![energy[1]](http://vermontbioenergy.com/wp-content/uploads/2015/12/energy1-300x141.gif) Following the Fall Semester UVM bioenergy course Bioenergy: Biomass to Biofuels, the University of Vermont will be offering a new bioenergy course this spring entitled Waste to Energy: Community Development Application. The course will again be taught by Anju Dahiya, cofounder of General Systems Research, LLC (GSR), lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and a Vermont Bioenergy Initiative algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Following the Fall Semester UVM bioenergy course Bioenergy: Biomass to Biofuels, the University of Vermont will be offering a new bioenergy course this spring entitled Waste to Energy: Community Development Application. The course will again be taught by Anju Dahiya, cofounder of General Systems Research, LLC (GSR), lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and a Vermont Bioenergy Initiative algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

![food-waste[1]](http://vermontbioenergy.com/wp-content/uploads/2015/12/food-waste1-300x72.gif) In a Vermont post Act 148, the universal recycling law for solid waste, food waste, dairy farm manure, municipal wastes, landfill waste, carbon exhaust, nutrient runoff and other materials not being converted into value products are all resources that hold potential energy that can be developed in a sustainable way to power a local economy. This class focusing on waste sourced bioenergy comes on the heels of a promising results and continued work by Dahiya’s company GSR on incorporating algae into Green Mountain Power’s anaerobic digester at Nordic Farms in Shelburne, Vermont. The product serves as a strong example in which excess nitrogen and phosphorus in cow manure would find its way off farmland and end affecting health of natural water bodies, but instead is harnessed to make electricity and biofuel. As listed in the course catalog “the mission of this program is to provide hands-on instruction in all possible Bioenergy areas, support generation of related skilled workforce and stimulate sustainable energy production.”

In a Vermont post Act 148, the universal recycling law for solid waste, food waste, dairy farm manure, municipal wastes, landfill waste, carbon exhaust, nutrient runoff and other materials not being converted into value products are all resources that hold potential energy that can be developed in a sustainable way to power a local economy. This class focusing on waste sourced bioenergy comes on the heels of a promising results and continued work by Dahiya’s company GSR on incorporating algae into Green Mountain Power’s anaerobic digester at Nordic Farms in Shelburne, Vermont. The product serves as a strong example in which excess nitrogen and phosphorus in cow manure would find its way off farmland and end affecting health of natural water bodies, but instead is harnessed to make electricity and biofuel. As listed in the course catalog “the mission of this program is to provide hands-on instruction in all possible Bioenergy areas, support generation of related skilled workforce and stimulate sustainable energy production.”

![nutrients-pic-1[1]](http://vermontbioenergy.com/wp-content/uploads/2015/12/nutrients-pic-11-300x93.gif) Lectures will be held every on campus every Friday during the UVM spring semester from 12:00 pm to 3:00 pm, with 5 additionally required off campus field trips. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held every on campus every Friday during the UVM spring semester from 12:00 pm to 3:00 pm, with 5 additionally required off campus field trips. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

At Borderview Farm in Alburgh, Roger Rainville’s dairy-turned-energy farm makes biodiesel from locally-grown sunflower seeds.

At Borderview Farm in Alburgh, Roger Rainville’s dairy-turned-energy farm makes biodiesel from locally-grown sunflower seeds.

In 2008, when diesel prices rose from $4 to $5 per gallon, Rainville began experimenting with farm-scale biodiesel production. With guidance from UVM Extension and grant funding from the Vermont Bioenergy Initiative, Rainville began planting sunflowers on a portion of his 214 acres and installing biodiesel processing equipment. Oilseed sunflowers (as opposed to confectionary sunflowers that are grown for eating) are the most popular oilseed crop in Vermont, with hundreds of acres planted statewide. The crop is grown in rotation with grains and grasses and yields high quantities of oil.

