In early 2014 Full Sun Company, a small start-up business was co-founded by Netaka White and Davis McManus. Fueled by an interest to help family farms grow, Full Sun began processing sunflower and non-GMO canola oil crops into specialty food-grade oil and high-protein meal for the farmers. Sunflower and canola oil distribution picked up quickly through local CSAs, farm stores, specialty food shops, health and wellness centers, and direct sales to chefs in the Northeast.

Netaka White previously served as the Vermont Bioenergy Initiative’s (VBI) program director, which directly helped to develop the business model to nurture farm partnerships, both as growers and recipients of oilseed meal – the other product that’s generated from making the oil. At Full Sun oilseeds are pressed with large mechanical machinery, producing oil and a granular meal. The team at Full Sun Company learned a lot about seed storage and oil pressing from the early VBI grantees, such as John Williamson of State Line Farm, and Roger Rainville of Borderview Farm.

The first of the two products, the seed meal, has been used as fuel for pellet stoves, or as is the case with Full Sun, sold as fertilizer for crops, or nutritional meal for livestock. At full operation, Full Sun can pump out one ton of meal per day – necessary to meet the growing demand of such customers as The Intervale in Burlington, Vermont and several local pig, poultry, dairy, and beef producers.

Full Sun Company employee, Zach Hartlyn, moves an off-spec oil barrel for biodiesel production

Credit: Full Sun Company

The second product, the oil, is used as culinary oil for cooking. Staying true to their commitment to an extraordinary culinary product, Full Sun Company diverts any of the oil that does not meet their standards to Vermont Bioenergy Initiative biofuel producers to undergo further processing and become biofuel. Approximately 250-300 gallons of off-spec oil for biodiesel has been processed since February, 2014.

In October, 2014, Full Sun Company halted operation to make room for growth to meet the increased demand for their products and scale up to align with Vermont’s accelerating agricultural economy. White and McManus acquired the former Vermont Soap building in Middlebury, Vermont in order to build a full scale mill and achieve their anticipated greater capacity. Over the course of one of the coldest winters in recent history, the Full Sun team made the renovations and adjustments needed to repurpose the building into the first non-GMO verified oil mill in New England. By March of 2015 Full Sun Company had pressed sunflower and canola seeds to make their first batch of specialty oils. The new operation can yield 130 gallons of oil per day – about 2600 gallons per month!

With no shortage of innovation or ambition, White notes, “David and I are in this with the interest of having a transformative effect on local agriculture and food systems.” Well on their way, the operation is certified GMO free, and the next steps are being taken towards becoming certified organic.

As they grow, Full Sun would like to buy from local grower-suppliers and work with local businesses to package and label feed to be distributed to farmers of varying sizes, from backyard chicken growers to larger operations. Collaborating with Vermont breweries and distilleries is also in queue. Full Sun is working with one local distillery to put together “a package” for farmers so they have markets for profitable grain crops throughout four years of rotation (rye, wheat, sunflowers, etc.) and can offer farmers the indexed prices for these locally grown grains and oilseeds.

27 Jul 2015

Summit on Creating Prosperity and Opportunity Confronting Climate Change – Looking Back and Looking Forward

The Summit on Creating Prosperity and Opportunity Confronting Climate Change brought together over 400 innovative business, non‐profit, and community leaders, elected officials, public policy advocates, students, and interested residents to begin to frame policy and investment strategies to advance the development of the Vermont Climate Economy. Summit participants developed a list of key practical actions to serve as a launching point for the Vermont Climate Change Economy Council (VCCEC), a group charged with a one year mission to develop a structured plan with practical actions to reduce carbon emissions and stimulate green economic development in Vermont. The Council will build a set of public/private strategies designed to promote economic opportunity, innovative business development, investment, and job creation in Vermont.

