14 Sep 2015

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

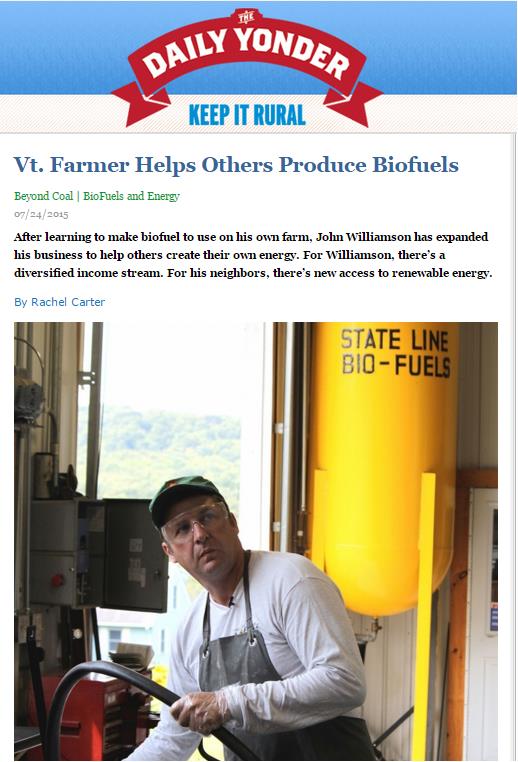

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

Farms open their doors to a public interested in learning more about where food comes from and supporting the local agricultural economy

Farmers across Vermont will throw open their barn doors and garden gates to welcome the public for a behind-the-scenes look at Vermont’s vibrant working landscape. Vermont’s first Open Farm Week will be held Monday, August 3 – Sunday, August 9, 2015.

Open Farm Week is a weeklong celebration of Vermont farms. Over 100 farms are participating, many of whom are not usually open to the public. Open Farm Week offers Vermonters and visitors alike educational opportunities to learn more about local food origins, authentic agritourism experiences, and the chance to build relationships with local farmers. Activities vary and may include milking cows and goats, harvesting vegetables, collecting eggs, tasting farm fresh food, scavenger hunts, hayrides, farm dinners, and live music.

Visit DigInVT for a map of participating farms by region. Many events are free and costs vary depending on what activities are offered. Everyone is invited to join the #VTOpenFarm conversations on social media. All participating farms, geographic location, and offerings are at www.DigInVT.com.

Farmers’ markets will also be a part of the Open Farm Week celebration as organizers planned the event to coincide with National Farmers’ Market Week – also the first week of August.

The first Vermont Buy Local Market on the Statehouse Lawn will be held during Open Farm Week on Tuesday, August 4th from 10am-1pm. The Vermont Agency of Agriculture, Food and Markets is organizing the first Statehouse farmers’ market in collaboration with the Capital City Farmers’ Market and NOFA-VT.

Building off of the success of NOFA-VT’s 2014 Open CSA Farm Day, Open Farm Week is a collaborative statewide agritourism project organized by members of the Vermont Farm to Plate Network including Intervale Center, Vermont Farm Tours, Neighboring Food Co-op Association, Vermont Agency of Agriculture, Vermont Fresh Network, Vermont Department of Tourism, Shelburne Farms and Farm-based Education, NOFA-VT, and City Market. Open Farm Week helps Vermont reach its statewide Farm to Plate food system plan goals to increase farm profitability, local food availability, and consumption of Vermont food products.

Vermont Open Farm Week is made possible by the generous support of Premiere Sponsor: City Market/Onion River Coop as well as the Vermont Department of Tourism and Marketing; Vermont Agency of Agriculture, Food and Markets, Localvore Today and Woodchuck Hard Cider.

13 Jul 2015

Making Biofuel

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

14 Apr 2014

Farm Fresh Fuel 2014

This guest post was contributed by Hannah Harwood and Dr. Heather Darby at UVM Extension Northwest Crops and Soils Program.

Travel Route 2 through Grand Isle County in early August this year and the rolling yellow fields along the roads will undoubtedly catch your eye. Sunflowers will be in bloom and, more than likely, tourists will be snapping photos. For the second year, growers throughout the county will be participating in a project that supports a small community of individuals who will be producing their own biofuels.