Harvesting, Cleaning, and Pressing

Following harvest with a combine, a seed cleaner and grain dryer are used to prepare the seeds for storage in a 200-ton grain bin prior to processing. A flex auger system moves the seeds from the storage bin into hoppers on each press, and screw augers push the seed through a narrow dye at the front of the press. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The oil can then be used as culinary oil for cooking or further refined into biodiesel. The leftover seed meal is used for livestock feed, fuel for pellet stoves, or fertilizer for crops.

Biodiesel Processing

The small-scale biodiesel production facility at Borderview Farm is an 800 square foot insulated and heated building (the space does not need to be heated, but the oil should be stored where it will not freeze) that houses an oil press, a BioPro 190 automated biodiesel processor, a methanol recovery system, and a set of dry-wash columns for cleaning the fuel. The clean oil at the top of each settling tank is added to the BioPro 190 processor along with lye, methanol, and sulfuric acid. The automated processor runs through several stages of processing in about 48 hours (esterification, transesterification, settling, washing, and drying), with one break after 24 hours to remove the glycerin byproduct.

Safety equipment in the processing facility includes personal protective equipment like aprons, gloves, eye protection, a ventilation system, gas detectors, and spill containment materials. At Borderview Farm a set of standard operating procedures hangs on the wall and blank check-sheets are in a binder to make the process easy to repeat. The finished biodiesel is stored in 250 gallon pallet tanks making distribution to different farms easier. The installed capacity of the facility can process 100 tons of seeds from 138 acres of sunflowers per year, yielding 10,500 gallons of biodiesel and 64 tons of sunflower meal (assuming the state average yield of 1,500 pounds sunflower seeds per acre and operation of 24 hours per day for 260 days per year).

Rainville switched from purchasing diesel for five tractors and one truck to making his own biodiesel. He wanted to be independent of imported fuel, and liked creating a new way for farmers to diversify. “Using land for making biodiesel is not the most economical option compared to some other crops, but it’s about creating opportunities to try something different,” says Rainville.

Cost Benefits

Rainville’s annual biodiesel use has ranged from 500 to 3,000 gallons per year. At current prices (over $4 per gallon for diesel and $2.29 per produced gallon of biodiesel) biodiesel has saved him from $500 to $4,000 per year in fuel costs. He also emphasizes energy independence as an added benefit. Plus, any growers that also raise livestock can use the meal, which is leftover after the oil is extracted, as part of their feed rations. Rainville recommends talking with an animal nutritionist to blend this into feed at the right ratio, since sunflower meal has a high fat content.

This story was originally released in a series of energy case studies showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production—all of which are components for helping Vermont reach the renewable energy and environmental impact goals of the Farm to Plate Strategic Plan. Learn more at www.vtfarmtoplate.com.

02 Nov 2015

Vermont Bioenergy Initiative proves biofuel potential for state and concludes ten year project

By: Ellen Kahler

VT Bioenergy Team – L to R (Chris Callahan – UVM Extension, Kirk Shields — Green Mountain Power, Christy Sterner – US DOE, Larry Scott – Ekolott Farm, Ellen Kahler – VSJF, John Williamson – Stateline Biofuels) at Green Mountain Power’s Energy Innovation Center in Rutland

Vermont can produce more of its own biofuel energy and the environmental and potential economic benefits of local bioenergy have been proven by the Vermont Bioenergy Initiative – a program of the Vermont Sustainable Jobs Fund. Since 2005, the Vermont Bioenergy Initiative has invested more than $2.5 million in innovative bioenergy research, projects, and people so Vermont can locally produce more of the state’s energy needs – from a variety of agricultural and algal feedstocks.

US Senator Patrick Leahy made the investment at this scale possible through Congressionally Directed Awards from the US Department of Energy (US DOE). The funding concludes in early 2016, at which point a complete impact report will be released by the Vermont Sustainable Jobs Fund, who has served as the intermediary between the US DOE and 52 individual Vermont bioenergy projects over the past ten years.

