David Marchant and Jane Sorensen of River Berry Farm—an organic vegetable and fruit producer in Fairfax—were early adopters of biomass heating when they installed a corn and pellet furnace in one of their greenhouses in 2008. The furnace required manual lighting and was snuffed out often when strong winds blew, and did not produce reasonable heat. “I kept thinking, there has got to be a better option,” recalls David, “It was a real labor burden, and you couldn’t count on it.”

David Marchant and Jane Sorensen of River Berry Farm—an organic vegetable and fruit producer in Fairfax—were early adopters of biomass heating when they installed a corn and pellet furnace in one of their greenhouses in 2008. The furnace required manual lighting and was snuffed out often when strong winds blew, and did not produce reasonable heat. “I kept thinking, there has got to be a better option,” recalls David, “It was a real labor burden, and you couldn’t count on it.”

Based on their early experiences and bolstered by a commitment to long-term sustainability and reduced fossil fuel dependence, River Berry Farm opted to host a biomass heating demonstration project. This time, they opted for a higher-rated boiler rather than a furnace. Boilers produce hot water, rather than hot air, which allows more options for distributing the heat. The new system also had an automated propane ignition system.

The biomass heating demonstration was part of a UVM Extension project aimed at trialing several furnaces in agricultural heating applications with funding support provided by the High Meadows Fund. According to Chris Callahan, Ag Engineer with UVM Extension Agricultural Engineering Program who assisted with some of the design and performance assessment, “The main lessons learned from these early installations were to buy high quality fuel, seek improved automatic ignition controls, invest in a good chimney and install it well, and know the actual heat output rating of the unit.”

Modern biomass heating appliances generally include a fuel storage bin, an auger for feeding fuel to the appliance, the appliance itself (boiler or furnace) with an ignition system, a combustion chamber, a heat exchanger, and a heat distribution system. They also incorporate some means of controlling combustion, fuel feed rate, and air flow and often include emissions control measures and automated ash removal.

The selected boiler was a Central Boiler Maxim 250 with a 250,000 BTU/hr input rating, efficiency of 87.8%, and EPA Phase II Hydronic Heater qualification. “The boiler makes hot water which we can use in multiple greenhouses by plumbing it to them in insulated PEX piping. Once in the greenhouse, we convert to hot air with a hot water fan coil, put it in the ground for root-zone heating or on the benches in our mat-heating system for starts,” says Marchant. “I like it. I keep trying to find something wrong with it, but I can’t. The payback period is a bit longer due to higher initial costs, but you have to expect that.”

The basic system cost was approximately $13,000 for the boiler, bin, pad, and plumbing to a hot water fan coil. The other heat distribution systems included in-ground PEX, heat exchange, and plumbing for a bench heat system and added approximately another $5,000. The system is more automated and reliable than the earlier furnace was, but the higher initial costs and the fact that the system is only used 3 months out of the year do prolong the payback period to about 12 years when compared with a propane furnace. If the system was used for 6 (space heating) or even 12 months (wash water, pasteurization) of the year the payback would be halved or quartered, respectively.

“In addition to the financial payback, the carbon emissions avoidance is also of interest to many people,” says Callahan, “In River Berry Farm’s case, the Maxim is helping them avoid 5,910 pounds of net CO2 emissions per year which is about equivalent to 5,000 miles car travel or the CO2 sequestered by half an acre of pine forest.”

Learn more about UVM Extension’s Agricultural Engineering Program at.

This story was originally released in a series of energy case studies showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production—all of which are components for helping Vermont reach the renewable energy and environmental impact goals of the Farm to Plate Strategic Plan. Learn more at www.vtfarmtoplate.com.

14 Sep 2015

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

07 Sep 2015

Weekly Energy Action Seminars at UVM

Beginning Monday the 14th of September, and reoccurring each week thereafter, an Energy Action Seminar Series aims to explore energy transitions in Vermont, the United States and the rest of the World. Sponsored by the University of Vermont’s Clean Energy Fund, Community Development & Applied Economic program, and the Environmental Program this series will be held from 4:00-05:20 pm in Lafayette Hall Room 108* at the University of Vermont. This series featuring world-class speakers on policy options, political controversy, costs and benefits, activism, and jobs is free and open to the public.