The Summit on Creating Prosperity and Opportunity Confronting Climate Change brought together over 400 innovative business, non‐profit, and community leaders, elected officials, public policy advocates, students, and interested residents to begin to frame policy and investment strategies to advance the development of the Vermont Climate Economy. Summit participants developed a list of key practical actions to serve as a launching point for the Vermont Climate Change Economy Council (VCCEC), a group charged with a one year mission to develop a structured plan with practical actions to reduce carbon emissions and stimulate green economic development in Vermont. The Council will build a set of public/private strategies designed to promote economic opportunity, innovative business development, investment, and job creation in Vermont.

Over the course of 2015, VCCEC will evaluate findings, key ideas and suggested action steps derived from the Summit, lead regional public forums, evaluate and summarize research findings, interview key stakeholder groups, and consider model economic development strategies from other state and countries. During 2015, the group will develop a strategic platform of recommendations for action, and report to the Vermont legislature, the Governor of Vermont and the public in January 2016. The Vermont Council on Rural Development (VCRD) will provide support to their work and then help promote the platform of action that comes from its deliberants. Goals of the Vermont Climate Change Economy Council are to:

- Identify opportunities created by climate change to strengthen Vermont’s economy through strategies advancing key business clusters and economic sectors.

- Build an increased sense of unity in Vermont around policies to confront and mitigate the impact of climate change and to advance economic opportunities and solutions that respond to climate change.

- Build a public information campaign to celebrate innovation and Vermont’s green business leadership; internally and externally marketing to build the Vermont brand as an economic/environmental problem solver.

- Expand Vermont’s economic brand around climate change solutions to retain and attract youth and creative entrepreneurs to locate throughout the state.

Vermont businesses and nonprofits are addressing climate change – both its challenges and opportunities. Their creative solutions are a growing part of our state’s economy. What are your experiences? Do you have ideas about how Vermont can grow jobs and nurture innovative business development in sectors ranging from clean energy, to recycling, transportation systems, and thermal efficiency?

Jo![Regional_Forum_Flyer5_15_statewide[1]](https://vermontbioenergy.com/wp-content/uploads/2015/07/Regional_Forum_Flyer5_15_statewide1-150x150.jpg) in the Vermont Council on Rural Development and local business leaders at a forum on “What’s Next for Vermont’s Climate Change Economy?” Forums will take place at 7:00pm at the Paramount in Rutland (Aug 26), the Latchis Hotel in Brattleboro (Oct 6), and City Hall in Burlington (Oct 29). Come to the forum(s) most convenient for you.

in the Vermont Council on Rural Development and local business leaders at a forum on “What’s Next for Vermont’s Climate Change Economy?” Forums will take place at 7:00pm at the Paramount in Rutland (Aug 26), the Latchis Hotel in Brattleboro (Oct 6), and City Hall in Burlington (Oct 29). Come to the forum(s) most convenient for you.

These forums are the next step for public input to the Vermont Climate Change Economy Council, a group working to develop a practical plan to reduce carbon emissions and stimulate economic development in Vermont. To learn more about the forums and the Council visit VCRD’s website at vtrural.org, download the event flyer (pdf).

For more information about the results of the summit, Click HERE to read the report and follow the hashtag #VTClimateEconomy and Vermont Council on Rural Development on Twitter at @VTRuralDev for more updates!

Farms open their doors to a public interested in learning more about where food comes from and supporting the local agricultural economy

Farmers across Vermont will throw open their barn doors and garden gates to welcome the public for a behind-the-scenes look at Vermont’s vibrant working landscape. Vermont’s first Open Farm Week will be held Monday, August 3 – Sunday, August 9, 2015.

Open Farm Week is a weeklong celebration of Vermont farms. Over 100 farms are participating, many of whom are not usually open to the public. Open Farm Week offers Vermonters and visitors alike educational opportunities to learn more about local food origins, authentic agritourism experiences, and the chance to build relationships with local farmers. Activities vary and may include milking cows and goats, harvesting vegetables, collecting eggs, tasting farm fresh food, scavenger hunts, hayrides, farm dinners, and live music.

