29 Jun 2015

Soybeans for On-farm Biodiesel Production

Mark Mordasky, owner of Rainbow Valley Farm in Orwell, Vermont has been growing soybeans as a cash crop and for on-farm biodiesel and animal feed since 2008. When fuel prices began to climb, Mark took initiative and started searching for an innovative and more cost efficient way to meet his farm’s energy demands. The Vermont Sustainable Jobs Fund was able to help Mark take his first steps towards sustainable biofuel production. Mark is able to press these soybeans after harvesting and make two distinct products, oil and meal. The meal is an instantly marketable product and can be sold as feedstock or organic fertilizer; the oil will be further processed into biodiesel.

Soybeans crops are well suited for biodiesel production in Vermont and perform best in heavy soil like those found in Addison County, as University of Vermont Extension Agronomist, Heather Darby explains. Soybeans don’t always do well in in light, well drained soils, and as with any crop the best way to understand the demands of any crops is to contact your University Extension and have your soil tested. Additionally, because soybeans are a legume, they produce nitrogen in association with bacteria, meaning that these crops don’t require the application of additional nitrogen to produce a high yield. These low input, high yield crops are fairly easy to grow, are well suited to the Vermont climate, and afford farmers flexible planting dates. Heather and the rest of the UVM Extension team have seen yields ranging from 35 bushels per acre to up to 85 bushels per acre with varying practices.

In the below video, Mike Mordasky shares his experience and knowledge of soybean production from planting through harvesting harvest and beyond to storage and the creation of the final products. In addition, Heather Darby shares here insights into maturity groupings, variety selection, and best growing practices.

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

01 Jun 2015

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”

In order to meet the goals set by Vermont’s comprehensive energy plan for Vermont to produce 90 percent of the state’s energy needs from renewables by 2050 and reduce Vermont’s greenhouse gas emissions by 50 percent from a 1990 baseline, Vermont farmers will have an important role to play. As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more important prompting statewide energy and agriculture collaborations. In the following episodes of Across the Fence, UVM Extension agricultural engineer and Vermont Bioenergy Initiative biofuels consultant, Chris Callahan, shares two stories about Vermont farmers who are rethinking their on-farm energy. In both examples UVM extension is able to work with the farmers to help make cleaner, renewable on-farm energy sources a practical solution that saves money and results in greenhouse gas reductions.

Learn more in a series of on-farm energy case studies produced by Vermont’s Farm to Plate Initiative.

19 May 2015

Mitigating Potential Biomass Feedstock Pests

The Vermont Bioenergy Initiative aims to connect diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution. As we move into the growing season, there are a variety of pests that can potentially affect sunflower, canola, and soybean biomass feedstock production. In this video a University of Vermont agronomist explains how to control theses potential biomass feedstock pests and increase crop, and eventually biofuel, yields without heavy reliance on pesticides and herbicides.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Coming this fall the University of Vermont will be offering a bioenergy course taught by Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. This course is open to both degree and non-degree students from any background or department, as well as farmers, entrepreneurs, and teachers interested in developing curriculum, or projects at school or college levels. This course is also approved for graduate credit.

Potential participants are offered the option of variable credits, ranging from 0 to 6 credit hours. This allows prospective students to only attend lectures and have access to online course materials for 2 credits; further their experience with the addition of hands-on labs and field trips for 3 credits; or participate in all aspects of the class while additionally applying lessons to a service learning project with a community partner, earning 4 credits. Participants have the ability to add up to 2 more credits, totaling no more than 6, for additional work with the community partner pending special permission from the course instructor.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Lectures will be held twice a week between September 18th and December 9th of 2015. Friday lectures will be on campus from 4:05 pm to 7:05 pm, followed by Saturday morning field trips between 10:00 am and 1:00 pm for those students who elected for 3 credits or more. The course required textbook, Bioenergy: Biomass to Biofuels, was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories.

Learn more about this course at the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

Nick Meyer of North Hardwick Dairy, an Organic Valley milk producer, was able to reduce energy costs and increase self-sufficiency by growing sunflowers for biodiesel and meal while maintaining a wind turbine to help cover electricity needs.

We all know food gives us energy. But we might sometimes lose sight of the amount of energy involved in producing, processing and delivering that food to our plates. Everything requires energy: from tractors plowing and planting to producing fertilizer or compost; from milking cows and keeping that milk cold to storing and transporting vegetables. This energy costs farms real money and it is sometimes a major category of expense. Energy costs are typically one of the highest for farms, rivaling feed costs on dairy farms and labor costs on vegetable farms.

As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more and more important. This has been part of Vermont’s Farm to Plate Strategic Plan and the associated network of people working on implementing that plan. The plan includes goals related to energy, including; reducing farm production expenses, reducing adverse environmental impacts from farm and food system activities, reducing energy use, and increasing renewable energy use in the food system.

One example of how this is actually working is a group called the Farm to Plate Energy Cross Cutting Team: a group of energy specialists from Efficiency Vermont, the Agency of Agriculture, UVM’s Rubenstein School and UVM Extension, The Vermont Bioenergy Initiative, USDA NRCS and private companies. The team meets regularly to learn from each other and take on specific projects such as the recent set of seven “Energy Success Stories” which were released at the 2014 Farm Show, showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production.

Chaired by Efficiency Vermont planning manager, JJ Vandette, the energy team will continue to address the Farm to Plate Efficiency and Renewable Energy Goal to decrease overall food system energy consumption and increase food system renewable energy production and the Farm to Plate Environmental Impacts Goal to decrease adverse environmental impacts from farming and food system activities—while helping to decrease production expenses—also a goal of the Farm to Plate Strategic Plan.

