02 Nov 2015

Vermont Bioenergy Initiative proves biofuel potential for state and concludes ten year project

By: Ellen Kahler

VT Bioenergy Team – L to R (Chris Callahan – UVM Extension, Kirk Shields — Green Mountain Power, Christy Sterner – US DOE, Larry Scott – Ekolott Farm, Ellen Kahler – VSJF, John Williamson – Stateline Biofuels) at Green Mountain Power’s Energy Innovation Center in Rutland

Vermont can produce more of its own biofuel energy and the environmental and potential economic benefits of local bioenergy have been proven by the Vermont Bioenergy Initiative – a program of the Vermont Sustainable Jobs Fund. Since 2005, the Vermont Bioenergy Initiative has invested more than $2.5 million in innovative bioenergy research, projects, and people so Vermont can locally produce more of the state’s energy needs – from a variety of agricultural and algal feedstocks.

US Senator Patrick Leahy made the investment at this scale possible through Congressionally Directed Awards from the US Department of Energy (US DOE). The funding concludes in early 2016, at which point a complete impact report will be released by the Vermont Sustainable Jobs Fund, who has served as the intermediary between the US DOE and 52 individual Vermont bioenergy projects over the past ten years.

Research, development, and early stage demonstration projects have included:

- Investing in 2 on-farm methane digesters;

- Building farm-scale infrastructure to turn oilseed crops such as sunflowers into biodiesel to run farm tractors;

- Growing switchgrass and densifying it into “pucks” that are burned in a high efficiency commercial boiler instead of propane;

- Identifying the most lipid producing strains of native Vermont algae which can feed off the excess nutrients from methane digesters and can eventually be harvested to make biodiesel or jet fuel;

- Developing two “Biomass to Biofuels” college level courses which run repeatedly at UVM and VT Tech to inspire and train the next generation of bioenergy experts and technicians;

- Exploring the logistics of bulk wood pellet delivery systems to Vermonters’ homes;

- Organizing a number of learning opportunities and conferences for oilseed, grass and algae researchers, farmers and entrepreneurs to attend;

- Providing agronomic and engineering support to oilseed and grass farmers;

- Educating the general public about why the local production for local use of energy crops from Vermont farms and forests makes good economic and ecological sense.

VT Bioenergy Team 2 – L to R (Roger Rainville – Borderview Farm, Christy Sterner – US DOE, Heather Darby – UVM Extension, Natasha Rainville – Borderview Farm) at Borderview Farm, Alburgh VT

The Vermont Bioenergy Initiative is a unique effort and one that is gaining resonance in other parts of rural America. The initiative’s resource website, www.VermontBioenergy.com is utilized by biofuel producers, educators, and technical service providers from across the country.

The work conducted over the past ten years by the Vermont Bioenergy Initiative to conduct research, provide technical assistance, and develop infrastructure in emerging areas of bioenergy will continue with the initiative’s partners at UVM Extension and the Vermont Agency of Agriculture, Food & Markets. As Vermont moves forward – being innovative and increasingly focused on generating renewable energy from the land and forests – the research and infrastructure the Vermont Bioenergy Initiative has invested in over the past ten years will endure and spawn the next wave of bioenergy development in the state.

Ellen Kahler is executive director of the Vermont Sustainable Jobs Fund (VSJF), a non-profit organization created by the State of Vermont to help develop Vermont’s sustainable agriculture, renewable energy, and forest product businesses. Since 2005, the Vermont Bioenergy Initiative has been a VSJF program that connects diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. Learn more at www.VermontBioenergy.com.

Algae for biofuel has been a long time component of the local biofuel production for local use model pioneered by the Vermont Bioenergy Initiative. At the forefront of these efforts has been Anju Dahyia, a VBI grantee, lead biofuels instructor at the University of Vermont, and president of General Systems Research (GSR) Solutions. When the Vermont Fuel Dealers Association received a USDA Rural Business Enterprise Grant to utilize waste materials from Vermont farms to produce sustainable distillate fuel, Anju and GRS Solutions were already in a prime positon to conduct the necessary research.