The Farm Fresh Fuel Project—created by UVM Extension’s Northwest Crops & Soils Program and the Vermont Bioenergy Initiative (VBI)—began in 2012 with about a dozen interested growers and 69 acres of sunflowers planted in the islands. Grand Isle County was chosen because it is a agriculturally-diverse community with some existing resources and experience in oilseed production. Participating growers, who signed up in each town in the county in 2012, ranged from seasoned dairy farmers to homesteaders trying their hand at crop production for the first time. All were grateful that the project was taking place in close proximity to technical assistance, equipment, and experienced growers.

That’s the whole idea of the Farm Fresh Fuel Project: developing a small community of individuals who can produce biofuels from the seed to the tank, in a place where the resources already exist to help along the way. Farm Fresh Fuel serves as a sort of small case study for alternative crops and small-scale biofuel production. If all Grand Isle County farmers integrated some amount of biodiesel into their operation, the county could be the first in the nation to have all of its agricultural producers using alternative energy.

Growers who want to participate in the project are responsible for providing the land, meeting fertility requirements, and arranging for planting, cultivation and harvest. In exchange, UVM Extension provides soil tests and interpretation, sunflower seed, technical crop production assistance, and in-season monitoring and insect scouting. After harvest, growers have the option of getting the seed processed at Borderview Farm in Alburgh, a facility with the on-site capacity to clean, dry, and press seed, as well as process raw oil into biodiesel.

Farm operator Roger Rainville and UVM Extension agronomist Heather Darby watch the sunflower seed flow out of the combine on West Shore Road in Alburgh, 2012. Credit: Hannah Harwood.

In 2012, the average sunflower seed yield was approximately 1400 lbs per acre, though the success of individual fields ranged drastically from one to the next. The most problematic obstacles for Grand Isle producers were birds and weeds, both of which are concerns for almost every oilseed grower in the Northeast. Overall, 28.3 tons of seed were harvested from the county, and Roger and Natasha Rainville at Borderview Farm pressed 2,750 gallons of oil for participating growers, enough to make 2150 gallons of biofuel. When the oil was pressed, what was left was 15.9 tons of sunflower meal—which some participants used to feed livestock or fertilize their vegetables, and some sold to other farmers in the county. Overall, there was a buzz of excitement about these new value-added products—oil, meal, and/or fuel—being produced right in the county.

Though there was increasing interest and an abundance of good intention in 2013, weather conditions in May and June (namely 6.9” of rain above standard 30-year averages) prevented most anticipated fields from being planted on time or at all. The fields that were successfully seeded had decent yields, but the project in general was delayed for a year, giving growers, processors, and weathermen a chance to regroup.

UVM Extension and VBI are excited to facilitate this project again in 2014, with renewed interest from 2012 growers as well as interest from farmers and landowners new to Farm Fresh Fuel. After hosting an informational meeting on March 27 and gauging interest, UVM Extension estimates that at least eight growers will participate this year, putting approximately 60 acres into oilseed crop production for fuel, feed, and fertilizer that’s grown right in their backyard. If the weather cooperates, planters will start rolling through fields in May, and little green sunflower shoots will be visible from the road by June.

21 Mar 2014

Local Production for Local Use: A Case Study

Prepared by Sarah Galbraith, Vermont Bioenergy Initiative Program Manager, VSJF

Highlights: Cost of biodiesel production = $2.29 per gallon ● Seed meal used as a co-product for livestock feed or crop fertilizer ● Central processing facility and shared equipment use maximizes efficiency for neighboring farms

Roger Rainville’s dairy-turned-energy farm in Grand Isle County is a place where area dairy farmers, organic growers, and landowners have made biodiesel from their own locally-grown sunflower seeds.

Roger Rainville with BioPro 190 automated biodiesel processor at Borderview Farm. Photo: Vermont Bioenergy Initiative

In 2008, when diesel prices rose from $4 to $5 per gallon, Rainville began experimenting with farm-scale biodiesel production. With guidance from University of Vermont (UVM) Extension and grant funding from Vermont Sustainable Jobs Fund’s Vermont Bioenergy Initiative, Rainville began planting sunflowers on a portion of his 214 acres and installing biodiesel processing equipment. Oilseed sunflowers (as opposed to confectionary sunflowers that are grown for eating) are the most popular oilseed crop in Vermont, with hundreds of acres planted statewide. The crop is grown in rotation with grains and grasses and yields high quantities of oil.

