08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

01 Jun 2015

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”

19 May 2015

Mitigating Potential Biomass Feedstock Pests

The Vermont Bioenergy Initiative aims to connect diversified agriculture and local renewable energy production for on-farm and community use by supporting research, technical assistance, and infrastructure development in emerging areas of bioenergy including biodiesel production and distribution. As we move into the growing season, there are a variety of pests that can potentially affect sunflower, canola, and soybean biomass feedstock production. In this video a University of Vermont agronomist explains how to control theses potential biomass feedstock pests and increase crop, and eventually biofuel, yields without heavy reliance on pesticides and herbicides.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The Biomass Energy Resource Center (BERC), a program of the Vermont Energy Investment Corporation (VEIC), has launched a re-tooled web-based database for tracking the advancement of modern wood heating throughout North America. The newly revised searchable database houses key information on existing community-scale modern wood heating and combined heat and power systems across the U.S. and Canada, as well as an archive of links to case studies. Examples of community-scale facilities include schools, campuses, hospitals, prisons, multi-family or senior housing, government buildings, commercial buildings, and farms and greenhouses.

The database was originally created with funding from the U.S. Endowment for Forestry and Communities and further improvements were made with funding from the U.S. Department of Energy through the support of Vermont Senator Patrick Leahy. The re-tooled database is a user-friendly, interactive tool that will help collect and track information on a continuing basis. “This resource will provide stakeholders from a variety of backgrounds with a better understanding of the current demand for wood fuels as an energy source and the success of modern wood heating projects throughout North America,” said Adam Sherman, Manager of BERC at VEIC.

The database already contains more than 500 entries, but to ensure that this publicly available resource is accurate and up to date, BERC is asking for user participation. “We are committed to maintaining and building this database over time to ensure it remains a useful and reliable too, but this is a rapidly growing sector, so we need users to help,” said Sherman. “We need people to engage with the database; add new entries for facilities that have been missed and as new facilities come online, and edit existing entries that are incomplete.” With regular contributions, the database will continue to improve and grow.

With tens of thousands of annual visits and top Google search ranking, the BERC website is a high-visibility home for this important tool. The BERC database is designed to provide vital information on a specific subset of biomass energy facilities; community-scale biomass heating projects. The BERC database complements the Wood2Energy.org database that covers a broader spectrum of biomass energy facilities including power plants, sawmills, and pellet mills. Not only will the BERC database provide wood heating systems vendors the exposure and recognition for their projects, it also helps demonstrate that modern wood heating is becoming mainstream throughout North America. To learn more about using and contributing to the database visit www.biomasscenter.org/database.

About BERC

The Biomass Energy Resource Center (BERC) is a program of Vermont Energy Investment Corporation (VEIC). BERC works to advance the use of community-scale biomass energy throughout North America and beyond by providing technical consulting services, biomass energy program design and delivery, and education and outreach on benefits and best practices. BERC works with communities, federal, state and local governments, colleges and universities, businesses, utilities, and others to use local biomass resources, invest in local energy systems, and reduce the use of fossil heating fuels.

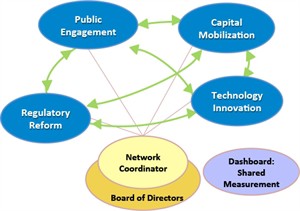

The EAN’s 4 Key Leverage Points of capital mobilization, public engagement, technology innovation, and regulatory reform

The Energy Action Network (EAN) is a community of a community of Green Mountain State stakeholders working to change the Vermont energy landscape “to end Vermont’s reliance on fossil fuels and to create clean, affordable energy and secure electric, heating, and transportation systems for the 21st century.” Their goals are consistent with the State of Vermont 2011 Comprehensive Energy Plan, which aims to meet 90% of Vermont’s energy needs through efficiency and renewable sources by 2050.

EAN has identified a series of pathways for Vermont for Vermont to accomplish the paradigm shift of 90% renewables by 2050. Membership is structured into working groups focused on four “leverage points” capital mobilization, public engagement, technology innovation, and regulatory reform. Current projects include alterations to Act 250, changes in zoning laws, programs to promote bringing rental properties into efficiency standards, and assessing current land use for its potential for bioenergy and solar projects.

One notable awareness vehicle, Brighter Vermont, encourages Vermonters to change the way common energy use and think more about where energy comes from. Read more about how Brighter Vermont helps change energy behavior. EAN also works with municipalities and recently helped Montpelier plan for a 15 year track to become the first state capital to accomplish all of its energy needs with renewable energy. On February 12, 2015 the Montpelier City council accepted and endorsed the plan to make Montpelier a “net zero” city.

