19 Oct 2015

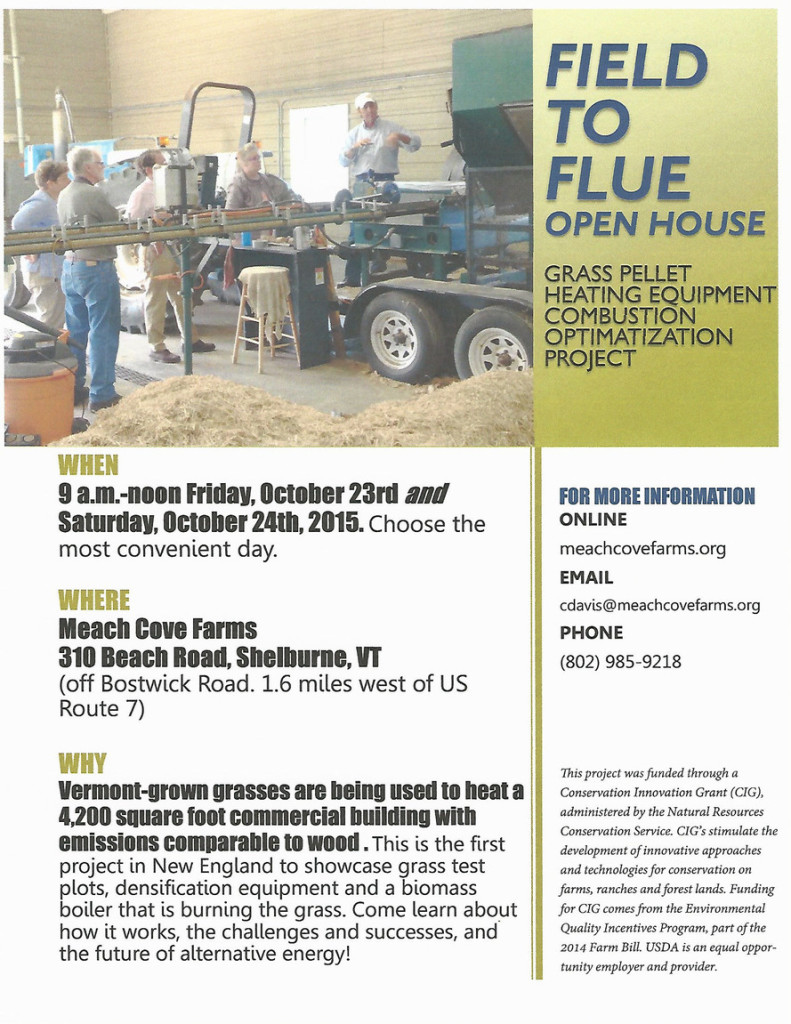

Field to Flue Open House at Meach Cove Farms

Vermont-grown grasses are being used to heat the Biomass Building – a 4,200 square foot commercial building at Meach Cove Farms in Shelburne. Local residents, community leaders, and renewable energy enthusiasts are invited to visit Meach Cove Farms Friday, October 23 – Saturday, October 24 for an Open House to learn how grass pellets are generating heat in a biomass boiler – an emerging source of bioenergy in Vermont.

Meach Cove Farms is a 1,000-acre certified organic farm primarily growing soy beans, wheat, rye, and corn as well as wine grapes, woodlands, and switchgrass trial plots for use in grass energy production. The Open House will offer a complete demonstration of the Grass Pellet Heating Equipment Combustion Optimization project – the first project in New England to showcase grass test plots, densification equipment, and an EvoWorld biomass boiler that burns the grass.

Meach Cove Farms began collaborating with Dr. Sidney Bosworth of the University of Vermont College of Agriculture and Life Sciences and the Vermont Bioenergy Initiative in 2009 to assess the potential of different species of grass as solid biofuel for heating applications.

In September 2011 Meach Cove Farms was awarded an USDA Natural Resources Conservation Service Conservation Innovation Grant to research the feasibility of Vermont grown grass pellets and heating equipment potential as an emerging renewable energy source in Vermont. The biomass boiler being featured at the Open House was funded through a Conservation Innovation Grant (CIG) administered by the Natural Resources Conservation Services.

IF YOU GO:

Meach Cove Farms is located at 310 Beach Road in Shelburne (off Bostwick Road, 1.6 miles west of Rte 7). The Open House runs from 9 am – 12 noon both Friday and Saturday, October 23-24. There is no cost and both days are open to the public. More info at www.meachcovefarms.org, 802-985-9218.