Harvesting, Cleaning, and Pressing

Following harvest with a combine, a seed cleaner and grain dryer are used to prepare the seeds for storage in a 200-ton grain bin prior to processing. A flex auger system moves the seeds from the storage bin into hoppers on each press, and screw augers push the seed through a narrow dye at the front of the press. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The oil can then be used as culinary oil for cooking or further refined into biodiesel. The leftover seed meal is used for livestock feed, fuel for pellet stoves, or fertilizer for crops.

Biodiesel Processing

The small-scale biodiesel production facility at Borderview Farm is an 800 square foot insulated and heated building (the space does not need to be heated, but the oil should be stored where it will not freeze) that houses an oil press, a BioPro 190 automated biodiesel processor, a methanol recovery system, and a set of dry-wash columns for cleaning the fuel. The clean oil at the top of each settling tank is added to the BioPro 190 processor along with lye, methanol, and sulfuric acid. The automated processor runs through several stages of processing in about 48 hours (esterification, transesterification, settling, washing, and drying), with one break after 24 hours to remove the glycerin byproduct. Safety equipment in the processing facility includes personal protective equipment like aprons, gloves, eye protection, a ventilation system, gas detectors, and spill containment materials. At Borderview Farm a set of standard operating procedures hangs on the wall and blank check-sheets are in a binder to make the process easy to repeat. The finished biodiesel is stored in 250 gallon pallet tanks making distribution to different farms easier. The installed capacity of the facility can process 100 tons of seeds from 138 acres of sunflowers per year, yielding 10,500 gallons of biodiesel and 64 tons of sunflower meal (assuming the state average yield of 1,500 pounds sunflower seeds per acre and operation of 24 hours per day for 260 days per year).

Rainville switched from purchasing diesel for five tractors and one truck to making his own biodiesel. He wanted to be independent of imported fuel, and liked creating a new way for farmers to diversify. “Using land for making biodiesel is not the most economical option compared to some other crops, but it’s about creating opportunities to try something different,” says Rainville.

Sharing Infrastructure Through the Farm Fresh Fuel Project

In 2012 a group of ten farmers working in cooperation with Rainville and UVM Extension—called the Farm Fresh Fuel project—grew 90 acres of sunflowers for development of biodiesel. Cooperating farmers were required to plant, fertilize, weed, and harvest the sunflower crop. Farmers worked to share equipment to accomplish this task. The seed was brought to Rainville for conversion into biodiesel. Rainville did the harvesting for all farms, bringing about 56,721 pounds of seed to Borderview Farm.

Seeds from the ten growers yielded about 3,000 gallons of biodiesel and about 20 tons of meal for livestock feed. The biodiesel and meal were then redistributed to the growers based on the relative volume of sunflower seeds they contributed. One participating dairy farm, Sunset Lake Farms, is using the biodiesel to heat office space, the milking parlor, and water for cleaning and sanitizing equipment, and fed the meal to milking cows at a rate of 3 pounds per day, saving about $3,000 on fuel and feed costs.

Rainville’s annual biodiesel use has ranged from 500 to 3,000 gallons per year. At current prices (over $4 per gallon for diesel and $2.29 per produced gallon of biodiesel) biodiesel has saved him from $500 to $4,000 per year in fuel costs. He also emphasizes energy independence as an added benefit. Plus, any growers that also raise livestock can use the meal, which is leftover after the oil is extracted, as part of their feed rations. Rainville recommends talking with an animal nutritionist to blend this into feed at the right ratio, since sunflower meal has a high fat content.

When asked what advice Rainville would give others who want to make their own biodiesel, he says, “Ask questions, ask questions, ask questions. And ask them again!”

Learn more about energy efficiency and renewable energy in the Energy section of the Vermont Food System Atlas.

Monday, March 3, 2014 at the Sheraton Hotel and Conference Center in Burlington, VT. Join us to learn from growers, processors and researchers about their experience with oilseed crops like sunflower, canola, soybeans and flax. Discuss how these oilseeds can add value to farms in the form of feed, fuel, soil amendments and culinary oil. View the workshop brochure or the detailed agenda for more information. Visit www.uvm.edu/extension/oilseed meeting to register.