Visit DigInVT for a map of participating farms by region. Many events are free and costs vary depending on what activities are offered. Everyone is invited to join the #VTOpenFarm conversations on social media. All participating farms, geographic location, and offerings are at www.DigInVT.com.

Farmers’ markets will also be a part of the Open Farm Week celebration as organizers planned the event to coincide with National Farmers’ Market Week – also the first week of August.

The first Vermont Buy Local Market on the Statehouse Lawn will be held during Open Farm Week on Tuesday, August 4th from 10am-1pm. The Vermont Agency of Agriculture, Food and Markets is organizing the first Statehouse farmers’ market in collaboration with the Capital City Farmers’ Market and NOFA-VT.

Building off of the success of NOFA-VT’s 2014 Open CSA Farm Day, Open Farm Week is a collaborative statewide agritourism project organized by members of the Vermont Farm to Plate Network including Intervale Center, Vermont Farm Tours, Neighboring Food Co-op Association, Vermont Agency of Agriculture, Vermont Fresh Network, Vermont Department of Tourism, Shelburne Farms and Farm-based Education, NOFA-VT, and City Market. Open Farm Week helps Vermont reach its statewide Farm to Plate food system plan goals to increase farm profitability, local food availability, and consumption of Vermont food products.

Vermont Open Farm Week is made possible by the generous support of Premiere Sponsor: City Market/Onion River Coop as well as the Vermont Department of Tourism and Marketing; Vermont Agency of Agriculture, Food and Markets, Localvore Today and Woodchuck Hard Cider.

13 Jul 2015

Making Biofuel

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

Making biofuel, it sounds like a complicated process taking place in a laboratory somewhere, but in reality it’s quite simple and happening in small, rural Vermont farms. Vermont farmers like John Williamson of State Line Farm and others are electing to create their own fuel and meal. These farmers are enjoying the benefits of the distance to source resiliency and cost reliability that comes with the local production for local use biofuel model they have adopted.

As John Williamson, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.” This is a novel way to look at what he is doing on his North Bennington farm. Vermont farmers in the past would plan to allocate their acreage to feed their livestock, some of which aided in energy-intensive farm activities like plowing, planting, and the eventual harvesting of their field. With the local production for local use model, John is now thinking about how to feed his tractor so he can do the same activities. So what is the feed of choice for John’s John Deer tractor? Sunflowers!

John loads dry and clean sunflower seeds into hoppers on a TabyPressen Oilpress, where screw augers push the seed through a narrow dye. Extracted oil oozes from the side of the barrel and is collected in settling tanks while pelletized meal is pushed through the dye at the front and is stored in one-ton agricultural sacks. The first of the two byproducts, the seed meal, can fuel pellet stoves, serve as fertilizer for crops, or find its way to local Vermont farms to supplement animal nutrition as livestock feed. The second byproduct, the fuel, could at this point be used as culinary oil for cooking, but instead will experience further refinement and become biofuel.

The processing of the oil takes place in Johns self-designed Biobarn. In the below video, John Williamson and Chris Callahan of University of Vermont Extension show us how they can grow oil crops, make biodiesel, feed animals, and save money!

Have something to say about Vermont’s energy future? The Public Service Department (PSD) is seeking public input on its update to Vermont’s long-range Comprehensive Energy Plan. They want to hear Vermonters’ thoughts on how the state can meet its energy goals – and energy needs – in the coming years. They are holding four public forums in regions across the state in July at the following dates and locations;

Have something to say about Vermont’s energy future? The Public Service Department (PSD) is seeking public input on its update to Vermont’s long-range Comprehensive Energy Plan. They want to hear Vermonters’ thoughts on how the state can meet its energy goals – and energy needs – in the coming years. They are holding four public forums in regions across the state in July at the following dates and locations;

- July 9 – Woodstock (Billings Farm and Museum)

- July 16 – Middlebury (Town Hall Theater)

- July 20 – Manchester (Manchester Community Library)

- July 23 – St Albans (Bellows Free Library)

The comprehensive plan, which was last updated in 2011, will also incorporate some of the findings of the Total Energy Study, completed by the PSD last year. One of the PSD’s goals for the updated plan is to establish nearer-term targets that balance technology constraints, cost, carbon considerations and community concerns. The PSD will also host a series of forums, soliciting further public input, when a draft is available. These dates and times can be found below.