While there is already an extensive line-up of speakers, the most high profile speaker to stand out on the list is former Vice President Al Gore. Gore will draw on his years of climate advocacy for his discourse entitled “The Climate Crisis and The Case for Hope.” When delivering this discourse, Gore aims to address three big questions on the climate crisis: Do we need to change? Can we? And will we? The resounding answer to first two questions of course is a loud YES, but third one most likely cannot be answered in certain terms, and hopefully this where Gore can leave us all with “a case for hope.” NOTE: There is a slight deviation of schedule; this seminar will be on Tuesday, October 6th at 10:15 AM in Ira Allen Chapel.

In addition to Al Gore, numerous other leaders from near and afar will attend and speak during the duration of this series. One such visitor on September 21st, Professor Miranda Schreurs of Free University of Berlin and Director of their Environmental Policy Cente,r stands to bring a plethora of insight from her experience in Germany’s renewable energy revolution. In her time with the Environmental Policy Research Center, Professor Schreurs was on the frontlines of the interdisciplinary collaboration of university researchers necessary for Germany to meet it’s ambitious goal of running almost their entire economy on renewable energy by the year 2050. Germany’s goal is very similar to Vermont’s 2050 goal, and the potential for collaboration and to learn from one another through this event are boundless.

Another great guest speaker will come from Washington, all the way across the US,. Yoram Bauman, more commonly known “Stand-Up Economist,” uses a unique combination of witty comedic talent along with his PhD in Environmental Economics to help an audience explore climate change in an economic context. Yoram’s seminar exploring carbon taxing on October 10th will fall just a couple of days after he serves as the keynote speaker and sits on a carbon pricing panel at the 15th Annual Renewable Energy Conference & Expo in Burlignton, VT. His fresh and recent insight into Vermont’s existing carbon pricing discussion mixed with his existing expertise, and sense of humor will make this event worth not missing.

Additionally, many Vermont energy leaders will be speaking at theses weekly seminars including Representative Tony Klein Chair of House Energy and Natural Resources, Asa Hopkins Director of Planning for the Department of Public Service, Gabrielle Stebbins Director of Renewable Energy Vermont, and Mary Powell of Green Mountain Power. Each of these speakers, as well as the entities they represent, have proven themselves leaders in the Vermont energy landscape through their involvement in recent energy legislation, advocacy, and innovation.

| 9/14 | Energy Transitions | Jennie Stephens, Blittersdorf Professor of Sustainability Science & Policy, University of Vermont |

| 9/21 | Going Green: The German Energy Transition | Miranda Schreurs, Professor, Free University of Berlin Director, Environmental Policy Center |

| 9/28 | The Vermont Energy Transition | Tony Klein, Chair: House Energy and Natural Resources, Asa Hopkins, Director of Planning, Department of Public Service. Gabrielle Stebbins, Director, Renewable Energy Vermont |

| 10/5 | Student Alumni: Making a Difference in the World | Panel: Recent UVM grads in energy-related fields |

| 10/6* | The Climate Crisis and The Case for Hope | Al Gore, former Vice-President, United States |

| 10/12 | Carbon Taxes: Why We Need Them | Yoram Bauman, The world’s only “stand-up” Economist |

| 10/19 | Challenging the Car: Creating places where biking is safe & easy | Steve Clark, League of American Bicyclists, Community Organizer |

| 10/26 | Vermont’s Energy Company of the Future: A Customer Driven Energy Transformation | Mary Powell, President & CEO, Green Mountain Power |

| 11/2 | “The War on Coal:” Big Fossils’ Response to Divestment | Jen Schneider, Political Science Dept. Boise State University |

| 11/9 | The Transportation Transition: Complete Streets | Roger Millar, Director, SmartGrowth America |

| 11/16 | Energy Transitions in the Developing world: South Africa Settlements | Steve McCauley, Worcester Polytechnic Institute |

| 11/30 | Design Matters: Building Green | Rolf Keilman, Partner, Truex-Cullins, Vermont |

* Al Gore presentation is in the Ira Allen Chapel, special time, 10:15 a.m. Oct. 6

For more information contact

Fred Hall fhall@uvm.edu

Roison Low rlow@uvm.edu

Richard Watts rwatts@uvm.edu

The Vermont Bioenergy Initiative connects diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. Explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

Video

A series of informative educational showcase a range of biofuel possibilities; from research and crop farming to feedstocks and fuel. The videos were developed by the Vermont Sustainable Jobs Fund, UVM Extension researchers, KSE Partners, and the Vermont Bioenergy Initiative grantees.

Calculators

Two calculators, developed by UVM Extension, help connect potential costs and profits associated with oilseed production:

- Grass Biomass Production and Harvest Cost Estimator

- Vermont Oilseed Crop Production Cost and Profit Calculator

Course Work

- Biomass to Biofuels, University of Vermont: This semester-long course covers liquid and solid biofuels, biogas and bio-electricity, and environmental, social and economic issue related to biofuels. The course includes guest lecturers and field days. Available for variable credits.