Currently, EAN is working with the Vermont Sustainable Jobs Fund to expand the Vermont Energy Atlas website into the Community Energy Dashboard. The Dashboard will enable communities to understand their energy use and make clean energy choices and investments across all energy sectors—heating, transportation, and electricity. The Dashboard will make energy use visible and understandable to consumers and communities by showing town-level progress toward Vermont’s 90% renewables by 2050 goal. The Dashboard will also shows existing and potential renewable energy sites (solar, wind, hydro, biomass). We will provide updates as they develop. Stay tuned into the Vermont Bioenergy Field Notes blog and visit the Energy Action Network website to learn more.

06 Apr 2015

Upcoming North American Bioenergy Events

Make sure to check on the Vermont Bioenergy Initiative website for more national bioenergy events as we will be updating this list!

- May

- June

- WasteExpo 2015 June 1-5, 2015 Las Vegas Convention Center

- 5th International Conference on Algal Biomass, Biofuels and Bioproducts. 7 – 10 June 2015. San Diego, USA

- BIO International Convention June 15-18, 2015. Philadelphia, PA

- Bioenergy 2015,June 23-25. Washington, DC

- GAI AgTech Week June 22-24, 2015 San Francisco, CA

- July

- 19th Annual Green Chemistry & Engineering Conference (GC&E). July 14-16, 2015. N. Bethesda, MD

- BIO World Congress on Industrial Biotechnology. July 19 – 22, 2015. Montreal, Canada

- EnergyPath 2015, July 20-24. Scranton, PA

- BioFuelNet Advanced Biofuels Symposium 2015. July 22 – 24, 2015. Montreal, Canada

- August

- September

- Switchgrass III. September 30 to October 2, 2015. Knoxville, TN

- 2nd International Conference on Past and Present Research Systems of Green Chemistry. September 14-16, 2015. Orlando, Florida

- Ag Innovation Showcase September 14-16, 2015 St. Louis, MO

- Algae Biomass Summit September 30-October 2, 2015 Washington, DC

- October

- November

Nick Meyer of North Hardwick Dairy, an Organic Valley milk producer, was able to reduce energy costs and increase self-sufficiency by growing sunflowers for biodiesel and meal while maintaining a wind turbine to help cover electricity needs.

We all know food gives us energy. But we might sometimes lose sight of the amount of energy involved in producing, processing and delivering that food to our plates. Everything requires energy: from tractors plowing and planting to producing fertilizer or compost; from milking cows and keeping that milk cold to storing and transporting vegetables. This energy costs farms real money and it is sometimes a major category of expense. Energy costs are typically one of the highest for farms, rivaling feed costs on dairy farms and labor costs on vegetable farms.

As Vermont experiences growth in food-related businesses and jobs, decisions about energy become more and more important. This has been part of Vermont’s Farm to Plate Strategic Plan and the associated network of people working on implementing that plan. The plan includes goals related to energy, including; reducing farm production expenses, reducing adverse environmental impacts from farm and food system activities, reducing energy use, and increasing renewable energy use in the food system.

One example of how this is actually working is a group called the Farm to Plate Energy Cross Cutting Team: a group of energy specialists from Efficiency Vermont, the Agency of Agriculture, UVM’s Rubenstein School and UVM Extension, The Vermont Bioenergy Initiative, USDA NRCS and private companies. The team meets regularly to learn from each other and take on specific projects such as the recent set of seven “Energy Success Stories” which were released at the 2014 Farm Show, showcasing farms, businesses, vendors, installers, and technical assistance providers who have made a difference with energy efficiency savings and renewable energy production.

Chaired by Efficiency Vermont planning manager, JJ Vandette, the energy team will continue to address the Farm to Plate Efficiency and Renewable Energy Goal to decrease overall food system energy consumption and increase food system renewable energy production and the Farm to Plate Environmental Impacts Goal to decrease adverse environmental impacts from farming and food system activities—while helping to decrease production expenses—also a goal of the Farm to Plate Strategic Plan.

The team is always interested in having new members. If you have an interest in energy, especially energy on farms and in the food system, we’d love to hear from you. JJ Vandette can be reached at jvandette@veic.org or 802.540.7915.

Data sources and analysis at www.vtfarmtoplate.com/getting-to-2020.

Aegis Renewable Energy a Vermont based renewable energy company designed and installed the first commercial wind turbine in New York City at “Sunset Park” SIMS Municipal Recycling plant in Brooklyn. Aegis erected the 100kW wind turbine in December, 2014 and partnered with Vermont based wind turbine manufacturer, Northern Power Systems located in Barre, Vermont.

The project was recently featured in the New York Times: “In less than a month of operation, the first large-scale wind turbine to be installed in New York City, standing more than 160 feet tall, has produced enough energy to power two homes for over a year, or one 20-watt light bulb for over a century.”