The team is always interested in having new members. If you have an interest in energy, especially energy on farms and in the food system, we’d love to hear from you. JJ Vandette can be reached at jvandette@veic.org or 802.540.7915.

Data sources and analysis at www.vtfarmtoplate.com/getting-to-2020.

2014 was a busy year for the Vermont Bioenergy Initiative as we engaged in national outreach efforts to share our work connecting diversified agriculture and local renewable energy production for on-farm and community use in ways that be applicable to rural areas around the country. These rural areas are often at “the end of the pipeline” and are subject to higher and more volatile costs for energy. The Vermont Bioenergy Initiative “local production for local use” model shows that rural communities can produce some of their own energy, thereby improving their energy security and benefitting from more predictable and affordable energy prices. Any farm in any part of the country can grow and process their own fuel, using the best practices developed by the collaborating farms and UVM Extension researchers working in partnership with the Vermont Bioenergy Initiative. Funding for our program work to support research, technical assistance, and infrastructure development in emerging areas of bioenergy was secured by US Senator Patrick Leahy and the US Department of Energy.

Recent news we distributed to local, regional, and national audiences includes:

Local production for local use is biofuel model that works in Vermont.

Vermont sunflowers to help provide biodiesel power.

We have worked with several regional and national publications to secure editorial specifically featuring oil crops for on-farm biodiesel and feed, and grass energy for heating.

Check out the recent interview with our UVM Extension consultant and agricultural engineer, Chris Callahan in Biofuels Journal.

Read about alternative energy innovations on the farm featuring farms a part of the Farm Fresh Fuel Project in Farming Magazine.

The Grass Energy Report we released summer 2014 was featured extensively in both Renewable Energy World and On Pasture Magazine.

Visit the Green Energy Times website for our ongoing column, Emerging Frontiers in Bioenergy and follow the Vermont Bionenergy on Twitter for current news, trends, and tweets on renewable energy in Vermont and beyond.

16 Feb 2015

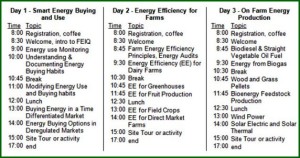

Upcoming Farm Energy IQ Training

It’s not too late to register for the upcoming Farm Energy IQ Training for New England Agricultural Service Providers. This training will take place starting Monday, February 23rd at 8:00 a.m. and will end Wednesday February 25 in Fairlee, Vermont. Organized by individuals from the University of Vermont Extension Service, Penn State, and Rutgers University, this three day training is a great opportunity for those interested in on farm energy to learn and apply their skills as well as network with other attendees. The Farm IQ Energy Training is funded generously by Northeast Sustainable Agriculture Research and Education (SARE) Program as part of a regional professional development program to bring the latest developments in the field to individuals who can best apply them.

This conference will provide a range of opportunities to learn or improve energy purchasing, calculating, conservation, production, and analysis.Attendees will even have the opportunity to apply skills via hands-on activities and by visiting local operations. Over the three days these lessons will be compared for application on farms in different settings. In addition, attendees will receive a comprehensive binder with all the material covered in the workshops as well as supplemental materials to refresh and share material as well as continue learning.

This conference is a great opportunity to solidify one’s knowledge by learning from on hand specialist and being immersed with in the material. If you happen to miss this particular training, the same workshop will be offered in Pennsylvania, March 10th to the 12th and again in New Jersey from April 8th to the 10th.

Read more about renewable energy events around the country on the Vermont Bioenergy Field Notes blog

- February

- Biomass Boot Camp, February 23, Catonsville, MD

- Farm Energy IQ – Training for NE Ag Service Providers in VT February 23- 25, Fairlee, VT

- ACI’s 4th Carbon Dioxide Utilization Conference 2015 February 25-26 San Antonio, TX

- 2015 Executive Leadership Conference. 25 February – 1 March 2015. Phoenix, Arizona

- March

- World Agri-Tech Investment Summit. March 3-4, 2015 San Francisco, CA

- Waste to Biogas and Clean Fuels Finance and Investment Summit. March 3-4 San Jose, CA

- Farm Energy IQ – Training for NE Ag Service Providers March 10-12, 2015 State College, PA

- Advanced Bioeconomy Leadership Conference March 11-15, 2015 Washington, DC

- Next-Generation Defense Energy Symposium. 17 – 18 March, 2015. Washington, United States

- WEBINAR: Using B100 in Our Class-8 Trucking Operations (60 trucks) in Tennessee March 19, 2015 10:00 AM ET

- ACI’s Annual Lignofuels Americas Summit March 25-26, 2015 Milwaukee, WI

- Forest Products and Timberland Investment Conference. March 31-April 1, 2015. New York, NY

- April

- Applying Renewable Energy – Online Training April 01, 2015 at 09:00 AM to June 30, 2015 at 06:00 PM

- Farm Energy IQ – Training for NE Ag Service Providers in NJ, April 8- 10, Bordentown, NJ

- 5th Defense Renewable Energy Summit. 7-8 April 2015. Arlington, VA

- Good Jobs, Green Jobs 2015 April 13 Washington, D.C

- 2015 Northeast Biomass Heating Expo. April 16-18, 2015. Portland, ME

- Introduction to Renewable Energy Technologies Start date: 20 to 22, 2015

- International Biomass Conference and Expo. 20 -22 April 2015. Minneapolis, MN

- 37th Symposium on Biotechnology for Fuels and Chemicals. April 27 – 30, 2015 San Diego, CA