Research, development, and early stage demonstration projects have included:

- Investing in 2 on-farm methane digesters;

- Building farm-scale infrastructure to turn oilseed crops such as sunflowers into biodiesel to run farm tractors;

- Growing switchgrass and densifying it into “pucks” that are burned in a high efficiency commercial boiler instead of propane;

- Identifying the most lipid producing strains of native Vermont algae which can feed off the excess nutrients from methane digesters and can eventually be harvested to make biodiesel or jet fuel;

- Developing two “Biomass to Biofuels” college level courses which run repeatedly at UVM and VT Tech to inspire and train the next generation of bioenergy experts and technicians;

- Exploring the logistics of bulk wood pellet delivery systems to Vermonters’ homes;

- Organizing a number of learning opportunities and conferences for oilseed, grass and algae researchers, farmers and entrepreneurs to attend;

- Providing agronomic and engineering support to oilseed and grass farmers;

- Educating the general public about why the local production for local use of energy crops from Vermont farms and forests makes good economic and ecological sense.

VT Bioenergy Team 2 – L to R (Roger Rainville – Borderview Farm, Christy Sterner – US DOE, Heather Darby – UVM Extension, Natasha Rainville – Borderview Farm) at Borderview Farm, Alburgh VT

The Vermont Bioenergy Initiative is a unique effort and one that is gaining resonance in other parts of rural America. The initiative’s resource website, www.VermontBioenergy.com is utilized by biofuel producers, educators, and technical service providers from across the country.

The work conducted over the past ten years by the Vermont Bioenergy Initiative to conduct research, provide technical assistance, and develop infrastructure in emerging areas of bioenergy will continue with the initiative’s partners at UVM Extension and the Vermont Agency of Agriculture, Food & Markets. As Vermont moves forward – being innovative and increasingly focused on generating renewable energy from the land and forests – the research and infrastructure the Vermont Bioenergy Initiative has invested in over the past ten years will endure and spawn the next wave of bioenergy development in the state.

Ellen Kahler is executive director of the Vermont Sustainable Jobs Fund (VSJF), a non-profit organization created by the State of Vermont to help develop Vermont’s sustainable agriculture, renewable energy, and forest product businesses. Since 2005, the Vermont Bioenergy Initiative has been a VSJF program that connects diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. Learn more at www.VermontBioenergy.com.

Algae for biofuel has been a long time component of the local biofuel production for local use model pioneered by the Vermont Bioenergy Initiative. At the forefront of these efforts has been Anju Dahyia, a VBI grantee, lead biofuels instructor at the University of Vermont, and president of General Systems Research (GSR) Solutions. When the Vermont Fuel Dealers Association received a USDA Rural Business Enterprise Grant to utilize waste materials from Vermont farms to produce sustainable distillate fuel, Anju and GRS Solutions were already in a prime positon to conduct the necessary research.

Algae for biofuel has been a long time component of the local biofuel production for local use model pioneered by the Vermont Bioenergy Initiative. At the forefront of these efforts has been Anju Dahyia, a VBI grantee, lead biofuels instructor at the University of Vermont, and president of General Systems Research (GSR) Solutions. When the Vermont Fuel Dealers Association received a USDA Rural Business Enterprise Grant to utilize waste materials from Vermont farms to produce sustainable distillate fuel, Anju and GRS Solutions were already in a prime positon to conduct the necessary research.

GSR is developing a method of producing algae biofuel to replace traditional fossil fuels in motor vehicles, heavy farm equipment, and even airplanes at Charlotte’s Nordic Dairy Farm as a second tier to the already operational anaerobic digesters contributing to Vermont’s distributed energy generation grid. The process to produce algal biofuel has the potential to prevent nutrients such as phosphorus and nitrogen from making their way into local lakes and waterways. Nordic Dairy Farm’s owner, Clark Hinsdale, explained at a recent press event on his farm: “the best way to capture excess nutrients on farms is to never let them get beyond the boundaries of the farmstead.”