The energy produced from the wind turbine “is expected to provide 4 percent of the energy used by the plant,” the Times article continues. Aegis’ CEO, Nils Behn, was also quoted in the article: “The Sunset Park waterfront’s wide-open nature makes it a prime spot for harvesting wind.”

Aegis won the project through a competitive bid process in 2011 and immediately began the electrical and foundation design process as well as completing various studies including sound and wildlife impact analyses, all of which were critical components in securing grants and permitting for the project.

Aegis has partnered with Northern Power Systems on 15 projects to date, “Northern’s undisputed position as the world leader in the 100kW wind turbine market, and their uncompromising commitment to quality, has been a key component to our success and theirs” said Nils Behn, CEO of Aegis.

During the ribbon cutting ceremony in New York, Northern Power CEO Troy Patton said “Northern Power leverages knowledge from over 400 wind turbine projects around the world to provide installers with training on the best practices for smooth and efficient installations”.

Aegis partners with other Vermont companies, including Green Mountain Credit Union which partnered with Aegis to create a community solar loan program, and the Vermont Sustainable Jobs Fund (VSJF)- Flexible Capital Fund which provided growth stage royalty financing to help Aegis expand its business operation and create more jobs in Vermont’s renewable energy sector.

About Aegis Renewable Energy

Aegis Renewable Energy offers full-service community-scale renewable energy solutions for farms, businesses, non-profits, and municipalities. Wind, Solar and Anaerobic digesters (cow manure and food waste) are included in Aegis’ services designed to help clients save money and the planet. Aegis Renewable Energy is located in Waitsfield, Vermont and provides cost evaluation, permitting, and financing support, installation, and maintenance services throughout Vermont and New England. To learn more about Aegis Renewable Energy, please visit www.aegis-re.com.

About Northern Power Systems

Northern Power Systems designs, manufactures, and sells wind turbines and power technology products, and provides engineering development services and technology licenses for energy applications, into the global marketplace from its US headquarters and European offices. Northern Power Systems has almost 40 years’ experience in technologies and products generating renewable energy. Northern Power Systems currently manufactures the NPS™ 60 and NPS™ 100 turbines. With over 6 million run time hours across its global fleet, Northern Power wind turbines provide customers with clean, cost effective, reliable renewable energy. To learn more about Northern Power Systems, please visit www.northernpower.com.

If you would like more information about this topic, please contact: Sonia Behn 802-496- 5155 or email at sbehn@aegis-re.com.

08 May 2014

Vermont Bioenergy Initiative releases report on grass heating energy potential in Vermont and the Northeast

Baling switchgrass at Meach Cove Farm in Shelburne, Vermont. Photo Credit Vermont Bioenergy Initiative

Montpelier, VT – A new report evaluating grass biomass energy as a potential heating fuel has been released. Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The report was released last week by the Vermont Bioenergy Initiative, a program of the Vermont Sustainable Jobs Fund. The full report can be found on the Vermont Bioenergy Initiative website.

“There have been several independent assessments over the years of the various aspects of growing and burning grass for energy, but we were missing the step of linking it all together. We needed to put into one place what is currently known about grass energy, and get our remaining questions on paper,” says Sarah Galbraith, program manager of the Vermont Bioenergy Initiative. “It is very possible that grass as a heating fuel could enter into Vermont’s growing suite of renewable energy options. There are still uncertainties, but this report provides a series of recommendations and next steps for Vermont and the Northeast.”

The assessment for the report was conducted by members from Wilson Engineering Services and Ernst Conservation Seeds, and a former staff of Pennsylvania State University Cooperative Extension, who together conducted a literature review and interviews with experts in the field. The report was reviewed by the Vermont Agency of Agriculture, Food and Markets, University of Vermont Extension, Biomass Energy Resource Center, and the Vermont Sustainable Jobs Fund.

Grass for biofuels grow at the UVM Hort Farm in South Burlingon, Vermont. Photo credit Vermont Bioenergy Initiative

Grass Energy in Vermont and the Northeast includes key recommendations on models of grass energy that will work best for Vermont. Regional and closed loop processing were two models recommended, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

Despite hurdles in some of the models presented, the report points to grass energy being a good option overall. “Native, warm-season grasses grown as a heating fuel are a viable energy crop for Vermont farmers wishing to diversify. Once the grasses are well-established, the input costs are minimal—especially compared to corn,” states Alexander DePillis, senior agriculture development coordinator for Vermont’s Agency of Agriculture, Food and Markets, an instrumental partner throughout planning for and publishing the grass energy report. “Grass thermal energy has the potential to help cut Vermont’s overall fuel bills while helping us meet the overall goal of the Comprehensive Energy Plan—for Vermont to obtain 90% of its energy from renewable sources by 2050.”