Algae for biofuel has been a long time component of the local biofuel production for local use model pioneered by the Vermont Bioenergy Initiative. At the forefront of these efforts has been Anju Dahyia, a VBI grantee, lead biofuels instructor at the University of Vermont, and president of General Systems Research (GSR) Solutions. When the Vermont Fuel Dealers Association received a USDA Rural Business Enterprise Grant to utilize waste materials from Vermont farms to produce sustainable distillate fuel, Anju and GRS Solutions were already in a prime positon to conduct the necessary research.

GSR is developing a method of producing algae biofuel to replace traditional fossil fuels in motor vehicles, heavy farm equipment, and even airplanes at Charlotte’s Nordic Dairy Farm as a second tier to the already operational anaerobic digesters contributing to Vermont’s distributed energy generation grid. The process to produce algal biofuel has the potential to prevent nutrients such as phosphorus and nitrogen from making their way into local lakes and waterways. Nordic Dairy Farm’s owner, Clark Hinsdale, explained at a recent press event on his farm: “the best way to capture excess nutrients on farms is to never let them get beyond the boundaries of the farmstead.”

The current anaerobic digestion system “Cow Power,” utilized by Green Mountain Power, functions by using the methane byproduct harvested from constantly produced cow manure to make electricity that then is sold to Green Mountain Power customers. The research done by GSR focuses on another byproduct of digestion – the nutrient dense liquid waste, previously left unused for power purposes.

The oleaginous algae strains that Anju Dahyia has been working with since 2008 thrive on this dense waste and after the algae has consumed the available nutrients, the creation of the distillate fuel can begin. The result makes the process a closed loop system, and means that dairy farmers like Nordic Dairy (whose cows produce up to a ton of manure a day) would be able to sell algae derived biofuel to local fuel dealers and create granular organic fertilizer. According to Dahyia, Hinsdale’s 300 cows alone have the potential to produce anywhere between 20,000 to 30,000 gallons of biofuel each year.

The cost of production is estimated at $20 dollars per gallon, but Dahyia thinks that with increased scale will come a decreased price. At the recent press conference at the Nordic Dairy Farm site early in September, Mary Powell of Green Mountain Power outlined how the company is working with GSR Solutions to help increase scale and add more small refineries that mimic this operation. She went on to note the resiliency a community-sized digester refinery can add to a microgrid.

Speaking to ABC local 22 News, Matt Cota, Director of the Vermont Fuel Dealers Association added, “We know that bio-heat, renewable blended fuel, combined with heating oil works in customers tanks and burners, so if we can source that locally, it would be a great thing for Vermont’s economy, for Vermont famers, Vermont fuel dealers and consumers all across Vermont.”

Richard Altman of the non-profit Commercial Aviation Fuels Initiative was also in attendance and trumpeted that “community-scale digester-refineries in the region might be feasible by 2020,” noting that this project is just a start.

Also on the horizon, GRS Solutions is already working to go further with this technology by incorporating food waste into this digester system. While this system may be in its early stages, one thing is for sure, Vermont energy stakeholders are lining up to show their support and contribute to this more than viable option for local energy production.

For more watch the local WCAX coverage of the September 3rd press conference and to learn more about Algae Bioenergy in Vermont see our other post Algae Biofuel – Vermont’s Search for Viable and Cost-Effective Methods