Public Hearings Schedule – All Hearings Run from 6 p.m.-8 p.m.

-

October 7 – Lyndonville

- Lyndon State College , Moore Community Room (campus map)

- From College Road, continue past Lower Campus Drive (it will be on your left) and continue straight through the four-way intersection, up the hill. Take the first left into the Vail parking lot. Enter doors at the end of the building; Moore Community Room is immediately to your left (#11 on the campus map).

- Lyndon State College , Moore Community Room (campus map)

-

October 13 – Essex

- Essex High School, Cafeteria (map)

-

October 21 – Montpelier

- Vermont College of Fine Arts (map), Noble Hall (campus map)

-

October 26 – Bellows Falls

- Bellows Falls Union High School, Auditorium (map)

-

October 29 – Rutland

- Rutland Regional Medical Center (map), CVPS/Leahy Community Health Education Center (location details)

Find more details or comment online here: http://www.energyplan.vt.gov

29 Jun 2015

Soybeans for On-farm Biodiesel Production

Mark Mordasky, owner of Rainbow Valley Farm in Orwell, Vermont has been growing soybeans as a cash crop and for on-farm biodiesel and animal feed since 2008. When fuel prices began to climb, Mark took initiative and started searching for an innovative and more cost efficient way to meet his farm’s energy demands. The Vermont Sustainable Jobs Fund was able to help Mark take his first steps towards sustainable biofuel production. Mark is able to press these soybeans after harvesting and make two distinct products, oil and meal. The meal is an instantly marketable product and can be sold as feedstock or organic fertilizer; the oil will be further processed into biodiesel.

Soybeans crops are well suited for biodiesel production in Vermont and perform best in heavy soil like those found in Addison County, as University of Vermont Extension Agronomist, Heather Darby explains. Soybeans don’t always do well in in light, well drained soils, and as with any crop the best way to understand the demands of any crops is to contact your University Extension and have your soil tested. Additionally, because soybeans are a legume, they produce nitrogen in association with bacteria, meaning that these crops don’t require the application of additional nitrogen to produce a high yield. These low input, high yield crops are fairly easy to grow, are well suited to the Vermont climate, and afford farmers flexible planting dates. Heather and the rest of the UVM Extension team have seen yields ranging from 35 bushels per acre to up to 85 bushels per acre with varying practices.

In the below video, Mike Mordasky shares his experience and knowledge of soybean production from planting through harvesting harvest and beyond to storage and the creation of the final products. In addition, Heather Darby shares here insights into maturity groupings, variety selection, and best growing practices.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

With funding from the US Department of Energy secured by US Senator Patrick Leahy, the Vermont Bioenergy Initiative has supported a number of algae biofuel research projects. This early-stage research and development was undertaken to determine the most viable and cost-effective methods for accessing algae’s commercial potential to produce clean renewable energy while treating wastewater and supplying nutrient-rich feeds and food.

Algae produces more than half of the oxygen on the planet, while consuming vast amounts of heat-trapping carbon dioxide and taking up nutrients like nitrogen and phosphorous to make biomass and energy. The lipids, or oil, that algae produce can be extracted and processed into renewable fuels such as biodiesel. Algae are an excellent source of oil for making biodiesel, which could displace substantial volumes of petro-diesel for heating and transportation. Microalgae reproduce rapidly, and they grow on non-agricultural land, so they do not compete with food, feed, or fiber production.

The keys to commercializing algae for biofuel production include identifying and cultivating native species, optimizing growing conditions in natural and artificial environments and the efficient harvest and oil extraction of algal biomass. At the forefront of this algae biofuel research is Dr. Anju Dahiya, cofounder of General Systems Research, LLC, lead biofuels instructor at the University of Vermont’s Rubenstein School of Environment and Natural Resources, and Vermont Bioenergy algae for biofuel grant recipient. Dr. Dahiya has been searching for high lipid algae strains, and scaling those up to a level that could be available for commercial use, especially for biofuels.