Perennial grasses can be grown on marginal lands not well suited for continuous row crop production and in open rural land currently not in agricultural production. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms. Recommendations include a concerted effort in Vermont to plant grasses for energy on extended buffer strips along Lake Champlain, thereby reducing its nutrient load. Grass is a perennial crop harvested annually that can help level the increasing demand for forest biomass, while adding water quality and wildlife benefits by controlling erosion, reducing fertilizer use and providing cover and food for migrating and nesting birds.

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund to aid in strategic planning for future grass energy program directives. The Vermont Bioenergy Initiative and subsequent grass energy report are funded by appropriations from the US Department of Energy secured by the Office of Senator Patrick Leahy.

The Vermont Bioenergy Initiative (www.vermontbioenergy.com) draws the connection between diversified agriculture and local renewable energy production for on-farm and community use. Aiming to supply farm inputs and reduce fossil fuel consumption, this program supports research, technical assistance, and infrastructure development in emerging areas of bioenergy. Since 2003 the program has focused on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae production for biofuels and wastewater management. The Vermont Bioenergy Initiative is a program of The Vermont Sustainable Jobs Fund, a non-profit organization which provides financing, technical assistance and other resources to Vermont businesses who develop products and services and create jobs in the fields of renewable energy, and sustainable agriculture and forestry.

A report published this week in Nature Climate Change indicated that ethanol made from corn residue can reduce soil carbon and increase CO2 emissions, indicating the harvested leftovers from corn are “worse than gasoline for global warming,” according to the Associated Press, who released the study results.

In Vermont the term “biofuel” and “bioenergy” are commonly used to refer to woody biomass (e.g., chips and pellets), anaerobic digestion (e.g., new manure and food scrap digester at Vermont Tech), and on-farm biodiesel production.

A scale-appropriate model of local bioenergy production for in-state use is being pioneered by farmers and researchers. These emerging renewable energy resources include switch grass for heating, algae production for biofuels and wastewater management, and oilseed crops for on-farm biodiesel production, equipment use, and animal feed. Since 2003, the Vermont Bioenergy Initiative has been funding research, technical assistance, and demonstration projects—along with its partners at the University of Vermont Extension—in order to develop the infrastructure to connect diversified agriculture and local renewable energy production for on-farm and community use. A new website www.VermontBioenergy.com provides a series of written and video resources in these emerging fields of bioenergy.

“Local oilseed biodiesel production for local use is profoundly different from national and international models of biofuel production. While corn-based ethanol and palm oil biodiesel are gaining negative attention for their impacts on the environment and food security, biofuels that are produced and used locally help transition away from unsustainable models of food and fuel production,” states Sarah Galbraith, program manager of the Vermont Bioenergy Initiative. “Local production for local use works well in conjunction with sustainable food production.”

Vermont is particularly dependent on fossil fuels for heating and transportation, sending its energy dollars largely out of state. In the case of locally produced biodiesel, three products can be made from one crop: animal feed, organic fertilizer, and biofuel for heat, transportation, and farm equipment.

US corn-based ethanol mandates are bringing additional acres into mono-crop production, in some cases converting sensitive natural areas like native grasslands and forestland into farmland. In contrast, local bioenergy production for local use incorporates rotational crops like sunflowers and soybeans into acres already in production. Vermont farms growing oilseed crops for biodiesel production are doing so on long-established cropland in the context of diversified and sustainable food production.

The ethanol mandates are raising grain costs nationally, making feed expensive for Vermont dairy farmers. Local bioenergy production, however, means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and at more stable prices.

The Vermont Bioenergy Initiative’s newly launched website features an in depth look at oilseed production and biodiesel operations with case studies, research, and educational videos. The website also features similar resources for grass energy and algae for biofuel and wastewater management as well as information on other biofuels being produced and used in Vermont. www.VermontBioenergy.com

###

The Vermont Bioenergy Initiative draws the connection between diversified agriculture and local renewable energy production for on farm and community use. Aiming to supply farm inputs and reduce fossil fuel consumption, this program supports research, technical assistance, and infrastructure development in emerging areas of bioenergy. Since 2003 the program has focused on biodiesel production and distribution for heating and transportation, oil crops for on-farm biodiesel and feed, grass for heating, and algae for biofuels and wastewater management. The Vermont Bioenergy Initiative works with biodiesel producers including State Line Biofuels and the Farm Fresh Fuel Project at Borderview Farm and grass pellet research through UVM Extension and is supported financially by US Department of Energy congressional appropriations secured by US Senator Patrick Leahy. The Vermont Bioenergy Initiative is a program of the Vermont Sustainable Jobs Fund—a non-profit organization created by the Vermont Legislature in 1995 to accelerate the development of Vermont’s green economy in the fields of renewable energy, sustainable agriculture and forestry.