The current anaerobic digestion system “Cow Power,” utilized by Green Mountain Power, functions by using the methane byproduct harvested from constantly produced cow manure to make electricity that then is sold to Green Mountain Power customers. The research done by GSR focuses on another byproduct of digestion – the nutrient dense liquid waste, previously left unused for power purposes.

The oleaginous algae strains that Anju Dahyia has been working with since 2008 thrive on this dense waste and after the algae has consumed the available nutrients, the creation of the distillate fuel can begin. The result makes the process a closed loop system, and means that dairy farmers like Nordic Dairy (whose cows produce up to a ton of manure a day) would be able to sell algae derived biofuel to local fuel dealers and create granular organic fertilizer. According to Dahyia, Hinsdale’s 300 cows alone have the potential to produce anywhere between 20,000 to 30,000 gallons of biofuel each year.

The cost of production is estimated at $20 dollars per gallon, but Dahyia thinks that with increased scale will come a decreased price. At the recent press conference at the Nordic Dairy Farm site early in September, Mary Powell of Green Mountain Power outlined how the company is working with GSR Solutions to help increase scale and add more small refineries that mimic this operation. She went on to note the resiliency a community-sized digester refinery can add to a microgrid.

Speaking to ABC local 22 News, Matt Cota, Director of the Vermont Fuel Dealers Association added, “We know that bio-heat, renewable blended fuel, combined with heating oil works in customers tanks and burners, so if we can source that locally, it would be a great thing for Vermont’s economy, for Vermont famers, Vermont fuel dealers and consumers all across Vermont.”

Richard Altman of the non-profit Commercial Aviation Fuels Initiative was also in attendance and trumpeted that “community-scale digester-refineries in the region might be feasible by 2020,” noting that this project is just a start.

Also on the horizon, GRS Solutions is already working to go further with this technology by incorporating food waste into this digester system. While this system may be in its early stages, one thing is for sure, Vermont energy stakeholders are lining up to show their support and contribute to this more than viable option for local energy production.

For more watch the local WCAX coverage of the September 3rd press conference and to learn more about Algae Bioenergy in Vermont see our other post Algae Biofuel – Vermont’s Search for Viable and Cost-Effective Methods