- Biomass to Biofuels, Vermont Technical College: The development of this course and associated materials led to an online repository of resources for the classroom covering biomass to biofuels.

- Digester Operations Master Certificate, Vermont Technical College: a twelve week program designed for participants to work directly with operations staff of Vermont Tech’s anaerobic digester and come away with understanding of the mechanics and operations of a digester system, as well as other areas such as permitting, regulatory compliance and record keeping.

- Alternative Fuel Vehicles: Biodiesel, part of the Green Trainings series at Vermont Technical College: This 2-day course covers engine systems, biodiesel blends and biodiesel production, including a demonstration of fuel-making equipment.

- Biofuels Course at Yestermorrow Design/Build School, part of the Green Trainings series at Vermont Technical College: This weekend workshop enables students to begin replacing fossil fuels with biofuels, such as adapting engines to run on straight vegetable oil. 1 credit.

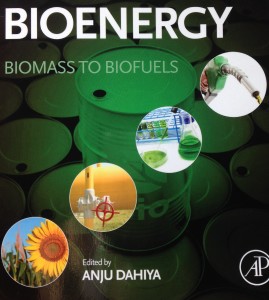

Textbook

Bioenergy: Biomass to Biofuels; is an innovative new textbook that provides insight into the potential and current advances and benefits of biofuel. Contributions include an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Reports

A variety of reports are available which cover a range of topics including seed preparation and storage:

- Institute for Energy and the Environment at Vermont Law School.Legal & Regulatory Review of On-farm Biodiesel Production. 2015.

- Chris Callahan and Netaka White,Vermont On-Farm Oilseed Enterprises: Production Capacity and Break-even Economics. July 2013.

- Nell Campbell, Local Production for Local Use to Supply a Portion of Vermont’s Energy Needs.May 2009.

- Emily J. Stebbins. Technical and Economic Feasibility of Biodiesel Production in Vermont: Evidence From a Farm-Scale Study and a Commercial-Scale Simulation Analysis. May 2009.

- Christopher W. Callahan,A Feasibility Analysis of a Mobile Unit for Processing Oilseed Crops and Producing Biodiesel in Vermont. December 2008.

- Emily Stebbins, The Market Potential of Farm-Scale Oilseed Crop Products in Vermont. February 2008. (See also the Executive Summary)

- John Williamson & Tanner Williamson – State Line Biofuels, LLP, Chris Callahan – Callahan Engineering, PLLC, Feasibility Analysis:_Solar Seed Dryer and Storage Bin at State Line Farm, Bennington, VT. October 2008

- Christopher W. Callahan, A Feasibility Study of a Mobile Unit for Processing Oilseed Crops and Producing Biodiesel in Vermont. December 2008

- Kenneth Mulder, Ph.D., Galen Wilkerson, Emily J. Stebbins.Homegrown Fuel: Economic Feasibility of Commercial-Scale Biodiesel Production in Vermont. September 2007.

- The Vermont Biodiesel Project: Building Demand in the Biofuels Sector – Final Report. October 2006. (See also theExecutive Summary)

- Vermont Department of Buildings and General Services, Vermont Biodiesel Pilot Project: Emissions Testing of Biodiesel Blends With #6 Fuel Oil At the Waterbury State Office Complex – Final Report. September 2006.

- Laboratory and Field Testing of Biodiesel in Residential Space Heating Equipment – Final Report. August 2006.

- Vermont Biodiesel Supply Chain Survey – Final Report. April 2006.

- Wilson Engineering,Grass Energy in Vermont and the Northeast, May 2014.

Technical Advice

Connect directly with the Vermont Bioenergy Initiative’s technical assistance providers:

Oilseeds for Biofuel

- Heather Darby, Agronomic and Soils Specialist

- University of Vermont Extension, Northwest Crops and Soils Team

- (802) 524-6501

- darby@uvm.edu

- Chris Callahan, PE, Agricultural Engineer

- University of Vermont Extension

- (802) 773-3349

- callahan@uvm.edu

Grass for Heating Fuel

- Sidney Bosworth, Extension Professor

- University of Vermont College of Agriculture and Life Sciences

- (802) 656-0478

- bosworth@uvm.edu

Algae for Biodiesel

- Anju Dahiya, Instructor and Principal

- University of Vermont and GSR Solutions

- (802) 310-1936

- adahiya@uvm.edu

27 Jul 2015

Summit on Creating Prosperity and Opportunity Confronting Climate Change – Looking Back and Looking Forward