David Marchant and Jane Sorensen of River Berry Farm—an organic vegetable and fruit producer in Fairfax—were early adopters of biomass heating when they installed a corn and pellet furnace in one of their greenhouses in 2008. The furnace required manual lighting and was snuffed out often when strong winds blew, and did not produce reasonable heat. “I kept thinking, there has got to be a better option,” recalls David, “It was a real labor burden, and you couldn’t count on it.”

David Marchant and Jane Sorensen of River Berry Farm—an organic vegetable and fruit producer in Fairfax—were early adopters of biomass heating when they installed a corn and pellet furnace in one of their greenhouses in 2008. The furnace required manual lighting and was snuffed out often when strong winds blew, and did not produce reasonable heat. “I kept thinking, there has got to be a better option,” recalls David, “It was a real labor burden, and you couldn’t count on it.”

Based on their early experiences and bolstered by a commitment to long-term sustainability and reduced fossil fuel dependence, River Berry Farm opted to host a biomass heating demonstration project. This time, they opted for a higher-rated boiler rather than a furnace. Boilers produce hot water, rather than hot air, which allows more options for distributing the heat. The new system also had an automated propane ignition system.

The biomass heating demonstration was part of a UVM Extension project aimed at trialing several furnaces in agricultural heating applications with funding support provided by the High Meadows Fund. According to Chris Callahan, Ag Engineer with UVM Extension Agricultural Engineering Program who assisted with some of the design and performance assessment, “The main lessons learned from these early installations were to buy high quality fuel, seek improved automatic ignition controls, invest in a good chimney and install it well, and know the actual heat output rating of the unit.”

Modern biomass heating appliances generally include a fuel storage bin, an auger for feeding fuel to the appliance, the appliance itself (boiler or furnace) with an ignition system, a combustion chamber, a heat exchanger, and a heat distribution system. They also incorporate some means of controlling combustion, fuel feed rate, and air flow and often include emissions control measures and automated ash removal.

The selected boiler was a Central Boiler Maxim 250 with a 250,000 BTU/hr input rating, efficiency of 87.8%, and EPA Phase II Hydronic Heater qualification. “The boiler makes hot water which we can use in multiple greenhouses by plumbing it to them in insulated PEX piping. Once in the greenhouse, we convert to hot air with a hot water fan coil, put it in the ground for root-zone heating or on the benches in our mat-heating system for starts,” says Marchant. “I like it. I keep trying to find something wrong with it, but I can’t. The payback period is a bit longer due to higher initial costs, but you have to expect that.”

The basic system cost was approximately $13,000 for the boiler, bin, pad, and plumbing to a hot water fan coil. The other heat distribution systems included in-ground PEX, heat exchange, and plumbing for a bench heat system and added approximately another $5,000. The system is more automated and reliable than the earlier furnace was, but the higher initial costs and the fact that the system is only used 3 months out of the year do prolong the payback period to about 12 years when compared with a propane furnace. If the system was used for 6 (space heating) or even 12 months (wash water, pasteurization) of the year the payback would be halved or quartered, respectively.

“In addition to the financial payback, the carbon emissions avoidance is also of interest to many people,” says Callahan, “In River Berry Farm’s case, the Maxim is helping them avoid 5,910 pounds of net CO2 emissions per year which is about equivalent to 5,000 miles car travel or the CO2 sequestered by half an acre of pine forest.”

Learn more about UVM Extension’s Agricultural Engineering Program at.

This story was originally released in a series of energy case studies showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production—all of which are components for helping Vermont reach the renewable energy and environmental impact goals of the Farm to Plate Strategic Plan. Learn more at www.vtfarmtoplate.com.

14 Sep 2015

Vermont Farmer Helps Others Produce Biofuel

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

The Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund, aims to foster the sustainable bioenergy through a local production for local use model, proven to work for Vermont. Since 2003 the program has allowed Vermont farms to ease their resilience on inconsistently priced, foreign fossil fuels and other agricultural inputs. This is accomplished by focusing on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass energy for heating, and algae production for biofuels and waste management.

Vermont Bioenergy Initiative grantees have shown just how much the addition of biomass feedstock can contribute to sustainable agriculture. As one of these grantees, John Williamson of Stateline Farm would put it, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is really a novel way to look of what he is doing on his North Bennington farm. John was featured in a recent story in Daily Yonder which outlined his work and how he has begun helping his Vermont neighbors find their path to this form of sustainable, renewable energy.