19 Oct 2015

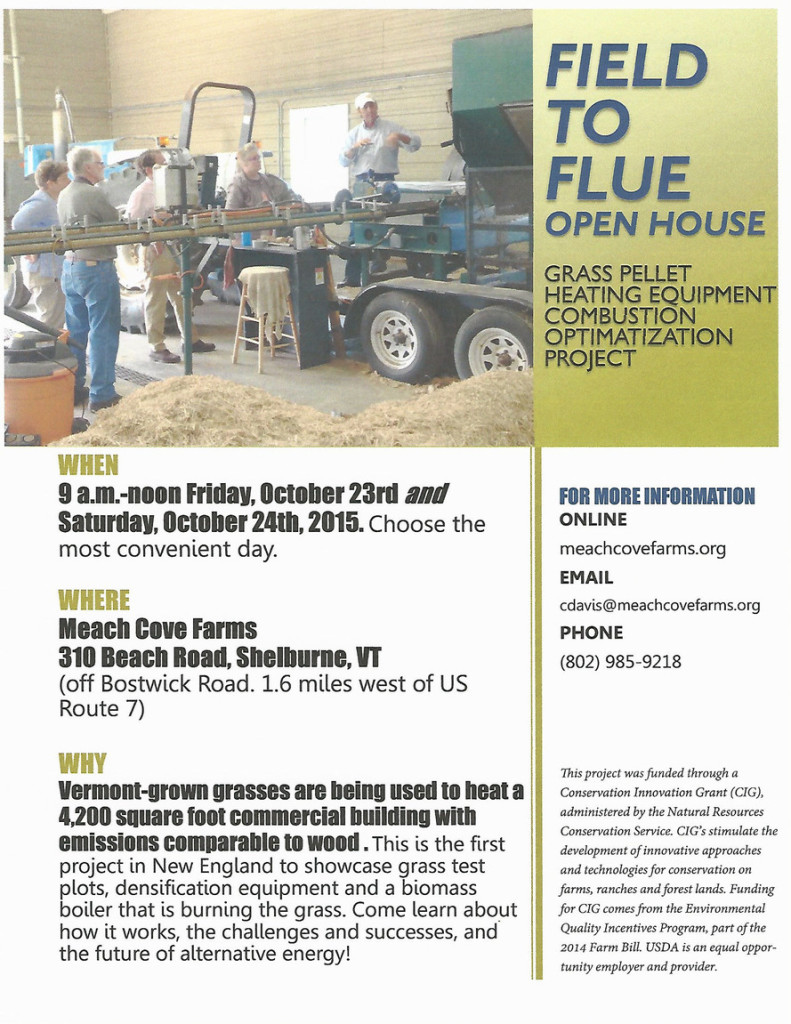

Field to Flue Open House at Meach Cove Farms

Vermont-grown grasses are being used to heat the Biomass Building – a 4,200 square foot commercial building at Meach Cove Farms in Shelburne. Local residents, community leaders, and renewable energy enthusiasts are invited to visit Meach Cove Farms Friday, October 23 – Saturday, October 24 for an Open House to learn how grass pellets are generating heat in a biomass boiler – an emerging source of bioenergy in Vermont.

Meach Cove Farms is a 1,000-acre certified organic farm primarily growing soy beans, wheat, rye, and corn as well as wine grapes, woodlands, and switchgrass trial plots for use in grass energy production. The Open House will offer a complete demonstration of the Grass Pellet Heating Equipment Combustion Optimization project – the first project in New England to showcase grass test plots, densification equipment, and an EvoWorld biomass boiler that burns the grass.

Meach Cove Farms began collaborating with Dr. Sidney Bosworth of the University of Vermont College of Agriculture and Life Sciences and the Vermont Bioenergy Initiative in 2009 to assess the potential of different species of grass as solid biofuel for heating applications.

In September 2011 Meach Cove Farms was awarded an USDA Natural Resources Conservation Service Conservation Innovation Grant to research the feasibility of Vermont grown grass pellets and heating equipment potential as an emerging renewable energy source in Vermont. The biomass boiler being featured at the Open House was funded through a Conservation Innovation Grant (CIG) administered by the Natural Resources Conservation Services.

IF YOU GO:

Meach Cove Farms is located at 310 Beach Road in Shelburne (off Bostwick Road, 1.6 miles west of Rte 7). The Open House runs from 9 am – 12 noon both Friday and Saturday, October 23-24. There is no cost and both days are open to the public. More info at www.meachcovefarms.org, 802-985-9218.

![12038666_988361397888752_7565829410015974342_o[2]](http://vermontbioenergy.com/wp-content/uploads/2015/10/12038666_988361397888752_7565829410015974342_o2-1024x731.jpg) On October 6th, Seventh Generation and the University of Vermont welcomed the 45th US Vice President, Al Gore at Ira Allen Chapel on the university’s campus. The highly anticipated speaking engagement entitled “The Climate Crisis and the Case for Hope,” which is part of an Energy Action Seminar Series facilitated by UVM Energy Alternatives, was truly an emotional roller coaster and had Gore left the stage at the halfway mark, all in attendance would have gone home rather depressed. “We are going to win this struggle” he stated, “the question is how quickly we will win,” Gore remarked before elaborating on the deep sinkhole humanity has fallen into.

On October 6th, Seventh Generation and the University of Vermont welcomed the 45th US Vice President, Al Gore at Ira Allen Chapel on the university’s campus. The highly anticipated speaking engagement entitled “The Climate Crisis and the Case for Hope,” which is part of an Energy Action Seminar Series facilitated by UVM Energy Alternatives, was truly an emotional roller coaster and had Gore left the stage at the halfway mark, all in attendance would have gone home rather depressed. “We are going to win this struggle” he stated, “the question is how quickly we will win,” Gore remarked before elaborating on the deep sinkhole humanity has fallen into.