19 Oct 2015

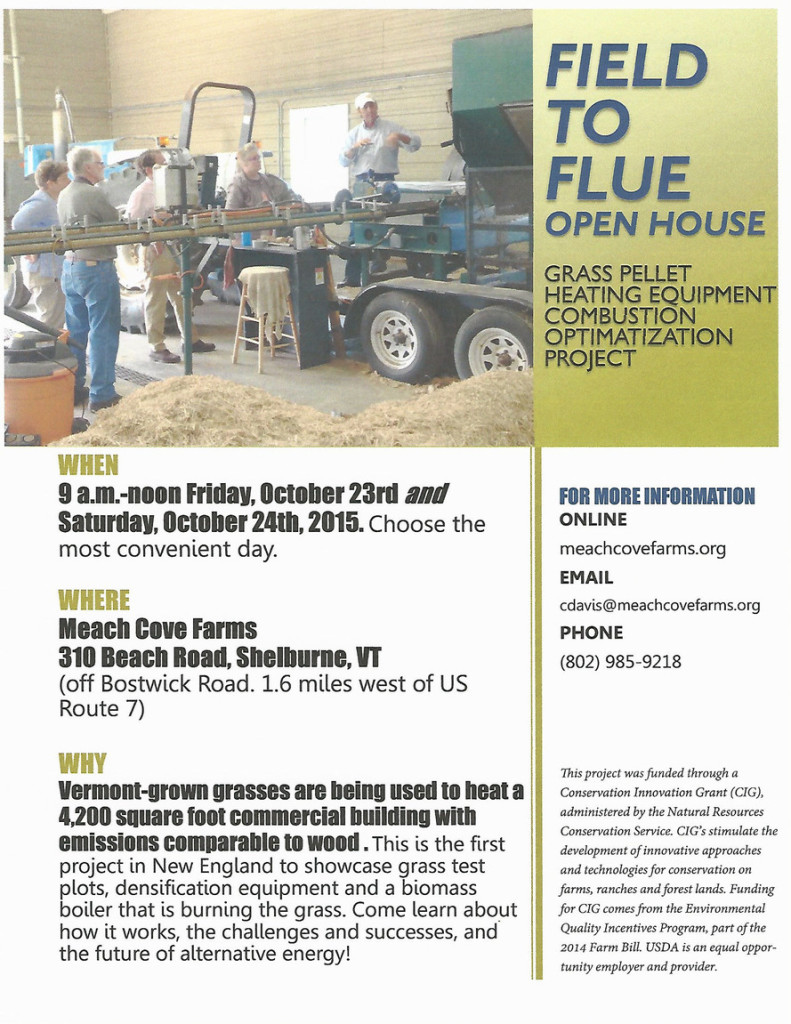

Field to Flue Open House at Meach Cove Farms

Vermont-grown grasses are being used to heat the Biomass Building – a 4,200 square foot commercial building at Meach Cove Farms in Shelburne. Local residents, community leaders, and renewable energy enthusiasts are invited to visit Meach Cove Farms Friday, October 23 – Saturday, October 24 for an Open House to learn how grass pellets are generating heat in a biomass boiler – an emerging source of bioenergy in Vermont.

Meach Cove Farms is a 1,000-acre certified organic farm primarily growing soy beans, wheat, rye, and corn as well as wine grapes, woodlands, and switchgrass trial plots for use in grass energy production. The Open House will offer a complete demonstration of the Grass Pellet Heating Equipment Combustion Optimization project – the first project in New England to showcase grass test plots, densification equipment, and an EvoWorld biomass boiler that burns the grass.

Meach Cove Farms began collaborating with Dr. Sidney Bosworth of the University of Vermont College of Agriculture and Life Sciences and the Vermont Bioenergy Initiative in 2009 to assess the potential of different species of grass as solid biofuel for heating applications.

In September 2011 Meach Cove Farms was awarded an USDA Natural Resources Conservation Service Conservation Innovation Grant to research the feasibility of Vermont grown grass pellets and heating equipment potential as an emerging renewable energy source in Vermont. The biomass boiler being featured at the Open House was funded through a Conservation Innovation Grant (CIG) administered by the Natural Resources Conservation Services.

IF YOU GO:

Meach Cove Farms is located at 310 Beach Road in Shelburne (off Bostwick Road, 1.6 miles west of Rte 7). The Open House runs from 9 am – 12 noon both Friday and Saturday, October 23-24. There is no cost and both days are open to the public. More info at www.meachcovefarms.org, 802-985-9218.

