open to the public. More info at www.meachcovefarms.org, 802-985-9218.

14 Sep 2015

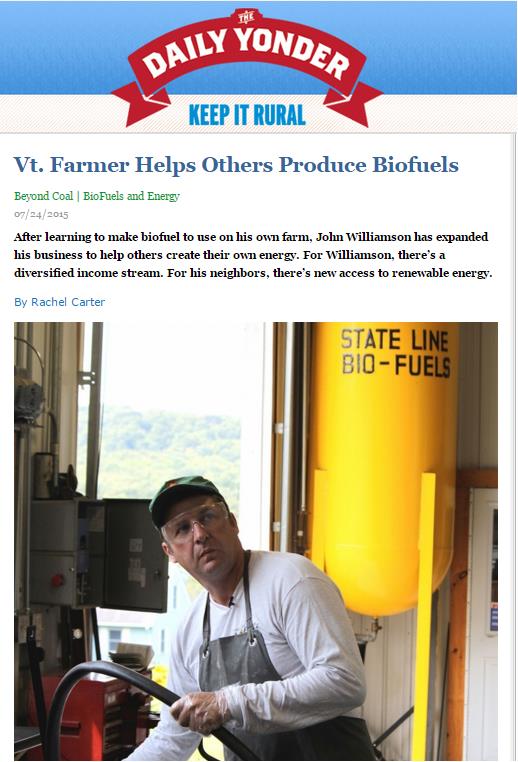

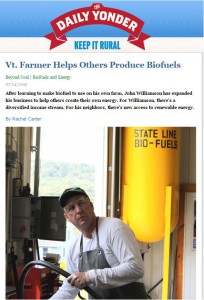

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

Efficiency Vermont, Renewable Energy Resource Center, Renewable Energy Vermont and Clean Energy Development Fund combine efforts to bring up to $5,500 in rebates to Vermonters who heat local

Efficiency Vermont, Renewable Energy Resource Center, Renewable Energy Vermont and Clean Energy Development Fund combine efforts to bring up to $5,500 in rebates to Vermonters who heat local

Through a generous opportunity, Vermonters now have a short-time frame before the new year to capitalize on a fantastic incentive offering that helps them save money, while supporting Vermont jobs and sustainable forests, while making sure they stay warm this winter.

Vermonters can get up to $5,500 to help switch from fossil fuel to local wood heating. Cash incentives are available from the Clean Energy Development Fund and Efficiency Vermont. Renewable Energy Vermont and the Renewable Energy Resource Center have partnered to help promote the incentives.

“We’ve been very happy with our decision to switch to a wood pellet boiler. Not only do we save money every year on our fuel bill, but we also love the fact that we’re helping to keep forests intact and logging jobs going,” says Mark Bushnell of Middlesex.

Vermonters who make the switch to wood pellet fuel typically save $1,500 annually when compared to oil and propane fuel heating options. And for those who are used to whole-home heating through their traditional boiler, the wood pellet boiler keeps it simple and complete. Advanced wood pellet boilers are fully automatic, so there’s no work for the home or business owner.

“I heated my home for years with a standard wood stove, but I’m happier with my wood pellet boiler. The new boiler is much more efficient and better for the environment because it is cleaner burning. And it feels great to be off fossil fuels,” says Susan Clark of Middlesex.

Wood pellet boilers, though not well known in the United States, are the primary way of heating in some parts of the world, including Upper Austria where more than 40,000 homes and businesses heat with wood from their background in an easy, seamless way. In fact, the State of Vermont and Upper Austria are involved in a Sister Statehood Agreement to help learning across both sides of the Atlantic to increase the uptake of this sustainable, local heating option.

“For many years, Vermont has been a national leader in the use of modern wood heating systems in large buildings like schools, office buildings, and apartment buildings. With pellets now available in bulk using specialized delivery trucks that conveniently blow pellets into a fuel bin and heating systems that are fully-automated, many homeowners and small businesses are also making the switch from oil and propane,” said Adam Sherman of the Biomass Energy Resource Center.