“At GSR Solutions, we are looking at producing algae not just for biofuels, but combining it with waste water treatment and to produce other valued byproducts as well. This is very significant, because this would make algae production cost-effective. This would also help in nutrient recovery,” says Dahiya.

innovative new textbook that provides insight into the potential and current advances and benefits of biofuel

Some of the findings and knowledge afforded by Dr. Dahiya’s research are available in the new introductory textbook, Bioenergy: Biomass to Biofuels, which was edited by Anju Dahiya less than a year ago and represents a compilation of work from an extensive list of well-respected university extension programs, such as The University of Vermont Research Extension, as well as numerous national organizations including the US Department of Energy’s National Renewable Energy Laboratories. Dr. Dahiya will also be using this textbook as the basis for a University of Vermont Bioenergy Course offered for the 2015 fall semester.

In the below video, Vermont researchers and entrepreneurs demonstrate their innovations in algae to biofuel research and development.

For more algae bioenergy resources see the visit the Algae section of the Vermont Bioenergy Website.

Learn more about the mentioned UVM Bioenergy Course visit the University of Vermont Renewable BioEnergy page or email the lead instructor Anju Dahiya at adahiya@uvm.edu.

For more information on the introductory textbook Bioenery; Biomass to Biofuels see our write up on the book here!

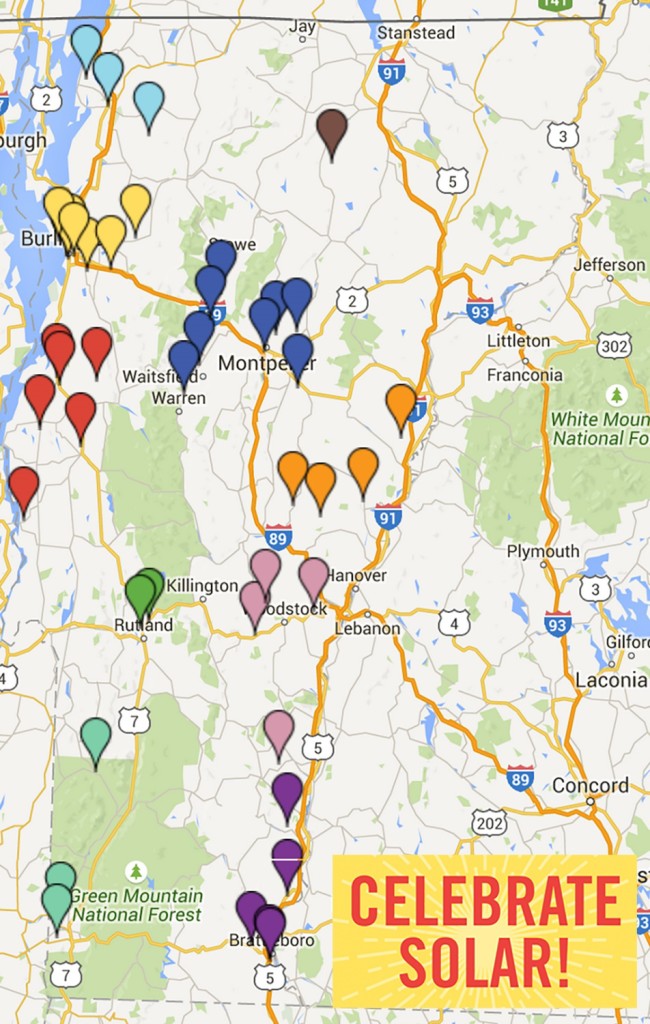

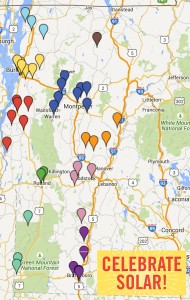

Vermont’s solar industry is lauding Governor Peter Shumlin’s proclamation of the third Saturday in June as “Celebrate Solar Day” in Vermont.