10 Aug 2015

Bioenergy Events 2015

The team  at Vermont Bioenergy Initiative has worked to put together a comprehensive list of bioenergy events for you! This list will be updated as more events arise. If you know a bioenergy events that you think should be on the list, tweet it to us! @VTbioenergy

at Vermont Bioenergy Initiative has worked to put together a comprehensive list of bioenergy events for you! This list will be updated as more events arise. If you know a bioenergy events that you think should be on the list, tweet it to us! @VTbioenergy

- September

- Modern Wood Pellet Heating Forum, Tuesday, Sep. 15, 2015, 6 – 8:30pm, Montshire Museum in Norwich, Vermont

- Ag Innovation Showcase September 14-16, 2015 St. Louis, MO

- 2nd International Conference on Past and Present Research Systems of Green Chemistry. September 14-16, 2015. Orlando, Florida

- Switchgrass III. September 30 to October 2, 2015. Knoxville, TN

- Algae Biomass Summit September 30-October 2, 2015 Washington, DC

- October

- Renewable Energy 2015 Conference & Expo. October 8-9 2015. Burlington, VT

- National Advanced Biofuels Conference & Expo. October 26 – 28, 2015. Omaha, Nebraska

- 2015 TAPPI PEERS Conference – Sustainable Solutions for Our Future. October 25-28, 2015 in Atlanta, Georgia.

- International Bioenergy and Bioproducts Conference 2015 – 10/28 – 10/30 Atlanta, United States

- 3rdAnnual National Bioenergy Day

- November

- April

27 Jul 2015

Summit on Creating Prosperity and Opportunity Confronting Climate Change – Looking Back and Looking Forward

The Summit on Creating Prosperity and Opportunity Confronting Climate Change brought together over 400 innovative business, non‐profit, and community leaders, elected officials, public policy advocates, students, and interested residents to begin to frame policy and investment strategies to advance the development of the Vermont Climate Economy. Summit participants developed a list of key practical actions to serve as a launching point for the Vermont Climate Change Economy Council (VCCEC), a group charged with a one year mission to develop a structured plan with practical actions to reduce carbon emissions and stimulate green economic development in Vermont. The Council will build a set of public/private strategies designed to promote economic opportunity, innovative business development, investment, and job creation in Vermont.

The Summit on Creating Prosperity and Opportunity Confronting Climate Change brought together over 400 innovative business, non‐profit, and community leaders, elected officials, public policy advocates, students, and interested residents to begin to frame policy and investment strategies to advance the development of the Vermont Climate Economy. Summit participants developed a list of key practical actions to serve as a launching point for the Vermont Climate Change Economy Council (VCCEC), a group charged with a one year mission to develop a structured plan with practical actions to reduce carbon emissions and stimulate green economic development in Vermont. The Council will build a set of public/private strategies designed to promote economic opportunity, innovative business development, investment, and job creation in Vermont.

Over the course of 2015, VCCEC will evaluate findings, key ideas and suggested action steps derived from the Summit, lead regional public forums, evaluate and summarize research findings, interview key stakeholder groups, and consider model economic development strategies from other state and countries. During 2015, the group will develop a strategic platform of recommendations for action, and report to the Vermont legislature, the Governor of Vermont and the public in January 2016. The Vermont Council on Rural Development (VCRD) will provide support to their work and then help promote the platform of action that comes from its deliberants. Goals of the Vermont Climate Change Economy Council are to:

- Identify opportunities created by climate change to strengthen Vermont’s economy through strategies advancing key business clusters and economic sectors.

- Build an increased sense of unity in Vermont around policies to confront and mitigate the impact of climate change and to advance economic opportunities and solutions that respond to climate change.

- Build a public information campaign to celebrate innovation and Vermont’s green business leadership; internally and externally marketing to build the Vermont brand as an economic/environmental problem solver.

- Expand Vermont’s economic brand around climate change solutions to retain and attract youth and creative entrepreneurs to locate throughout the state.

Vermont businesses and nonprofits are addressing climate change – both its challenges and opportunities. Their creative solutions are a growing part of our state’s economy. What are your experiences? Do you have ideas about how Vermont can grow jobs and nurture innovative business development in sectors ranging from clean energy, to recycling, transportation systems, and thermal efficiency?