For more information, please go to www.advancedwoodheat.com

Media Contacts:

Renewable Energy Vermont, Ansley Bloomer, ansley@revermont.org (802) 595-0723

Biomass Energy Resource Center, Alayna Howard, ahoward@veic.org (802) 540-7656

Renewable Energy Resource Center, Alayna Howard, ahoward@veic.org (802) 540-7656

Efficiency Vermont, Alayna Howard, ahoward@veic.org (802) 540-7656

Clean Energy Development Fund, Andrew Perchlik, andrew.perchlik@state.vt.us (802) 828-4017

17 Aug 2015

The Third Annual National Bioenergy Day

The T hird Annual National Bioenergy Day (NBD), which will take place Wednesday, October 21st, is a day that is marked with events from across the country that celebrates energy independence, local jobs, and many other benefits of local bioenergy. Led by Biomass Power Association in partnership with U.S. Forest Service, National Bioenergy Day is an opportunity for Vermonters to showcase our research, progress, and impacts in producing local bioenergy for local use.

hird Annual National Bioenergy Day (NBD), which will take place Wednesday, October 21st, is a day that is marked with events from across the country that celebrates energy independence, local jobs, and many other benefits of local bioenergy. Led by Biomass Power Association in partnership with U.S. Forest Service, National Bioenergy Day is an opportunity for Vermonters to showcase our research, progress, and impacts in producing local bioenergy for local use.

How To Get Involved:

- Organize an event on or near October 21ndthat showcases bioenergy as a clean, efficient, and resourceful way to produce energy. Emphasizes bioenergy’s role in improving environmental health; and facilitates collaboration along the supply chain.

- Partner with someone who works in the bioenergy supply chain to create an event. Use the Vermont Energy Atlas to find partners in your area.

- Piggyback on an existing event and call it a NBD event.

- Share and talk about NBD in your social media and press efforts while promoting impacts in your community.

The Vermont Bioenergy Initiative, for example, will spend the day re-capping and previewing events and research on our Twitter handle @VTBioenergy that took place throughout the summer and that are planned for the fall. We’ll be recapping and sharing exciting things like the exciting learning opportunities at the University of Vermont, Full Sun Company’s Biodiesel and Meal production, and much more!

For more information, you can visit also visit bioenergyday.com and follow @USAbiomass on twitter!

Click Here for National Bioenergy Day Participation Guide!