19 Sep 2013

State Line Farm

Feedstock: Sunflowers, canola, mustard

Feedstock: Sunflowers, canola, mustard

Fuel: Biodiesel

Energy Output: Power (for farm machinery)

Services: Oilseed and Grain Grower, Oil milling, Fuel Processing, Feed Supply

Owner: John Williamson

Location: Shaftsbury, Vermont; Bennington County

On the forefront of oilseed crop growing in a northeastern climate, State Line Biofuels is Vermont’s first on-farm facility making biodiesel made from oilseed crops grown on-site and from neighboring farms.

The Williamson family has owned State Line Farm in southwest Vermont alongside the border of New York since 1936. For many years, State Line was run as a traditional dairy farm, but falling milk prices caused them to sell the herd and look towards diversifying the farm’s operations.

John and his family currently produce maple syrup, honey, sorghum syrup and hay for sale in local markets. Since 2004, State Line Farm has also experimented with sunflower, canola, mustard, and flax varieties in an effort to fuel their farm with biodiesel.

Read More

17 Sep 2013

North Hardwick Organic Dairy

Feedstock: Sunflowers, certified organic

Feedstock: Sunflowers, certified organic

Fuel: Biodiesel

Co-products: High-protein sunflower meal as feed ingredient

Energy Output: Power (for farm machinery)

Services: Oilseed Grower, Oil milling, Fuel Processing, Feed Supply

Owner: Nick and Taylor Meyer

Location: Hardwick, Vermont

The Meyer family has owned and operated their dairy on a 327-acre farm in Hardwick, Vermont since 1978. In 2003, when the younger Meyer boys took over the farm where they grew up, they transitioned to organic production. Today, Nick and Taylor produce some of the highest quality milk in the state of Vermont, winning numerous awards and gaining notoriety for their sustainable and innovative approach.

That approach has included efforts to reduce overhead costs by making the farm as self-sufficient as possible. A Bergy Wind Turbine was erected in 2007 to provide some of the farm’s electricity and Andrew began making biodiesel from waste vegetable oil in 2008. All the tractors on the farm run on B50 (50% biodiesel & 50% petrodiesel) for the summer and the furnace runs on B15 for the winter months.

“I want to produce everything the farm needs, without buying out (off the farm)” Nick Meyer explains. North Hardwick Dairy (NHD) uses 4,000 gallons of diesel each year (2,000 gallons of diesel for off- road equipment and 2,000 gallons in their furnace).

Read More

A roadside sign informs passerby of the Farm Fresh Fuel project in Grand Isle County, Vermont. Photo credit: VSJF

A small revolution is happening in Grand Isle County, a declaration of fuel independence: In 2012, ten farmers and landowners tried their hand at growing sunflowers to have the oil made into biodiesel to fuel farm equipment or heat their homes.

Many farmers want to diversify their operation, control and lower fuel costs, and become more self-sufficient. Additionally, locally-grown renewable energy will support the agriculture economy. In Grand Isle County, growing their own biodiesel can save farmers more than $2.00 per gallon, according to a new study released by the Vermont Sustainable Jobs Fund (See the report, Vermont On-Farm Oilseed Enterprises: Production Capacity and Breakeven Economics). Emerging feedstocks and new technology takes know-how, and the Vermont Bioenergy Initiative (VBI) at Vermont Sustainable Jobs Fund is taking steps to overcome barriers to energy self-sufficiency on the farm.

With funding from the U.S. Department of Energy, Borderview Farm staff and UVM Extension researchers guided the planting, tending, and harvesting of more than 60 acres of sunflowers in the 2012 growing season for the Grand Isle Farm Fresh Fuels Project. Each farmer planted two to ten acres of sunflowers, growing more than 30 tons of sunflower seeds. The seeds will be pressed into 3,000 gallons of renewable, low-emission biodiesel and 26 tons of oilseed meal to feed livestock or use as pellet fuel.

For the UVM researchers, coordinating the project, overcoming some of the logistical challenges, and shepherding a successful crop of sunflowers into the storage bin at Roger Rainville’s farm was all part of the job. The lessons learned this year in Grand Isle County also contribute to a growing body of knowledge that is helping farmers in other regions put more acres under oilseed production and save money on their fuel bills.

To learn more about the Farm Fresh Fuel project, visit the UVM website and the Oilseeds section of this website.