The lecture followed a path most familiar with the former vice president’s advocacy would expect. The rising atmospheric greenhouse gas (GHG) levels that we are witnessing come from a variety of sources, but as Gore pointed out “the main problem is burning of fossil fuels, when we address this, the rest will fall into place.” The first part of the lecture really focused on the crisis. The audience watched in horror footage of major weather events, many have seen before, but taken in all at once really underline the major recent changes that we have seen in our global weather patterns. Gore noted that of the “14 of the hottest years on record have been in the last 15 years,” and that the average temperature at night during this time has increased, meaning that people and the planet, really can’t get a break from the heat.

Gore went on to talk about the cost of carbon, or as he tried to drive home, the lack of cost it represents to our economy. “We need to put a cost on carbon,” he noted “put a cost on denial” he then continued in reference to those who deny climate change. This statement was met by large applause by those who filled Ira Allen Chapel, hitting home for a crowd that will likely be talking a lot about carbon pricing in the upcoming legislative session. Political instability, floods and mudslides, wildfires, drought, storm damage, dying coral, infrastructure loss, species extinction, melting glaciers, famine water security, ecosystem loss, our way of life, infectious disease, and sea level rise all represent the cost of carbon we are already paying Gore noted on a slide with an animated cash register racking up the cost, concluding “there is a financial risk to using fossil fuels”

It’s worth noting, that this notion does not make Gore an outlier anymore. Just last week the Governor of the bank of England, Mark Carney echoed the same message when he spoke on the increase of major weather events and the related financial cost at meeting of leading insurers at Lloyd’s of London. Additionally, going back to last year, the department of defense listed climate change as an agitating factor in areas already experiencing political instability.

As was said earlier, if Gore had sent everyone home after the “The Climate Crisis” part of his lecture, without the “Case for Hope” portion, everyone there would have a pretty doomy and gloomy demeanor for weeks to come. Instead, the mood took a 360 change with Gore trumpeting the triumphs of the past year that have put humanity on a course towards beating climate change. Among these he gave Burlington credit for achieving 100% renewable energy. He went on the new power generated in 2014 three quarters of it was renewable energy, and reflecting on the fact that those who still deny climate change can agree, renewables just make economic sense.

To close, Gore instructed the audience, “always remember, that political will is a renewable resource.” As Vermont and the rest of the nation watch national and local campaigns for political office start up in which politicians’ attention, or potential lack of attention, can greatly shape our climates future, let’s hope that holds true. Leaving Ira Allen Chapel, one couldn’t help but feel a sense of optimism, and optimism is definitely a renewable resource.

The full seminar “The Climate Crisis and the Case for Hope” can be heard courtesy of the Gund Institute for Ecological Economics

05 Oct 2015

2015 New Economy Week

The 2015 Vermont New Economy Week starts Saturday October 10th and runs until Saturday the 17th, with plenty of free opportunities to experience public conversation about the ideas that can transform society and build an economy where people and the planet matter. The New Economy movement is “a people-driven approach to achieving prosperous communities, successful businesses, and healthy environments.” Participants in the Vermont New Economy Week can experience this vision, learn of opportunities to get involved, and see the progress of the Vermont New Economy. One such opportunity is part of the ongoing Energy Action Seminars occurring at the University Of Vermont, featuring Yoram Bauman PhD, the world’s only “Stand-up” Economist and a RE2015 keynote Speaker, who will discuss “Carbon Taxes, Why We Need Them.”