Jo![Regional_Forum_Flyer5_15_statewide[1]](https://vermontbioenergy.com/wp-content/uploads/2015/07/Regional_Forum_Flyer5_15_statewide1-150x150.jpg) in the Vermont Council on Rural Development and local business leaders at a forum on “What’s Next for Vermont’s Climate Change Economy?” Forums will take place at 7:00pm at the Paramount in Rutland (Aug 26), the Latchis Hotel in Brattleboro (Oct 6), and City Hall in Burlington (Oct 29). Come to the forum(s) most convenient for you.

in the Vermont Council on Rural Development and local business leaders at a forum on “What’s Next for Vermont’s Climate Change Economy?” Forums will take place at 7:00pm at the Paramount in Rutland (Aug 26), the Latchis Hotel in Brattleboro (Oct 6), and City Hall in Burlington (Oct 29). Come to the forum(s) most convenient for you.

These forums are the next step for public input to the Vermont Climate Change Economy Council, a group working to develop a practical plan to reduce carbon emissions and stimulate economic development in Vermont. To learn more about the forums and the Council visit VCRD’s website at vtrural.org, download the event flyer (pdf).

For more information about the results of the summit, Click HERE to read the report and follow the hashtag #VTClimateEconomy and Vermont Council on Rural Development on Twitter at @VTRuralDev for more updates!

13 Jul 2015

Making Biofuel

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

Algae produces more than half of the oxygen on the planet, while consuming vast amounts of heat-trapping carbon dioxide and taking up nutrients like nitrogen and phosphorous to make biomass and energy. The lipids, or oil, that algae produce can be extracted and processed into renewable fuels such as biodiesel. Algae are an excellent source of oil for making biodiesel, which could displace substantial volumes of petro-diesel for heating and transportation. Microalgae reproduce rapidly, and they grow on non-agricultural land, so they do not compete with food, feed, or fiber production.

The keys to commercializing algae for biofuel production include identifying and cultivating native species, optimizing growing conditions in natural and artificial environments and the efficient harvest and oil extraction of algal biomass. At the forefront of this algae biofuel research is Dr. Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. Dr. Dahiya has been searching for high lipid algae strains, and scaling those up to a level that could be available for commercial use, especially for biofuels.

“At GSR Solutions, we are looking at producing algae not just for biofuels, but combining it with waste water treatment and to produce other valued byproducts as well. This is very significant, because this would make algae production cost-effective. This would also help in nutrient recovery,” says Dahiya.

innovative new textbook that provides insight into the potential and current advances and benefits of biofuel

Some of the findings and knowledge afforded by Dr. Dahiya’s research are available in the new introductory textbook, Bioenergy: Biomass to Biofuels, which was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories. Dr. Dahiya will also be using this textbook as the basis for a University of Vermont Bioenergy Course offered for the 2015 fall semester.

In the below video, Vermont researchers and entrepreneurs demonstrate their innovations in algae to biofuel research and development.

For more algae bioenergy resources see the visit the Algae section of the Vermont Bioenergy Website.

Learn more about the mentioned UVM Bioenergy Course visit the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

For more information on the introductory textbook Bioenery; Biomass to Biofuels see our write up on the book here!

In order to meet the goals set by Vermont’s comprehensive energy plan for Vermont to produce 90 percent of the state’s energy needs from renewables by 2050 and reduce Vermont’s greenhouse gas emissions by 50 percent from a 1990 baseline, Vermont farmers will have an important role to play. As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more important prompting statewide energy and agriculture collaborations. In the following episodes of Across the Fence, UVM Extension agricultural engineer and Vermont Bioenergy Initiative biofuels consultant, Chris Callahan, shares two stories about Vermont farmers who are rethinking their on-farm energy. In both examples UVM extension is able to work with the farmers to help make cleaner, renewable on-farm energy sources a practical solution that saves money and results in greenhouse gas reductions.

Learn more in a series of on-farm energy case studies produced by Vermont’s Farm to Plate Initiative.

19 May 2015

Mitigating Potential Biomass Feedstock Pests

The Vermont Bioenergy Initiative aims to connect diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution. As we move into the growing season, there are a variety of pests that can potentially affect sunflower, canola, and soybean biomass feedstock production. In this video a University of Vermont agronomist explains how to control theses potential biomass feedstock pests and increase crop, and eventually biofuel, yields without heavy reliance on pesticides and herbicides.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.