For more about John Williamson’s on-farm biodiesel production, watch this video of John in self-designed Biobarn. He and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Also, explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

07 Sep 2015

Weekly Energy Action Seminars at UVM

Beginning Monday the 14th of September, and reoccurring each week thereafter, an Energy Action Seminar Series aims to explore energy transitions in Vermont, the United States and the rest of the World. Sponsored by the University of Vermont’s Clean Energy Fund, Community Development & Applied Economic program, and the Environmental Program this series will be held from 4:00-05:20 pm in Lafayette Hall Room 108* at the University of Vermont. This series featuring world-class speakers on policy options, political controversy, costs and benefits, activism, and jobs is free and open to the public.

While there is already an extensive line-up of speakers, the most high profile speaker to stand out on the list is former Vice President Al Gore. Gore will draw on his years of climate advocacy for his discourse entitled “The Climate Crisis and The Case for Hope.” When delivering this discourse, Gore aims to address three big questions on the climate crisis: Do we need to change? Can we? And will we? The resounding answer to first two questions of course is a loud YES, but third one most likely cannot be answered in certain terms, and hopefully this where Gore can leave us all with “a case for hope.” NOTE: There is a slight deviation of schedule; this seminar will be on Tuesday, October 6th at 10:15 AM in Ira Allen Chapel.

In addition to Al Gore, numerous other leaders from near and afar will attend and speak during the duration of this series. One such visitor on September 21st, Professor Miranda Schreurs of Free University of Berlin and Director of their Environmental Policy Cente,r stands to bring a plethora of insight from her experience in Germany’s renewable energy revolution. In her time with the Environmental Policy Research Center, Professor Schreurs was on the frontlines of the interdisciplinary collaboration of university researchers necessary for Germany to meet it’s ambitious goal of running almost their entire economy on renewable energy by the year 2050. Germany’s goal is very similar to Vermont’s 2050 goal, and the potential for collaboration and to learn from one another through this event are boundless.

Another great guest speaker will come from Washington, all the way across the US,. Yoram Bauman, more commonly known “Stand-Up Economist,” uses a unique combination of witty comedic talent along with his PhD in Environmental Economics to help an audience explore climate change in an economic context. Yoram’s seminar exploring carbon taxing on October 10th will fall just a couple of days after he serves as the keynote speaker and sits on a carbon pricing panel at the 15th Annual Renewable Energy Conference & Expo in Burlignton, VT. His fresh and recent insight into Vermont’s existing carbon pricing discussion mixed with his existing expertise, and sense of humor will make this event worth not missing.

Additionally, many Vermont energy leaders will be speaking at theses weekly seminars including Representative Tony Klein Chair of House Energy and Natural Resources, Asa Hopkins Director of Planning for the Department of Public Service, Gabrielle Stebbins Director of Renewable Energy Vermont, and Mary Powell of Green Mountain Power. Each of these speakers, as well as the entities they represent, have proven themselves leaders in the Vermont energy landscape through their involvement in recent energy legislation, advocacy, and innovation.

| 9/14 | Energy Transitions | Jennie Stephens, Blittersdorf Professor of Sustainability Science & Policy, University of Vermont |

| 9/21 | Going Green: The German Energy Transition | Miranda Schreurs, Professor, Free University of Berlin Director, Environmental Policy Center |

| 9/28 | The Vermont Energy Transition | Tony Klein, Chair: House Energy and Natural Resources, Asa Hopkins, Director of Planning, Department of Public Service. Gabrielle Stebbins, Director, Renewable Energy Vermont |

| 10/5 | Student Alumni: Making a Difference in the World | Panel: Recent UVM grads in energy-related fields |

| 10/6* | The Climate Crisis and The Case for Hope | Al Gore, former Vice-President, United States |

| 10/12 | Carbon Taxes: Why We Need Them | Yoram Bauman, The world’s only “stand-up” Economist |

| 10/19 | Challenging the Car: Creating places where biking is safe & easy | Steve Clark, League of American Bicyclists, Community Organizer |

| 10/26 | Vermont’s Energy Company of the Future: A Customer Driven Energy Transformation | Mary Powell, President & CEO, Green Mountain Power |

| 11/2 | “The War on Coal:” Big Fossils’ Response to Divestment | Jen Schneider, Political Science Dept. Boise State University |

| 11/9 | The Transportation Transition: Complete Streets | Roger Millar, Director, SmartGrowth America |

| 11/16 | Energy Transitions in the Developing world: South Africa Settlements | Steve McCauley, Worcester Polytechnic Institute |

| 11/30 | Design Matters: Building Green | Rolf Keilman, Partner, Truex-Cullins, Vermont |