The Vermont New Economy Week falls one month before the New Economy Coalition hosts the national “New Economy Week: From Austerity to Prosperity” from November 9th to the 15th. Over a five day period, this national week will seek to highlight five “pressing challenges” by releasing original online content ranging from interviews, traditional publications, and Twitter conversations. The five pressing challenges in which the New Economy Coalition hopes spark a conversation around with the intention to bring societal change that can build an economy where the planet and people matter are,

- Day 1:Good Work and Opportunity for All

- Day 2:Building an Economy Where #BlackLivesMatter

- Day 3:Democracy Versus the 1%

- Day 4:A People’s Climate Agenda

- Day 5:Enough to Go Around

Almost all of these events are free and open to the public, with a few that suggest a small donation so those hosting the events can continue their work re-envisioning our economic system. For more information on the Vermont New Economy Week 2015 events below, read more on the Donella Meadows Institute page! To learn more about New Economy Coalition’s “New Economy Week: From Austerity to Prosperity” from November 9th to the 15th visit http://www.neweconomyweek.org/

For more about reimaging the Vermont economy, read our post Summit on Creating Prosperity and Opportunity Confronting Climate Change – Looking Back and Looking Forward

Vermont New Economy Week Opportunities

- Prelude to New Economy Week, October 10

- 10:00am-2:30pm— Weaving Well-Being Festival, State House Lawn, Montpelier

- Monday, October 12

- 6:00pm-9:00pm — Carbon Taxes, Why We Need Them, Energy Action Seminar, 108 Lafayette Hall, UVM, Burlington

- Wednesday, October 14

- 2:00pm-6:30 pm —Investing in the New Economy: Transforming Investments for Climate and Community, Chase Center, Vermont Law School, South Royalton

- Thursday, October 15

- 5:00pm-6:30pm — Green Drinks: Divestment for Sustainable Investment, with guests Gwen Hallsmith, author of “Vermont Dollars, Vermont Sense” and Steve Aldrich of the White River Investment Club, Worthy Kitchen, Woodstock

- 6:00pm-9:00pm —Worker Co-ops in the New Economy: An Evening of Short Films and Discussion, Artsriot, Burlington

- Friday, October 16

- 4:30-6:30 pm – Who is Responsible for Climate Change? Perspectives from Science, Ethics, Policy, and Law. Sustainability Solutions Cafe’, Filene Auditorium, Dartmouth College, Hanover

- Postlude to New Economy Week, Saturday, October 17

- 9:30am-3:30pm—Vermont Interfaith Power and Light Conference “Leading Action on Climate: Tools for Faith Communities”, Christ Episcopal Church, Montpelier

- 6:00 – 8:00 pm – New Economistas CD Release Party, Bagito’s Restaurant, Montpelier

David Marchant and Jane Sorensen of River Berry Farm—an organic vegetable and fruit producer in Fairfax—were early adopters of biomass heating when they installed a corn and pellet furnace in one of their greenhouses in 2008. The furnace required manual lighting and was snuffed out often when strong winds blew, and did not produce reasonable heat. “I kept thinking, there has got to be a better option,” recalls David, “It was a real labor burden, and you couldn’t count on it.”

David Marchant and Jane Sorensen of River Berry Farm—an organic vegetable and fruit producer in Fairfax—were early adopters of biomass heating when they installed a corn and pellet furnace in one of their greenhouses in 2008. The furnace required manual lighting and was snuffed out often when strong winds blew, and did not produce reasonable heat. “I kept thinking, there has got to be a better option,” recalls David, “It was a real labor burden, and you couldn’t count on it.”

Based on their early experiences and bolstered by a commitment to long-term sustainability and reduced fossil fuel dependence, River Berry Farm opted to host a biomass heating demonstration project. This time, they opted for a higher-rated boiler rather than a furnace. Boilers produce hot water, rather than hot air, which allows more options for distributing the heat. The new system also had an automated propane ignition system.

The biomass heating demonstration was part of a UVM Extension project aimed at trialing several furnaces in agricultural heating applications with funding support provided by the High Meadows Fund. According to Chris Callahan, Ag Engineer with UVM Extension Agricultural Engineering Program who assisted with some of the design and performance assessment, “The main lessons learned from these early installations were to buy high quality fuel, seek improved automatic ignition controls, invest in a good chimney and install it well, and know the actual heat output rating of the unit.”