The solar proclamation, announced at the Whitcomb Farm in Essex, coincides with this June 20th, when solar projects in communities throughout Vermont will be open for public tours. June 20 is the weekend of the Summer Solstice.

Like open sugarhouse weekend in the spring and open art studio weekend in the fall, the inaugural summertime tours will give Vermonters the opportunity to get an up-close view of solar systems to learn about the technology, solar economics, and the benefits of solar to our community. Solar customers, host farmers, and owners will be on-hand to speak with the public.

More than 50 systems across all regions of the state will be participating in Celebrate Solar Tours and a map of open tours can be found here. Many participating sites will host refreshments, music, or other entertainment. Other planned solar events include community walking tours of residential solar installations, miniature golf, a self-guided bike tour, and on-site yoga.

The Governor’s proclamation notes that “solar energy represented 99% of new electrical capacity in the state in 2014 and more than 5,000 Vermont customers have installed solar” through Vermont’s net metering program.

Further, it cites that the Vermont clean energy industries employ over 15,000 Vermonters, with solar providing “a broad spectrum of employment opportunities, helping retain and attract Vermonters working in manufacturing, installation, and sales, among other careers.”

The Whitcomb family is host to a 2.2 Megawatt solar farm that provides energy for Vermont’s SPEED program.

Among the solar sites open to tour June 20: iconic and sweet Vermont attractions like Cold Hollow Cider and Morse Farm Maple Sugarworks, high-tech attractions like Draker and Small Dog Electronics, agricultural farms like Champlain Orchards, shared community solar arrays, and some of Vermont’s highest producing solar farms.

At the announcement of the solar tours, Paul Brown, owner of Cold Hollow Cider in Waterbury Center, which has a 150kW system powering its operations, said of the event, “Folks know us and visit us for our cider and donuts. But we are thrilled to open up the field behind our cidery to share the benefits of solar technology to our business and our community. We’ll of course also be serving up some sweet treats for those who come by.”

About Celebrate Solar Tours – June 20

The first annual Celebrate Solar Tours on June 20 will feature public tours of more than 50 solar systems of varying size throughout the state. The public will have the opportunity to get an up-close understanding of the technology, economics and benefits to the community. Open systems will be designated with roadway signage and many will feature music, refreshments or other entertainment.

Contact: Ansley Bloomer

Ansley@revermont.org or 802-595-0723

08 Jun 2015

Grass Energy in Vermont

University of Vermont Extension Agronomist, Sid Bosworth explains in the field his research into use of grasses for combustion and thermal energy

In 2008, the Vermont Bioenergy Initiative began to explore the potential for grasses energy grown in Vermont to meet a portion of the state’s heating demand and reduce the consumption of non-renewable fossil fuels. The Grass Energy in Vermont and the Northeast report was initiated by the Vermont Sustainable Jobs Fund, and carried out by its program the Vermont Bioenergy Initiative, to aid in strategic planning for future grass energy program directives.

Grass Energy in Vermont and the Northeast summarizes current research on the agronomy and usage potential of grass as a biofuel, and points to next steps for the region to fully commercialize this opportunity. The keys to commercializing grass for energy are improving fuel supply with high-yielding crops, establishing best practices for production and use, developing appropriate, high-efficiency combustion technology, and building markets for grass fuel.

Perennial grasses, while serving as a biomass feedstock for heating fuel, also have numerous other benefits to farmers. The grass energy benefits reviewed in the report include retaining energy dollars in the local community, reducing greenhouse gas emissions from heating systems, improving energy security, providing a use for marginal farmland, and reducing pollution in soil and run-off from farms.