13 Jul 2015

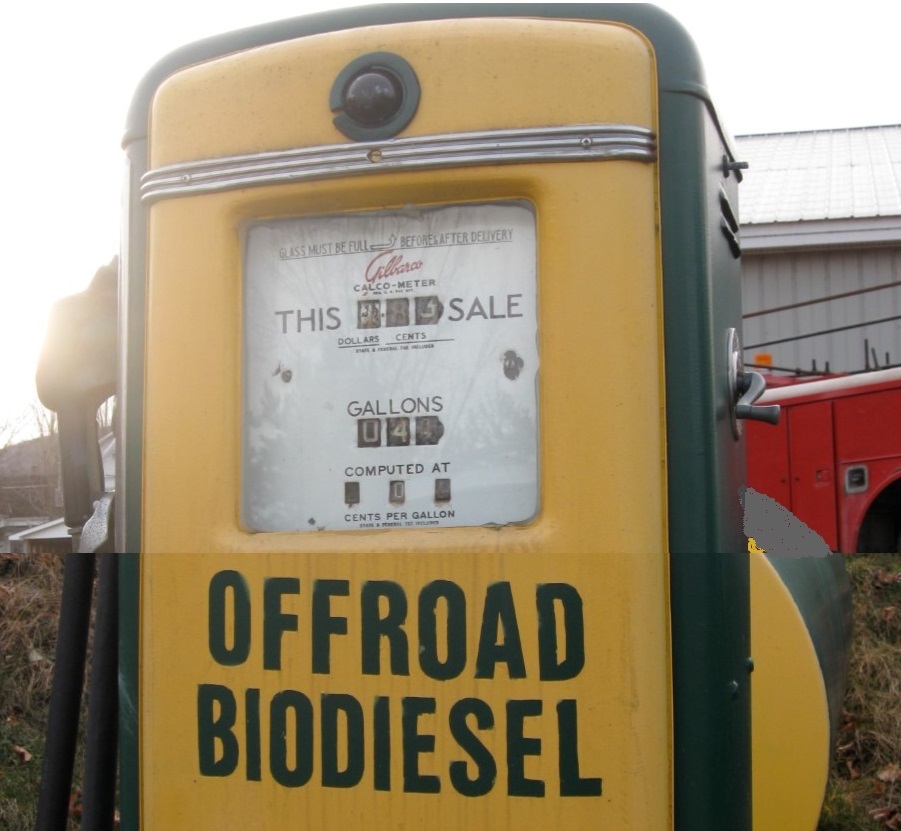

Making Biofuel

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

01 Jun 2015

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

2014 was a busy year for the Vermont Bioenergy Initiative as we engaged in national outreach efforts to share our work connecting diversified agriculture and local renewable energy production for on-farm and community use in ways that be applicable to rural areas around the country. These rural areas are often at “the end of the pipeline” and are subject to higher and more volatile costs for energy. The Vermont Bioenergy Initiative “local production for local use” model shows that rural communities can produce some of their own energy, thereby improving their energy security and benefitting from more predictable and affordable energy prices. Any farm in any part of the country can grow and process their own fuel, using the best practices developed by the collaborating farms and UVM Extension researchers working in partnership with the Vermont Bioenergy Initiative. Funding for our program work to support research, technical assistance, and infrastructure development in emerging areas of bioenergy was secured by US Senator Patrick Leahy and the US Department of Energy.

Recent news we distributed to local, regional, and national audiences includes:

Local production for local use is biofuel model that works in Vermont.

Vermont sunflowers to help provide biodiesel power.

We have worked with several regional and national publications to secure editorial specifically featuring oil crops for on-farm biodiesel and feed, and grass energy for heating.

Check out the recent interview with our UVM Extension consultant and agricultural engineer, Chris Callahan in Biofuels Journal.

Read about alternative energy innovations on the farm featuring farms a part of the Farm Fresh Fuel Project in Farming Magazine.

The Grass Energy Report we released summer 2014 was featured extensively in both Renewable Energy World and On Pasture Magazine.

Visit the Green Energy Times website for our ongoing column, Emerging Frontiers in Bioenergy and follow the Vermont Bionenergy on Twitter for current news, trends, and tweets on renewable energy in Vermont and beyond.

Bioenergy: Biomass to Biofuels; is an innovative new textbook that provides insight into the potential and current advances and benefits of biofuel. Contributions include an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories. The text is edited by Anju Dahiya, cofounder of General Systems Research, LLC and lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, both of which stand as leaders in cutting-edge topics such as microbial fuels and biogas. The chapters of the book are divided into solid, liquid and gaseous biofuels, and further explore cost-effective production as well as discussions covering economics, environment and policy.

Organized into seven accessible sections, Bioenergy: Biomass to Biofuels begins with an in-depth overview of the transformation of biomass into biofuels. Once the basics are covered, readers move on to the technical applications of solid feedstocks, such as wood and grass, and their transformation into biofuels. The following section discusses biomass to liquid biofuels—text focuses on oilseeds, cellulose ethanol, and algae as feedstocks. Anaerobic digestion is explored in a section outlining gaseous fuels and bioelectricity and focuses primarily on livestock manure feedstocks. Throughout the chapters, the tradeoffs and benefits of these different feedstocks are outlined through deeper analysis.

Multiple chapters focus in detail on conversion pathways for cost effective biofuel production. The myriad of topics include basic biodiesel production efficiency, converting petroleum-based infrastructure into biorefineries, reducing enzyme cost through varying combinations, and sustainable aviation biofuels. The text concludes with a robust section that connects biofuels to a big picture perspective—economics, sustainability, environmental implications, and policy are examined closely in relation to renewable resources, future uncertainties, and entrepreneurship.

Bioenergy: Biomass to Biofuels is structured to meet the needs of professionals finding their way in the field, students in need of an introduction, and instructors establishing a course on biofuels. Case studies on provided topics are found at the end of every section and are based on documented implementation projects. Bioenergy: Biomass to Biofuels is available for purchase on the Elsevier publisher website. Editor Anju Dahiya, owner of General Systems Research in Burlington, Vermont and is a Vermont Bioenergy Initiative grant recipient to advance research and applications of converting algae into biofuel.