Modern biomass heating appliances generally include a fuel storage bin, an auger for feeding fuel to the appliance, the appliance itself (boiler or furnace) with an ignition system, a combustion chamber, a heat exchanger, and a heat distribution system. They also incorporate some means of controlling combustion, fuel feed rate, and air flow and often include emissions control measures and automated ash removal.

The selected boiler was a Central Boiler Maxim 250 with a 250,000 BTU/hr input rating, efficiency of 87.8%, and EPA Phase II Hydronic Heater qualification. “The boiler makes hot water which we can use in multiple greenhouses by plumbing it to them in insulated PEX piping. Once in the greenhouse, we convert to hot air with a hot water fan coil, put it in the ground for root-zone heating or on the benches in our mat-heating system for starts,” says Marchant. “I like it. I keep trying to find something wrong with it, but I can’t. The payback period is a bit longer due to higher initial costs, but you have to expect that.”

The basic system cost was approximately $13,000 for the boiler, bin, pad, and plumbing to a hot water fan coil. The other heat distribution systems included in-ground PEX, heat exchange, and plumbing for a bench heat system and added approximately another $5,000. The system is more automated and reliable than the earlier furnace was, but the higher initial costs and the fact that the system is only used 3 months out of the year do prolong the payback period to about 12 years when compared with a propane furnace. If the system was used for 6 (space heating) or even 12 months (wash water, pasteurization) of the year the payback would be halved or quartered, respectively.

“In addition to the financial payback, the carbon emissions avoidance is also of interest to many people,” says Callahan, “In River Berry Farm’s case, the Maxim is helping them avoid 5,910 pounds of net CO2 emissions per year which is about equivalent to 5,000 miles car travel or the CO2 sequestered by half an acre of pine forest.”

Learn more about UVM Extension’s Agricultural Engineering Program at.

This story was originally released in a series of energy case studies showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production—all of which are components for helping Vermont reach the renewable energy and environmental impact goals of the Farm to Plate Strategic Plan. Learn more at www.vtfarmtoplate.com.

Renewable energy businesses, technology leaders, energy generators, utilities and environmental organizations along with policy makers and communities will convene in Burlington this month to identify tangible strategies for converting the state’s fossil fueled economy to one driven by renewable sources. Renewable Energy 2015 (RE 2015) is Vermont’s premier event exploring the transition to a clean energy economy. The 15th annual business conference, hosted by Renewable Energy Vermont (REV) is slated for October 8 and 9 at the Sheraton Hotel and Conference Center in Burlington, VT.

Renewable energy businesses, technology leaders, energy generators, utilities and environmental organizations along with policy makers and communities will convene in Burlington this month to identify tangible strategies for converting the state’s fossil fueled economy to one driven by renewable sources. Renewable Energy 2015 (RE 2015) is Vermont’s premier event exploring the transition to a clean energy economy. The 15th annual business conference, hosted by Renewable Energy Vermont (REV) is slated for October 8 and 9 at the Sheraton Hotel and Conference Center in Burlington, VT.

With expert speakers on a diverse array of topics, this dynamic forum will look at the opportunities and hurdles involved in moving toward an integrated energy infrastructure addressing power, heating and transportation needs. The conference spans two days and features over 25 conference sessions with more than 65 speakers from throughout the region.

Topics covered include: wind, solar, bioenergy technologies, transportation, resilient grid technology, energy efficiency and energy storage solutions. Conference sessions will look at hurdles to implementing renewables as well as untapped opportunities, technological innovations and tools for financing renewable energy.

To learn more about the 2015 Renewable Energy Conference & Expo’s agenda, exhibitors, and sponsors you can visit the conference website as well as follow the hashtag #RE2015 and Renewable Energy Vermont’s Twitter handle @RE_Vermont for updates!

About Renewable Energy Vermont (REV)

REV is Vermont’s only non-profit, non-partisan renewable energy trade association working to reduce our dependence on fossil fuels and expanding the availability of renewable sources of energy throughout the state and region.

14 Sep 2015

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.