* Al Gore presentation is in the Ira Allen Chapel, special time, 10:15 a.m. Oct. 6

For more information contact

Fred Hall fhall@uvm.edu

Roison Low rlow@uvm.edu

Richard Watts rwatts@uvm.edu

Efficiency Vermont, Renewable Energy Resource Center, Renewable Energy Vermont and Clean Energy Development Fund combine efforts to bring up to $5,500 in rebates to Vermonters who heat local

Efficiency Vermont, Renewable Energy Resource Center, Renewable Energy Vermont and Clean Energy Development Fund combine efforts to bring up to $5,500 in rebates to Vermonters who heat local

Through a generous opportunity, Vermonters now have a short-time frame before the new year to capitalize on a fantastic incentive offering that helps them save money, while supporting Vermont jobs and sustainable forests, while making sure they stay warm this winter.

Vermonters can get up to $5,500 to help switch from fossil fuel to local wood heating. Cash incentives are available from the Clean Energy Development Fund and Efficiency Vermont. Renewable Energy Vermont and the Renewable Energy Resource Center have partnered to help promote the incentives.

“We’ve been very happy with our decision to switch to a wood pellet boiler. Not only do we save money every year on our fuel bill, but we also love the fact that we’re helping to keep forests intact and logging jobs going,” says Mark Bushnell of Middlesex.

Vermonters who make the switch to wood pellet fuel typically save $1,500 annually when compared to oil and propane fuel heating options. And for those who are used to whole-home heating through their traditional boiler, the wood pellet boiler keeps it simple and complete. Advanced wood pellet boilers are fully automatic, so there’s no work for the home or business owner.

“I heated my home for years with a standard wood stove, but I’m happier with my wood pellet boiler. The new boiler is much more efficient and better for the environment because it is cleaner burning. And it feels great to be off fossil fuels,” says Susan Clark of Middlesex.

Wood pellet boilers, though not well known in the United States, are the primary way of heating in some parts of the world, including Upper Austria where more than 40,000 homes and businesses heat with wood from their background in an easy, seamless way. In fact, the State of Vermont and Upper Austria are involved in a Sister Statehood Agreement to help learning across both sides of the Atlantic to increase the uptake of this sustainable, local heating option.

“For many years, Vermont has been a national leader in the use of modern wood heating systems in large buildings like schools, office buildings, and apartment buildings. With pellets now available in bulk using specialized delivery trucks that conveniently blow pellets into a fuel bin and heating systems that are fully-automated, many homeowners and small businesses are also making the switch from oil and propane,” said Adam Sherman of the Biomass Energy Resource Center.

For more information, please go to www.advancedwoodheat.com

Media Contacts:

Renewable Energy Vermont, Ansley Bloomer, ansley@revermont.org (802) 595-0723

Biomass Energy Resource Center, Alayna Howard, ahoward@veic.org (802) 540-7656

Renewable Energy Resource Center, Alayna Howard, ahoward@veic.org (802) 540-7656

Efficiency Vermont, Alayna Howard, ahoward@veic.org (802) 540-7656

Clean Energy Development Fund, Andrew Perchlik, andrew.perchlik@state.vt.us (802) 828-4017

The Vermont Bioenergy Initiative connects diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. Explore the initiative’s extensive and accessible set of bioenergy resources for replication in rural communities across the United States and beyond.

Video

A series of informative educational showcase a range of biofuel possibilities; from research and crop farming to feedstocks and fuel. The videos were developed by the Vermont Sustainable Jobs Fund, UVM Extension researchers, KSE Partners, and the Vermont Bioenergy Initiative grantees.

Calculators

Two calculators, developed by UVM Extension, help connect potential costs and profits associated with oilseed production:

- Grass Biomass Production and Harvest Cost Estimator

- Vermont Oilseed Crop Production Cost and Profit Calculator

Course Work

- Biomass to Biofuels, University of Vermont: This semester-long course covers liquid and solid biofuels, biogas and bio-electricity, and environmental, social and economic issue related to biofuels. The course includes guest lecturers and field days. Available for variable credits.