Regional and closed loop processing were two models recommended by the report, both involving farmers growing and harvesting grass, but differing in where the grass is processed into fuel and where it is used. The regional processing model calls for aggregating grass from a 50-mile radius at a central processing facility, where the grass is made into and used as fuel, or sold to local users. The closed loop model suggests farmers growing and processing grass on-site for on-farm or community use. Other models, like mobile on-farm processing and processing fuel for the consumer pellet market have significant hurdles to overcome if they are to be successful in Vermont.

In the below video a Vermont agronomist explains switchgrass production followed by entrepreneurs turning bales of grass into briquette fuel. This grass biofuel feedstock can be grown alongside food production on marginal agricultural lands and abandoned pastures, and in conserved open spaces. The harvested grass can be baled and used as-is in straw bale combustion systems, or it can be compressed into several useable forms for pellet fuel combustion systems.

For more information on grass biofuel feedstocks and to read the full Grass Energy in Vermont and the Northeast report visit the grass energy section of the Vermont Bioenergy website.

01 Jun 2015

Food Versus Fuel – Local Production for Local Use – Biodiesel as Part of Sustainable Agriculture

Nationally, corn-based ethanol and palm oil based biodiesel are gaining negative attention for their impacts on the environment and food security. But here in Vermont, farms are producing on-farm biodiesel to power equipment and operations on the farm and the local farm community. This is a profoundly different model from national and international biofuel production. Agricultural Engineering and Agronomy Researchers at University of Vermont Extension in partnership with farmers and the Vermont Bioenergy Initiative have developed a model of local minded, on-farm production of biofuels that can help rural communities transition away from unsustainable models of food, feed and fuel production.

National and global models of corn-ethanol and soy oil-biodiesel production are resulting in large-scale land conversions in some parts of the world, in particular to a loss of native grass and forestland. This type of biofuel production is not happening in Vermont, where bioenergy production incorporates rotational oilseed crops like sunflowers and soybeans on Vermont farms.

Locally produced biodiesel supports resiliency in Vermont, a cold climate state which is particularly dependent on oil. Over $1 billion leaves the state for heating and transportation fuel costs. Heating and fuel independence by producing on-farm biodiesel provides farmers fuel security which is comparable to that which is sought by Vermont’s local food movement.

The local production for local use model results in two products from one crop: oil and meal (animal feed or fertilizer). By growing oilseed and pressing the seed to extract the oil, farms are creating a valuable livestock feed at home, rather than importing it. The oil can be sold as a food product, used directly in a converted engine or converted to biodiesel for use in a standard diesel engine. In this way, oilseed crops offer flexibility in the end-use of the products. US corn-based ethanol mandates are raising grain costs nationally, making feed expensive for Vermont farmers. Local bioenergy production means farmers produce their own feed, fuel, and fertilizer for on-farm use, at a fraction of the cost and more stable prices. Reduced and stable prices for feed, fuel, and fertilizer can mean improved economic viability for Vermont farms and more stable food prices for Vermont consumers in the future.

Overall viability can be seen in the local production for local use model by considering economics, energy and carbon emissions. Biodiesel production costs of between $0.60 and $2.52 per gallon have been estimated for farm-scale production models, which are generally below market price for diesel fuel. The net energy return in Vermont on-farm biodiesel operations has been estimated at between 2.6 and 5.9 times the invested energy (i.e. more energy out than was required to produce the fuel), demonstrating strong returns and potential for improvement with increased scale. Furthermore, oilseed-based production of biodiesel has been estimated to result in a net reduction of carbon dioxide emissions of up to 1420 lbs. per acre, the equivalent of about 1500 miles of car travel per year.

Categorizing the Vermont biofuel model with national models and trends is inaccurate, considering the innovative and efficient systems benefiting Vermont farmers. While national and international analysis weighs the benefits of food versus fuel, the model is quite unique in Vermont and the food versus fuel challenge is well met. The model developed in Vermont does however have wider-reaching implications in that this can be replicated in rural farm communities across the US.

As John Williamson of Stateline Farm, a Vermont Bioenergy grant recipient says, “100 years ago everyone produced their own fuel; we are just doing that now in a different way.”