The Summit on Creating Prosperity and Opportunity Confronting Climate Change brought together over 400 innovative business, non‐profit, and community leaders, elected officials, public policy advocates, students, and interested residents to begin to frame policy and investment strategies to advance the development of the Vermont Climate Economy. Summit participants developed a list of key practical actions to serve as a launching point for the Vermont Climate Change Economy Council (VCCEC), a group charged with a one year mission to develop a structured plan with practical actions to reduce carbon emissions and stimulate green economic development in Vermont. The Council will build a set of public/private strategies designed to promote economic opportunity, innovative business development, investment, and job creation in Vermont.

The Summit on Creating Prosperity and Opportunity Confronting Climate Change brought together over 400 innovative business, non‐profit, and community leaders, elected officials, public policy advocates, students, and interested residents to begin to frame policy and investment strategies to advance the development of the Vermont Climate Economy. Summit participants developed a list of key practical actions to serve as a launching point for the Vermont Climate Change Economy Council (VCCEC), a group charged with a one year mission to develop a structured plan with practical actions to reduce carbon emissions and stimulate green economic development in Vermont. The Council will build a set of public/private strategies designed to promote economic opportunity, innovative business development, investment, and job creation in Vermont.

Over the course of 2015, VCCEC will evaluate findings, key ideas and suggested action steps derived from the Summit, lead regional public forums, evaluate and summarize research findings, interview key stakeholder groups, and consider model economic development strategies from other state and countries. During 2015, the group will develop a strategic platform of recommendations for action, and report to the Vermont legislature, the Governor of Vermont and the public in January 2016. The Vermont Council on Rural Development (VCRD) will provide support to their work and then help promote the platform of action that comes from its deliberants. Goals of the Vermont Climate Change Economy Council are to:

- Identify opportunities created by climate change to strengthen Vermont’s economy through strategies advancing key business clusters and economic sectors.

- Build an increased sense of unity in Vermont around policies to confront and mitigate the impact of climate change and to advance economic opportunities and solutions that respond to climate change.

- Build a public information campaign to celebrate innovation and Vermont’s green business leadership; internally and externally marketing to build the Vermont brand as an economic/environmental problem solver.

- Expand Vermont’s economic brand around climate change solutions to retain and attract youth and creative entrepreneurs to locate throughout the state.

Vermont businesses and nonprofits are addressing climate change – both its challenges and opportunities. Their creative solutions are a growing part of our state’s economy. What are your experiences? Do you have ideas about how Vermont can grow jobs and nurture innovative business development in sectors ranging from clean energy, to recycling, transportation systems, and thermal efficiency?

Jo![Regional_Forum_Flyer5_15_statewide[1]](https://vermontbioenergy.com/wp-content/uploads/2015/07/Regional_Forum_Flyer5_15_statewide1-150x150.jpg) in the Vermont Council on Rural Development and local business leaders at a forum on “What’s Next for Vermont’s Climate Change Economy?” Forums will take place at 7:00pm at the Paramount in Rutland (Aug 26), the Latchis Hotel in Brattleboro (Oct 6), and City Hall in Burlington (Oct 29). Come to the forum(s) most convenient for you.

in the Vermont Council on Rural Development and local business leaders at a forum on “What’s Next for Vermont’s Climate Change Economy?” Forums will take place at 7:00pm at the Paramount in Rutland (Aug 26), the Latchis Hotel in Brattleboro (Oct 6), and City Hall in Burlington (Oct 29). Come to the forum(s) most convenient for you.

These forums are the next step for public input to the Vermont Climate Change Economy Council, a group working to develop a practical plan to reduce carbon emissions and stimulate economic development in Vermont. To learn more about the forums and the Council visit VCRD’s website at vtrural.org, download the event flyer (pdf).

For more information about the results of the summit, Click HERE to read the report and follow the hashtag #VTClimateEconomy and Vermont Council on Rural Development on Twitter at @VTRuralDev for more updates!

Farms open their doors to a public interested in learning more about where food comes from and supporting the local agricultural economy

Farmers across Vermont will throw open their barn doors and garden gates to welcome the public for a behind-the-scenes look at Vermont’s vibrant working landscape. Vermont’s first Open Farm Week will be held Monday, August 3 – Sunday, August 9, 2015.