- Biomass to Biofuels, Vermont Technical College: The development of this course and associated materials led to an online repository of resources for the classroom covering biomass to biofuels.

- Digester Operations Master Certificate, Vermont Technical College: a twelve week program designed for participants to work directly with operations staff of Vermont Tech’s anaerobic digester and come away with understanding of the mechanics and operations of a digester system, as well as other areas such as permitting, regulatory compliance and record keeping.

- Alternative Fuel Vehicles: Biodiesel, part of the Green Trainings series at Vermont Technical College: This 2-day course covers engine systems, biodiesel blends and biodiesel production, including a demonstration of fuel-making equipment.

- Biofuels Course at Yestermorrow Design/Build School, part of the Green Trainings series at Vermont Technical College: This weekend workshop enables students to begin replacing fossil fuels with biofuels, such as adapting engines to run on straight vegetable oil. 1 credit.

Textbook

Bioenergy: Biomass to Biofuels; is an innovative new textbook that provides insight into the potential and current advances and benefits of biofuel. Contributions include an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Reports

A variety of reports are available which cover a range of topics including seed preparation and storage:

- Institute for Energy and the Environment at Vermont Law School.Legal & Regulatory Review of On-farm Biodiesel Production. 2015.

- Chris Callahan and Netaka White,Vermont On-Farm Oilseed Enterprises: Production Capacity and Break-even Economics. July 2013.

- Nell Campbell, Local Production for Local Use to Supply a Portion of Vermont’s Energy Needs.May 2009.

- Emily J. Stebbins. Technical and Economic Feasibility of Biodiesel Production in Vermont: Evidence From a Farm-Scale Study and a Commercial-Scale Simulation Analysis. May 2009.

- Christopher W. Callahan,A Feasibility Analysis of a Mobile Unit for Processing Oilseed Crops and Producing Biodiesel in Vermont. December 2008.

- Emily Stebbins, The Market Potential of Farm-Scale Oilseed Crop Products in Vermont. February 2008. (See also the Executive Summary)

- John Williamson & Tanner Williamson – State Line Biofuels, LLP, Chris Callahan – Callahan Engineering, PLLC, Feasibility Analysis:_Solar Seed Dryer and Storage Bin at State Line Farm, Bennington, VT. October 2008

- Christopher W. Callahan, A Feasibility Study of a Mobile Unit for Processing Oilseed Crops and Producing Biodiesel in Vermont. December 2008

- Kenneth Mulder, Ph.D., Galen Wilkerson, Emily J. Stebbins.Homegrown Fuel: Economic Feasibility of Commercial-Scale Biodiesel Production in Vermont. September 2007.

- The Vermont Biodiesel Project: Building Demand in the Biofuels Sector – Final Report. October 2006. (See also theExecutive Summary)

- Vermont Department of Buildings and General Services, Vermont Biodiesel Pilot Project: Emissions Testing of Biodiesel Blends With #6 Fuel Oil At the Waterbury State Office Complex – Final Report. September 2006.

- Laboratory and Field Testing of Biodiesel in Residential Space Heating Equipment – Final Report. August 2006.

- Vermont Biodiesel Supply Chain Survey – Final Report. April 2006.

- Wilson Engineering,Grass Energy in Vermont and the Northeast, May 2014.

Technical Advice

Connect directly with the Vermont Bioenergy Initiative’s technical assistance providers:

Oilseeds for Biofuel

- Heather Darby, Agronomic and Soils Specialist

- University of Vermont Extension, Northwest Crops and Soils Team

- (802) 524-6501

- darby@uvm.edu

- Chris Callahan, PE, Agricultural Engineer

- University of Vermont Extension

- (802) 773-3349

- callahan@uvm.edu

Grass for Heating Fuel

- Sidney Bosworth, Extension Professor

- University of Vermont College of Agriculture and Life Sciences

- (802) 656-0478

- bosworth@uvm.edu

Algae for Biodiesel

- Anju Dahiya, Instructor and Principal

- University of Vermont and GSR Solutions

- (802) 310-1936

- adahiya@uvm.edu

In early 2014 Full Sun Company, a small start-up business was co-founded by Netaka White and Davis McManus. Fueled by an interest to help family farms grow, Full Sun began processing sunflower and non-GMO canola oil crops into specialty food-grade oil and high-protein meal for the farmers. Sunflower and canola oil distribution picked up quickly through local CSAs, farm stores, specialty food shops, health and wellness centers, and direct sales to chefs in the Northeast.

Netaka White previously served as the Vermont Bioenergy Initiative’s (VBI) program director, which directly helped to develop the business model to nurture farm partnerships, both as growers and recipients of oilseed meal – the other product that’s generated from making the oil. At Full Sun oilseeds are pressed with large mechanical machinery, producing oil and a granular meal. The team at Full Sun Company learned a lot about seed storage and oil pressing from the early VBI grantees, such as John Williamson of State Line Farm, and Roger Rainville of Borderview Farm.

The first of the two products, the seed meal, has been used as fuel for pellet stoves, or as is the case with Full Sun, sold as fertilizer for crops, or nutritional meal for livestock. At full operation, Full Sun can pump out one ton of meal per day – necessary to meet the growing demand of such customers as The Intervale in Burlington, Vermont and several local pig, poultry, dairy, and beef producers.

Full Sun Company employee, Zach Hartlyn, moves an off-spec oil barrel for biodiesel production

Credit: Full Sun Company

The second product, the oil, is used as culinary oil for cooking. Staying true to their commitment to an extraordinary culinary product, Full Sun Company diverts any of the oil that does not meet their standards to Vermont Bioenergy Initiative biofuel producers to undergo further processing and become biofuel. Approximately 250-300 gallons of off-spec oil for biodiesel has been processed since February, 2014.

In October, 2014, Full Sun Company halted operation to make room for growth to meet the increased demand for their products and scale up to align with Vermont’s accelerating agricultural economy. White and McManus acquired the former Vermont Soap building in Middlebury, Vermont in order to build a full scale mill and achieve their anticipated greater capacity. Over the course of one of the coldest winters in recent history, the Full Sun team made the renovations and adjustments needed to repurpose the building into the first non-GMO verified oil mill in New England. By March of 2015 Full Sun Company had pressed sunflower and canola seeds to make their first batch of specialty oils. The new operation can yield 130 gallons of oil per day – about 2600 gallons per month!

With no shortage of innovation or ambition, White notes, “David and I are in this with the interest of having a transformative effect on local agriculture and food systems.” Well on their way, the operation is certified GMO free, and the next steps are being taken towards becoming certified organic.

As they grow, Full Sun would like to buy from local grower-suppliers and work with local businesses to package and label feed to be distributed to farmers of varying sizes, from backyard chicken growers to larger operations. Collaborating with Vermont breweries and distilleries is also in queue. Full Sun is working with one local distillery to put together “a package” for farmers so they have markets for profitable grain crops throughout four years of rotation (rye, wheat, sunflowers, etc.) and can offer farmers the indexed prices for these locally grown grains and oilseeds.

29 Jun 2015

Soybeans for On-farm Biodiesel Production

Mark Mordasky, owner of Rainbow Valley Farm in Orwell, Vermont has been growing soybeans as a cash crop and for on-farm biodiesel and animal feed since 2008. When fuel prices began to climb, Mark took initiative and started searching for an innovative and more cost efficient way to meet his farm’s energy demands. The Vermont Sustainable Jobs Fund was able to help Mark take his first steps towards sustainable biofuel production. Mark is able to press these soybeans after harvesting and make two distinct products, oil and meal. The meal is an instantly marketable product and can be sold as feedstock or organic fertilizer; the oil will be further processed into biodiesel.

Soybeans crops are well suited for biodiesel production in Vermont and perform best in heavy soil like those found in Addison County, as University of Vermont Extension Agronomist, Heather Darby explains. Soybeans don’t always do well in in light, well drained soils, and as with any crop the best way to understand the demands of any crops is to contact your University Extension and have your soil tested. Additionally, because soybeans are a legume, they produce nitrogen in association with bacteria, meaning that these crops don’t require the application of additional nitrogen to produce a high yield. These low input, high yield crops are fairly easy to grow, are well suited to the Vermont climate, and afford farmers flexible planting dates. Heather and the rest of the UVM Extension team have seen yields ranging from 35 bushels per acre to up to 85 bushels per acre with varying practices.

In the below video, Mike Mordasky shares his experience and knowledge of soybean production from planting through harvesting harvest and beyond to storage and the creation of the final products. In addition, Heather Darby shares here insights into maturity groupings, variety selection, and best growing practices.

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.