Open Farm Week is a weeklong celebration of Vermont farms. Over 100 farms are participating, many of whom are not usually open to the public. Open Farm Week offers Vermonters and visitors alike educational opportunities to learn more about local food origins, authentic agritourism experiences, and the chance to build relationships with local farmers. Activities vary and may include milking cows and goats, harvesting vegetables, collecting eggs, tasting farm fresh food, scavenger hunts, hayrides, farm dinners, and live music.

Visit DigInVT for a map of participating farms by region. Many events are free and costs vary depending on what activities are offered. Everyone is invited to join the #VTOpenFarm conversations on social media. All participating farms, geographic location, and offerings are at www.DigInVT.com.

Farmers’ markets will also be a part of the Open Farm Week celebration as organizers planned the event to coincide with National Farmers’ Market Week – also the first week of August.

The first Vermont Buy Local Market on the Statehouse Lawn will be held during Open Farm Week on Tuesday, August 4th from 10am-1pm. The Vermont Agency of Agriculture, Food and Markets is organizing the first Statehouse farmers’ market in collaboration with the Capital City Farmers’ Market and NOFA-VT.

Building off of the success of NOFA-VT’s 2014 Open CSA Farm Day, Open Farm Week is a collaborative statewide agritourism project organized by members of the Vermont Farm to Plate Network including Intervale Center, Vermont Farm Tours, Neighboring Food Co-op Association, Vermont Agency of Agriculture, Vermont Fresh Network, Vermont Department of Tourism, Shelburne Farms and Farm-based Education, NOFA-VT, and City Market. Open Farm Week helps Vermont reach its statewide Farm to Plate food system plan goals to increase farm profitability, local food availability, and consumption of Vermont food products.

Vermont Open Farm Week is made possible by the generous support of Premiere Sponsor: City Market/Onion River Coop as well as the Vermont Department of Tourism and Marketing; Vermont Agency of Agriculture, Food and Markets, Localvore Today and Woodchuck Hard Cider.

13 Jul 2015

Making Biofuel

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

Algae produces more than half of the oxygen on the planet, while consuming vast amounts of heat-trapping carbon dioxide and taking up nutrients like nitrogen and phosphorous to make biomass and energy. The lipids, or oil, that algae produce can be extracted and processed into renewable fuels such as biodiesel. Algae are an excellent source of oil for making biodiesel, which could displace substantial volumes of petro-diesel for heating and transportation. Microalgae reproduce rapidly, and they grow on non-agricultural land, so they do not compete with food, feed, or fiber production.

The keys to commercializing algae for biofuel production include identifying and cultivating native species, optimizing growing conditions in natural and artificial environments and the efficient harvest and oil extraction of algal biomass. At the forefront of this algae biofuel research is Dr. Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. Dr. Dahiya has been searching for high lipid algae strains, and scaling those up to a level that could be available for commercial use, especially for biofuels.

“At GSR Solutions, we are looking at producing algae not just for biofuels, but combining it with waste water treatment and to produce other valued byproducts as well. This is very significant, because this would make algae production cost-effective. This would also help in nutrient recovery,” says Dahiya.

innovative new textbook that provides insight into the potential and current advances and benefits of biofuel

Some of the findings and knowledge afforded by Dr. Dahiya’s research are available in the new introductory textbook, Bioenergy: Biomass to Biofuels, which was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories. Dr. Dahiya will also be using this textbook as the basis for a University of Vermont Bioenergy Course offered for the 2015 fall semester.

In the below video, Vermont researchers and entrepreneurs demonstrate their innovations in algae to biofuel research and development.

For more algae bioenergy resources see the visit the Algae section of the Vermont Bioenergy Website.

Learn more about the mentioned UVM Bioenergy Course visit the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

For more information on the introductory textbook Bioenery; Biomass to Biofuels see our write up on the book here!

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

In order to meet the goals set by Vermont’s comprehensive energy plan for Vermont to produce 90 percent of the state’s energy needs from renewables by 2050 and reduce Vermont’s greenhouse gas emissions by 50 percent from a 1990 baseline, Vermont farmers will have an important role to play. As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more important prompting statewide energy and agriculture collaborations. In the following episodes of Across the Fence, UVM Extension agricultural engineer and Vermont Bioenergy Initiative biofuels consultant, Chris Callahan, shares two stories about Vermont farmers who are rethinking their on-farm energy. In both examples UVM extension is able to work with the farmers to help make cleaner, renewable on-farm energy sources a practical solution that saves money and results in greenhouse gas reductions.

Learn more in a series of on-farm energy case studies produced by Vermont’s Farm to Plate Initiative.